Clamping head for full-automatic hydroelectric engineering drain pipe

A fully automatic, drainpipe technology, used in conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of wheeled vehicles difficult to enter, low handling and stacking efficiency, dangerous safety accidents, etc. Easy, fast and safe to take and stack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

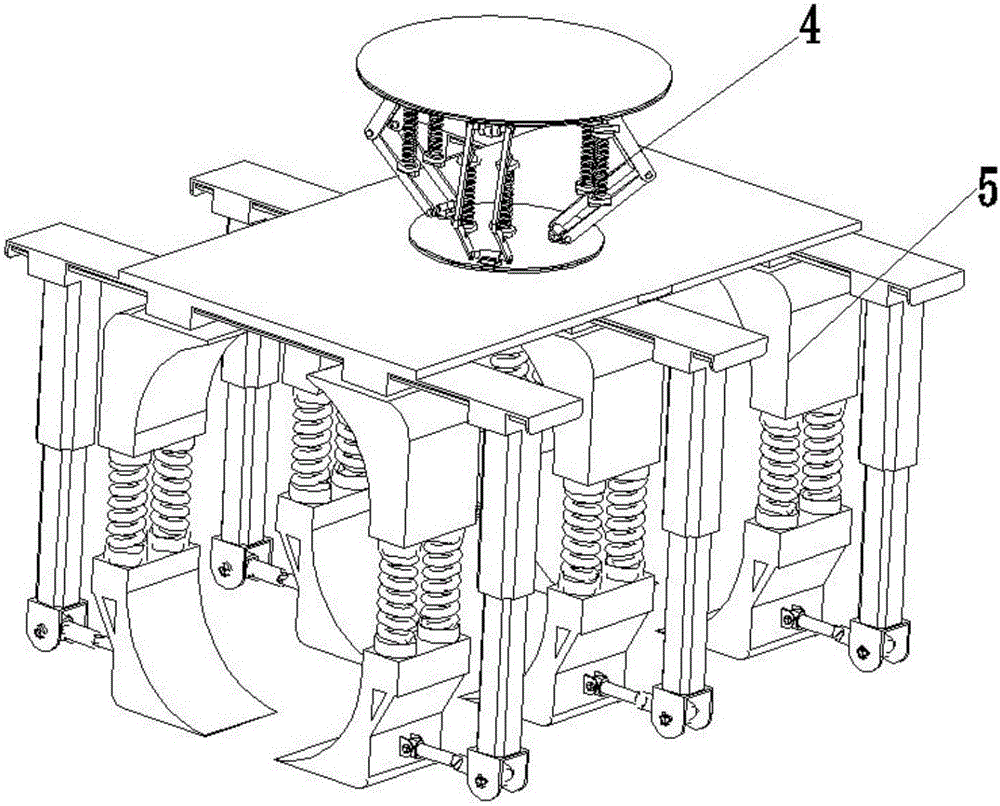

[0019] Such as Figure 1 to Figure 4 As shown, a fully automatic water conservancy power generation project drainage pipe clamping head includes a delta parallel mechanism 4 and a clamping device 5; the delta parallel mechanism 4 is located directly above the clamping device 5, and the lower end of the delta parallel mechanism 4 is connected to the clamp The holding device 5 is connected.

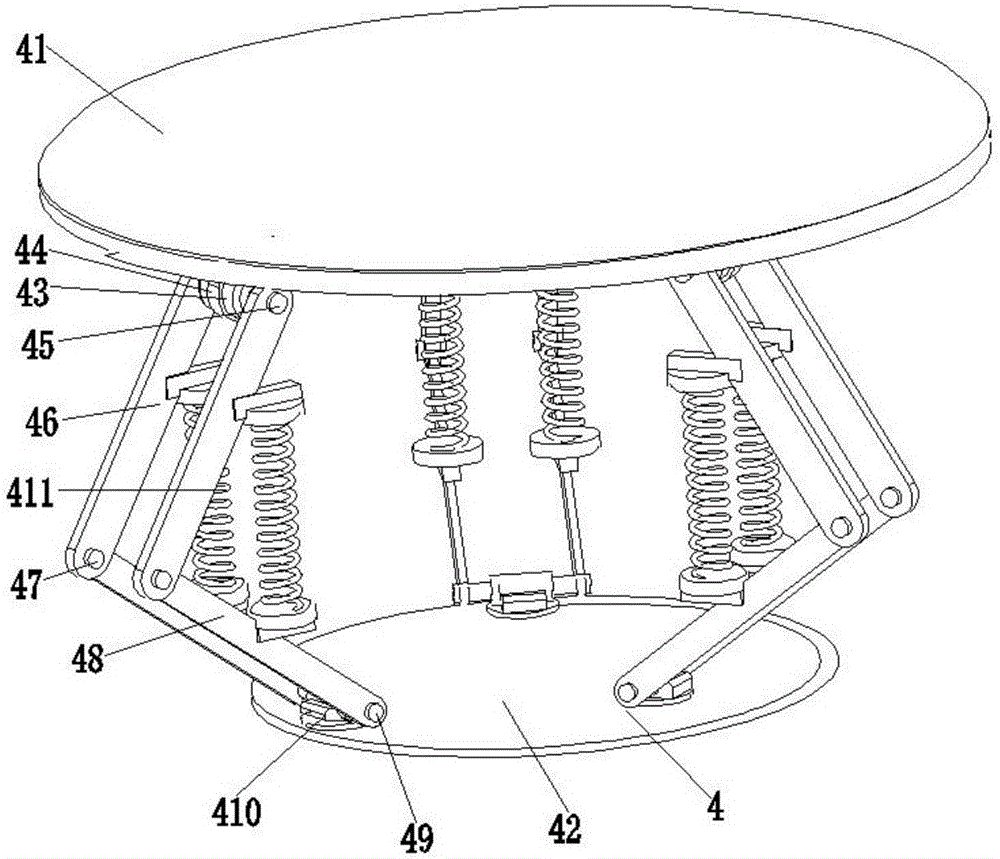

[0020] Such as figure 1 and figure 2 As shown, the delta parallel mechanism 4 includes a fixed platform 41, a moving platform 42, a motor seat 43, a parallel motor 44, a first rotating shaft 45, a first connecting rod 46, a rotating pin 47, a second connecting rod 48, a second Rotating shaft 49, rotating base 410 and limit spring 411; Described fixed plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com