The technology of shunting and shunting of the continuous tractor with the infinite rope in the multi-level transportation inclined road in the mine

A tractor and multi-level technology, applied in the field of shunting cars, can solve problems such as bending and breaking of curved rails at branch roads, potential safety hazards, and deformation of rails, so as to reduce lateral force, safe and efficient shunting, The effect of improving transportation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

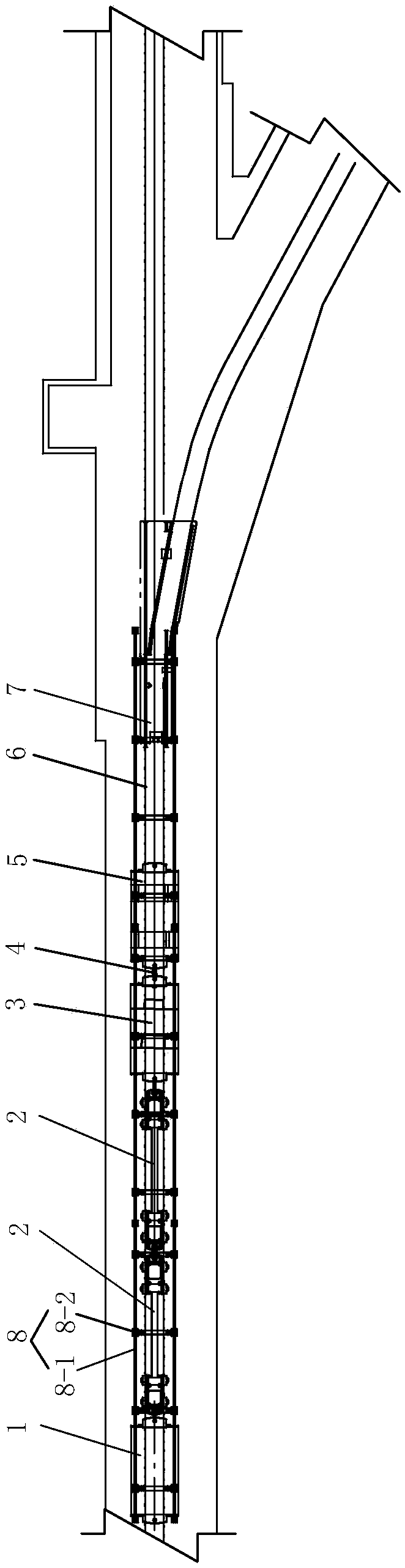

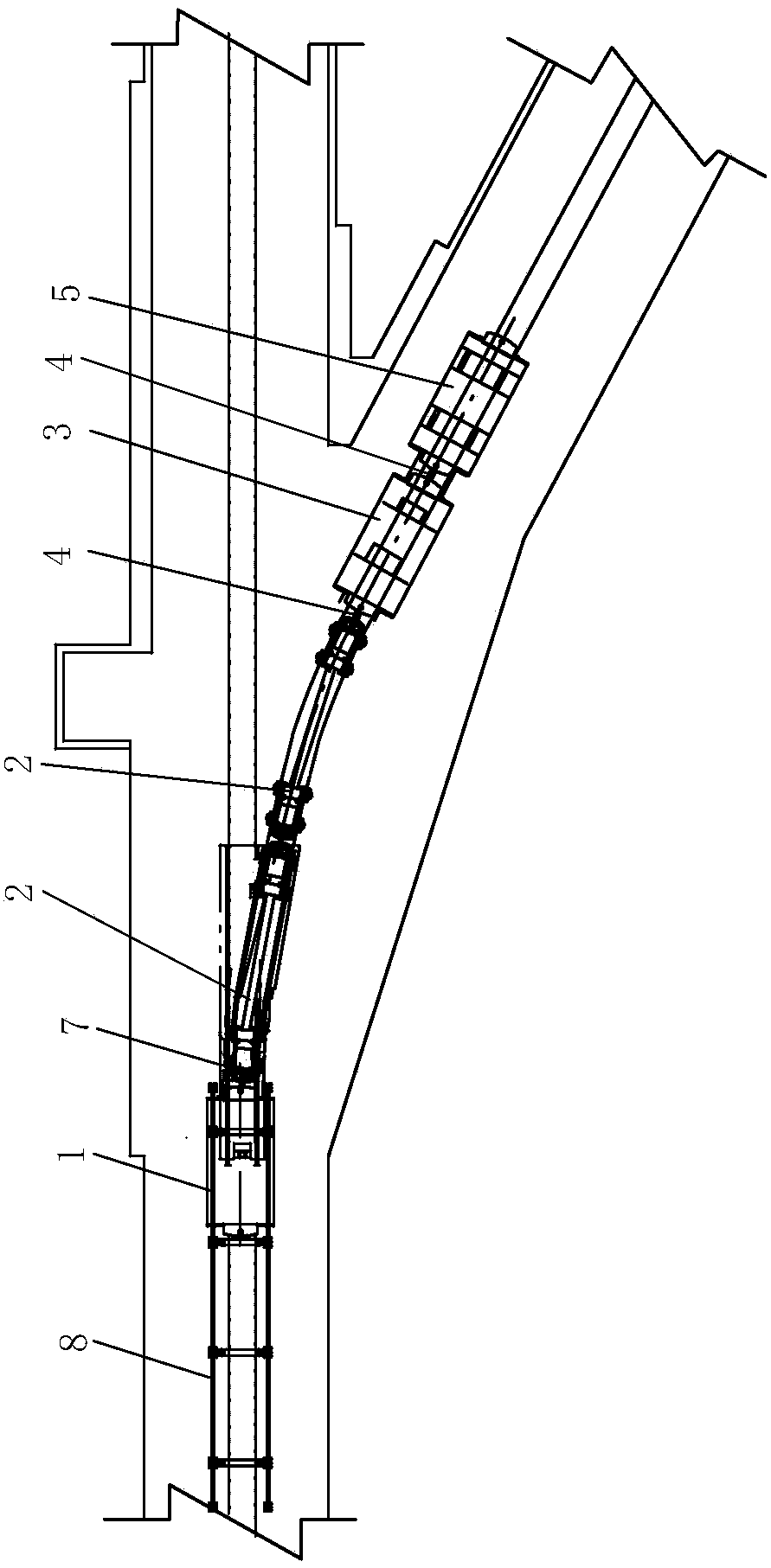

[0026] See Figure 1 to Figure 8 , Embodiment 1 includes train and ditching turnout 7.

[0027] The vehicle train includes a tractor 1 , more than one connecting rod car 2 , a brake car 3 and more than one cargo car 5 . The maximum number of connecting rod cars 2 allowed in the train is determined according to the specific conditions of the roadway.

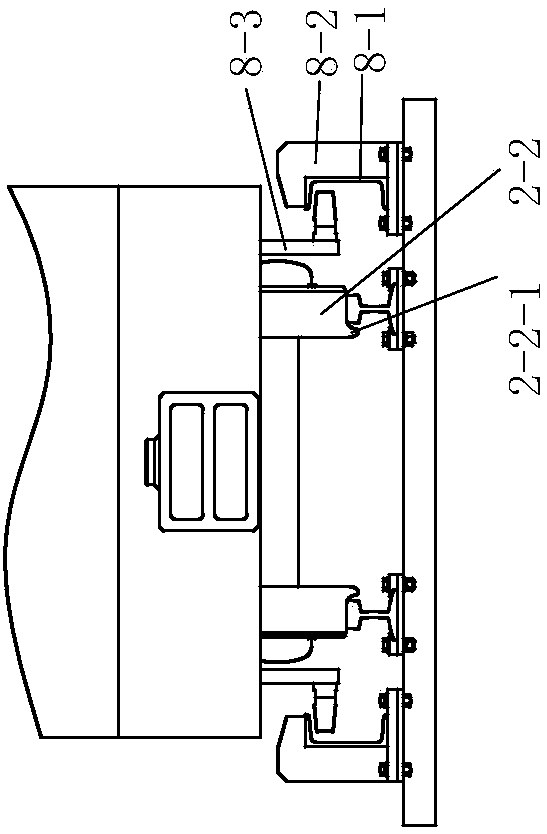

[0028] The linked vehicle 2 has two vehicle frames 2-1, and the bottom of each vehicle frame 2-1 is provided with two pairs of road wheels 2-2. A long connecting rod 2-3 longer than 5 meters is arranged between the two vehicle frames 2-1. The vehicle frame 2-1 is fixed with a ball joint frame 2-5, and the ball joint frame 2-5 is provided with a ball joint 2-4, and the ball joint 2-4 includes a ball joint cover 2-4-1 and a ball joint body 2- 4-2, the ball hinge sleeve 2-4-1 is positioned by the end cover 2-6, and the two ends of the long connecting rod 2-3 are respectively inserted into the ball hinge body 2-4-2 of the two vehi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com