Soil improvement slow-release compound fertilizer and preparation method thereof

A slow-release compound fertilizer and soil improvement technology, which is applied in the field of soil improvement slow-release compound fertilizer and its preparation, can solve the problems that the amount of farmyard manure cannot meet large-scale use, the spread of pathogenic microorganisms, and nitrogen loss, etc., to improve the quality of crops , improving soil and protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A slow-release compound fertilizer for soil improvement, made from the following raw materials in parts by weight: 30 parts of zeolite, 10 parts of corn cobs, 10 parts of wheat straw, 5 parts of animal manure, 5 parts of plant ash, 9 parts of oyster powder, and 10 parts of seaweed powder , 3 parts of humic acid, 7 parts of urea, 8 parts of alginate, 3 parts of potassium sulfate, 3 parts of ammonium dihydrogen phosphate, 3 parts of potassium phosphate, 3 parts of sodium silicate, 3 parts of calcium chloride, 3 parts of potassium nitrate , 1 part of trace elements, 1 part of vitamins, 10 parts of amino acid powder.

[0021] The preparation method of the oyster powder is as follows: washing oyster shells with water to remove surface silt and attachments, drying at 55°C for 1.5 hours, pulverizing the oyster shells to 2-3mm into oyster shell slag, and sending the oyster shell slag to the grinder for further processing. Grind to 200-300nm to get oyster powder. The preparatio...

Embodiment 2

[0028] The difference from Example 1 is that a soil improvement slow-release compound fertilizer is made of the following raw materials in parts by weight: 40 parts of zeolite, 15 parts of corn cobs, 15 parts of wheat straw, 10 parts of animal manure, 8 parts of plant ash, oyster 11 parts of seaweed powder, 13 parts of seaweed powder, 5 parts of humic acid, 10 parts of urea, 10 parts of alginate, 5 parts of potassium sulfate, 5 parts of ammonium dihydrogen phosphate, 5 parts of potassium phosphate, 5 parts of sodium silicate, 5 parts of calcium, 5 parts of potassium nitrate, 2 parts of trace elements, 2 parts of vitamins, 15 parts of amino acid powder.

Embodiment 3

[0030] The difference from Example 1 is that a soil-improving slow-release compound fertilizer is made of the following raw materials in parts by weight: 35 parts of zeolite, 13 parts of corn cobs, 12 parts of wheat straw, 8 parts of animal manure, 6 parts of plant ash, oyster 10 parts of seaweed powder, 12 parts of seaweed powder, 4 parts of humic acid, 9 parts of urea, 9 parts of alginate, 4 parts of potassium sulfate, 4 parts of ammonium dihydrogen phosphate, 4 parts of potassium phosphate, 4 parts of sodium silicate, 4 parts of calcium, 4 parts of potassium nitrate, 1.5 parts of trace elements, 1.5 parts of vitamins, 12 parts of amino acid powder.

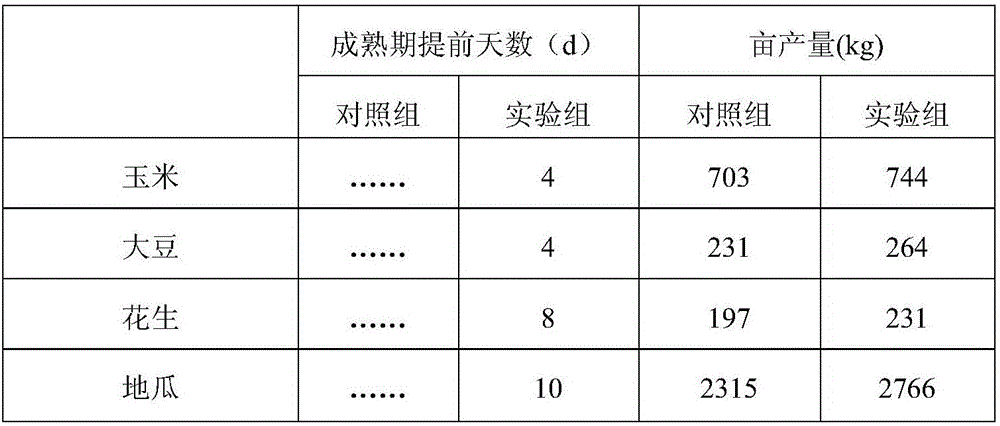

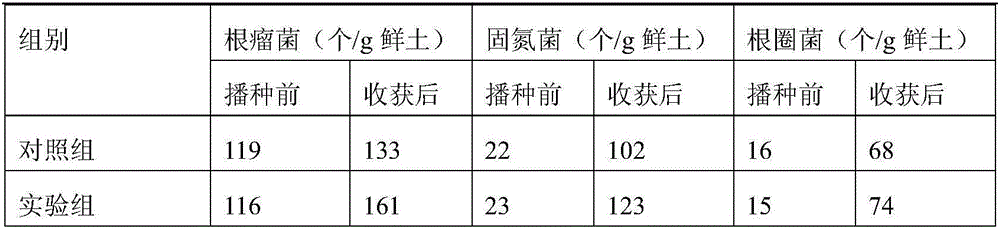

[0031] Verification test one

[0032]Use the soil improvement slow-release compound fertilizer of the present invention as the experimental group, and simultaneously use commercially available common urea fertilizer as the fertilizer application of the control group; use soybeans, corn and sweet potatoes as application objects,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com