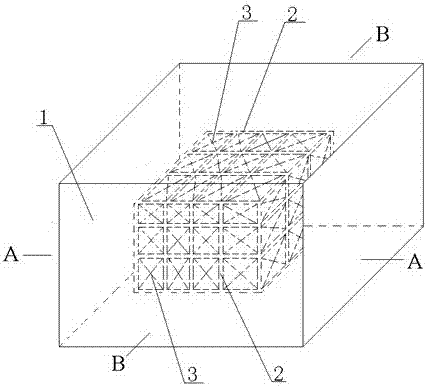

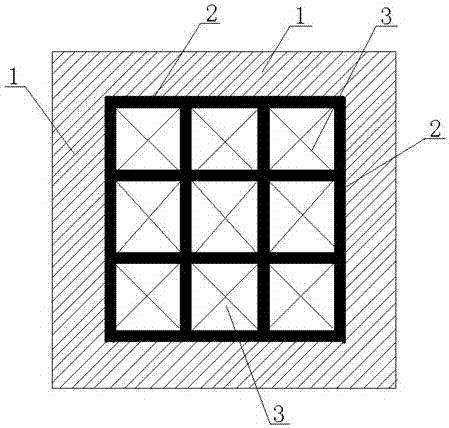

A kind of honeycomb structure plastic-wood composite material plate and preparation method thereof

A wood-plastic composite material and honeycomb structure technology, applied in chemical instruments and methods, synthetic resin layered products, layered products, etc. , inconvenient installation and other problems, to achieve the effect of light weight, high rigidity and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1: A kind of preparation method of honeycomb structure wood-plastic composite board, its preparation process is:

[0041] (1) Mix the wood flour and isocyanate that have been vacuum-dried at 100°C for 5 hours to constant weight in a small high-speed mixer for 20 minutes, then add stearic acid and continue mixing for 20 minutes at 100°C, the mass ratio of wood flour:stearic acid:isocyanate For 100:6:4, obtain 120 mesh modified wood flour;

[0042] (2) After blending polypropylene, modified wood powder, EPDM, and antifungal agent, extrude and granulate to form wood-plastic composite material particles. The temperature of the extrusion barrel is 190°C, and the temperature of the die is 190°C;

[0043] (3) Lay plastic-wood composite material particles at the bottom of the mold cavity, pressurize it into a 4mm thick plate;

[0044] (4) Take the FRP grating whose length and width are both smaller than the length and width of the mold cavity, and use the plate pres...

Embodiment 2

[0048] Embodiment 2: a kind of preparation method of honeycomb structure wood-plastic composite board, its preparation process is:

[0049] (1) Mix wood flour and isocyanate, which have been vacuum-dried at 100°C for 5 hours to constant weight, in a small high-speed mixer for 10 minutes, then add stearic acid and continue mixing for 10 minutes at 100°C, the mass ratio of wood flour:stearic acid:isocyanate For 100:5:3, obtain 40 mesh modified wood flour;

[0050] (2) Blend polyethylene plastic particles, modified wood flour, POE, and antifungal agent to extrude and granulate to form wood-plastic composite material particles. The temperature of the extrusion barrel is 170°C, and the temperature of the die is 175°C;

[0051] (3) Lay plastic-wood composite material particles at the bottom of the mold cavity, pressurize it into a 3mm thick plate;

[0052] (4) Take the FRP grating whose length and width are both smaller than the length and width of the mold cavity, and use the plat...

Embodiment 3

[0056] Embodiment 3: A kind of preparation method of honeycomb structure wood-plastic composite board, its preparation process is:

[0057] (1) Mix the wood flour and isocyanate, which have been vacuum-dried at 100°C for 5 hours to constant weight, in a small high mixer for 30 minutes, then add stearic acid and continue mixing for 30 minutes at 100°C, the mass ratio of wood flour: stearic acid: isocyanate For 100:7:5, obtain 200 mesh modified wood flour;

[0058] (2) Blend ABS plastic particles, modified wood flour, EPDM, and antifungal agent, extrude and granulate to form wood-plastic composite material particles. The temperature of the extrusion barrel is 210°C, and the temperature of the die is 205°C;

[0059] (3) Lay plastic-wood composite material particles at the bottom of the mold cavity, pressurize it into a 5mm thick plate;

[0060] (4) Take the FRP grating whose length and width are both smaller than the length and width of the mold cavity, and use the plate pressed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com