Assembly process of tower sections for large-diameter wind-power tower tube

A wind power tower tube and large-diameter technology, which is applied in the direction of manufacturing tools, metal processing equipment, auxiliary devices, etc., can solve the problems of uneven stress at the butt joints of tower sections, inconformity with modern production, and low work efficiency, so as to reduce quality risks , reduce stress concentration points, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the examples.

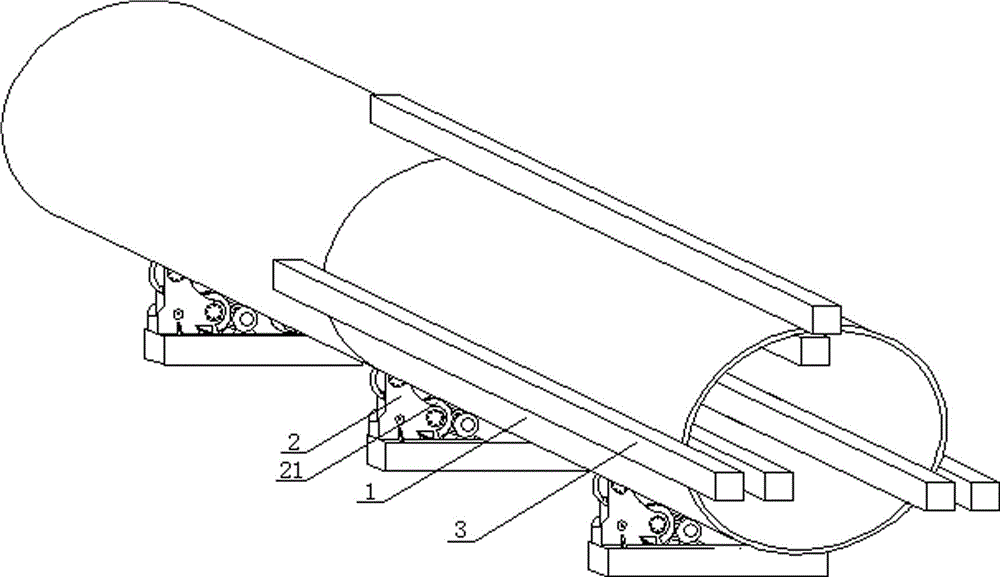

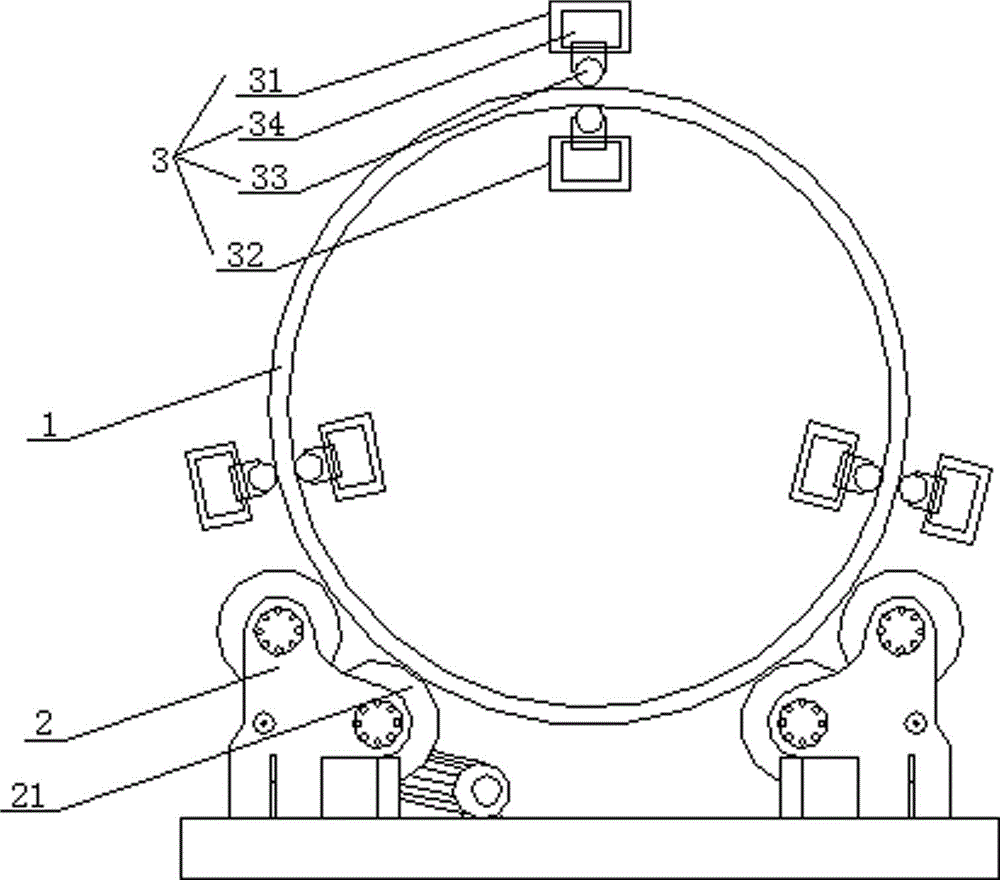

[0018] refer to Figure 1-2 , a process for combining tower sections for large-diameter wind power towers, the specific steps are as follows:

[0019] (1) Place the two tower sections 1 to be paired on the corresponding paired roller frame 2 through the corresponding moving device, adjust the docking position to ensure that the centerlines of the two tower sections correspond to each other, and the paired roller frame 2 There are two sets of supporting rollers, one of which is the main driving roller 21, and the driving capacity of the main driving roller 21 is at least 60t;

[0020] (2) Push three sets of crocodile pairing machines 3 with rollers into the tower section 1 at equal angles. The crocodile pairing machines 3 of the rollers all include a palate 31 and a lower jaw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com