Mesoporous silicon, preparation method of same, and method of photolyzing water to produce hydrogen

A technology of mesoporous silicon and mesoporous silicon dioxide, applied in the field of mesoporous silicon and its preparation, can solve the problems of reducing the active sites on the surface of the material, poor crystallinity of mesoporous silicon materials, and limiting the transmission of photocharges, and achieves excellent results. The performance, good crystallinity, and enhanced charge separation of photo-splitting water for hydrogen production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

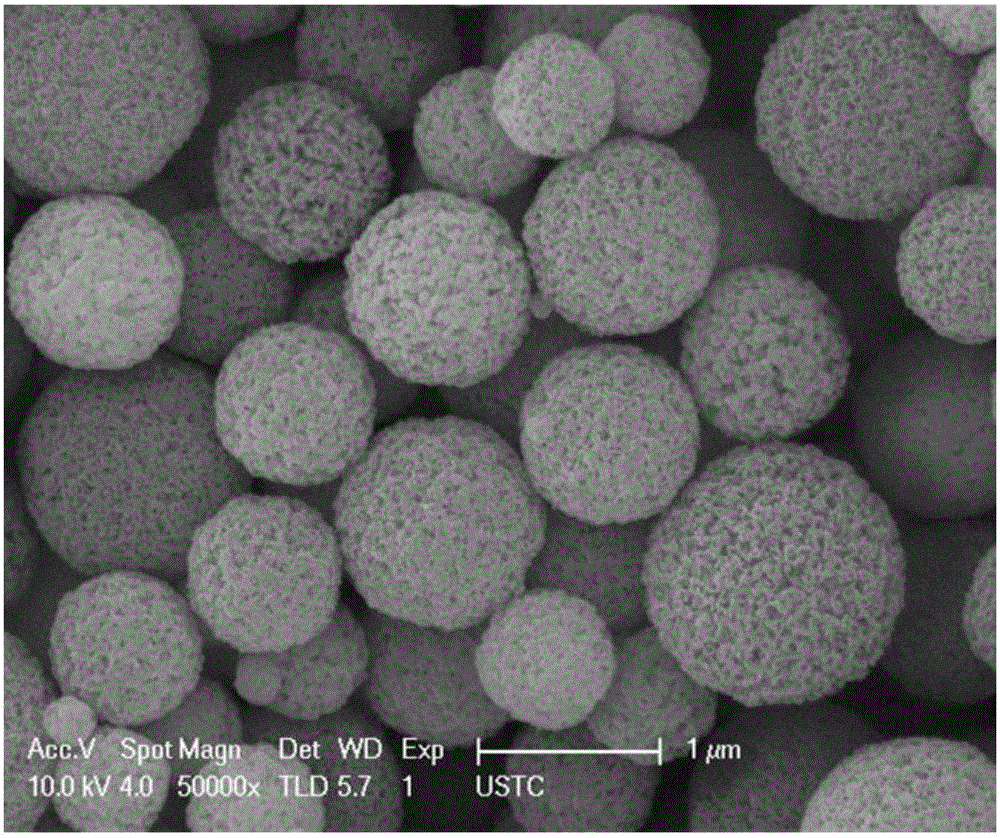

[0028] The invention provides a method for preparing mesoporous silicon, comprising: S1) mixing colloidal silica and low-temperature eutectic salt in water to obtain a silica reaction solution; S2) subjecting the silica reaction solution to Atomization to obtain atomized droplets; S3) heat-treating the atomized droplets to obtain mesoporous silica; S4) mixing the mesoporous silica with magnesium powder, After being calcined in the atmosphere, it is immersed in an acid solution to obtain mesoporous silicon.

[0029] The present invention uses colloidal silicon dioxide as the silicon source, and the cost is far lower than the silicon wafers required for anodic oxidation and staining and corrosion.

[0030] Mix colloidal silicon dioxide and low-temperature eutectic salt in water to obtain silicon dioxide reaction liquid. Wherein, the low-temperature eutectic salt can be a low-temperature eutectic salt well known to those skilled in the art, and there is no special limitation. In...

Embodiment 1

[0047] 2.054g of sodium nitrate and 1.437g of lithium nitrate were dissolved in 26.55mL of deionized water to prepare a low-temperature eutectic salt solution, and 3.45mL of colloidal silica (Ludox TM-40, a product of Sigma-Aldrich) The suspended aqueous solution is added to the low-temperature eutectic salt solution to form a 1mol / L silica reaction solution. After the reaction solution is ultrasonically dispersed for 5 minutes, it is then transferred to an ultrasonic atomizer. The frequency of the ultrasonic atomizer is 1.7 MHz.

[0048] The outlet of the ultrasonic atomization generator is connected with the inlet of the tube furnace, and the outlet of the tube furnace is connected with the product collection container. Using argon as the carrier gas with an airflow rate of 0.4L / min, the atomized liquid droplets are brought into a tube furnace at 500°C for heating and reaction, and the generated product enters the collector along with the airflow. The solution in the collec...

Embodiment 2

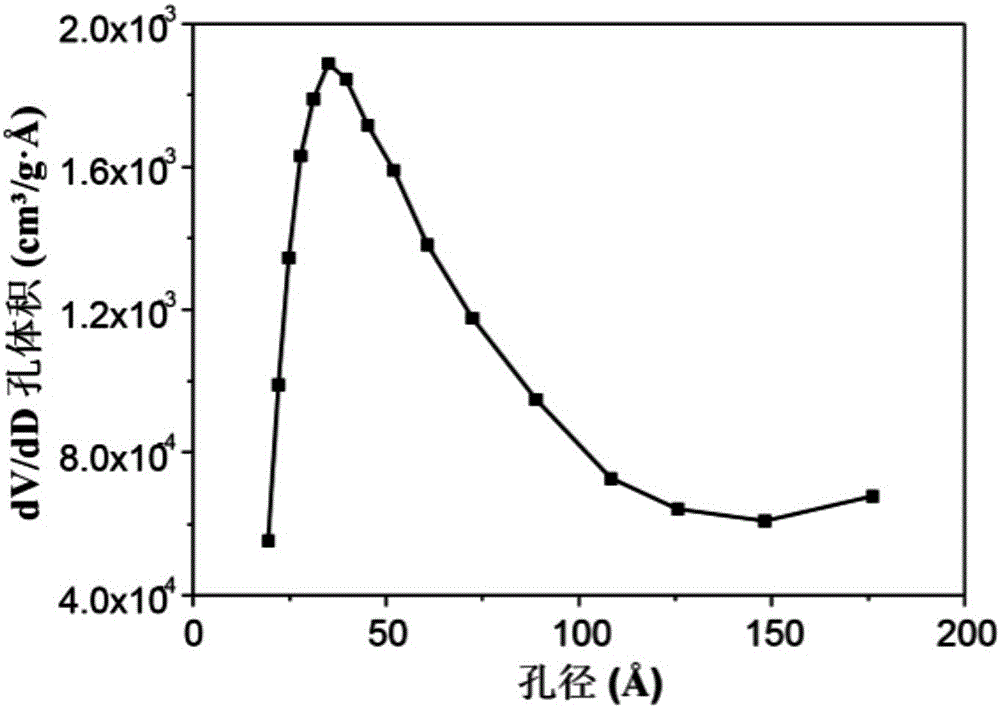

[0052] Prepared according to the preparation method in Example 1, only changing the ratio of the amount of the low-temperature eutectic salt to the amount of silicon dioxide to 1:1, you can get a specific surface area of 60m 2 / g of mesoporous silica.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com