Preparation method and application of organic sulfur conversion catalyst

A catalyst and organosulfur technology, applied in the field of organosulfur conversion catalyst preparation, can solve the problems of many impurities, harsh reaction conditions, time-consuming, etc., and achieve the effects of mild reaction conditions, short reaction time, and simplified workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

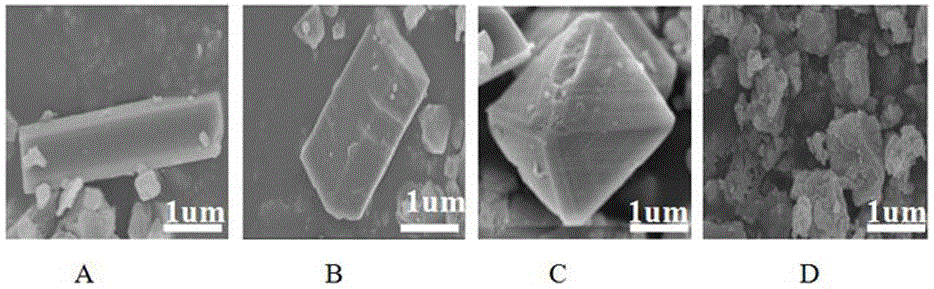

Embodiment 1

[0025] 240 mL of 75% ethanol aqueous solution, 1.75 g of organic ligand H 3 BTC and 2.8 g of supporting electrolyte TBAP were added to the beaker, ultrasonicated for 10 min, and the ultrasonic power was 100 W to make them uniformly dispersed and dissolved; the metal Cu block (99.9998% purity) was used as an electrode, and the circuit was connected to ensure the distance between the two electrodes was 5 cm, and reacted for 3 h under the condition of circuit voltage of 15 V; the obtained product was washed with ethanol and water three times respectively, and dried at 100 °C for 24 h, followed by static vacuum at 120 °C After treatment for 12 h, the metal-organic framework material Cu-MOF (HKUST-1) was finally obtained.

Embodiment 2

[0027] 240 mL of 75% ethanol aqueous solution, 1.75 g of organic ligand H 3 BTC and 2.8 g of supporting electrolyte TBAP were added to the beaker, ultrasonicated for 10 min, and the ultrasonic power was 100 W, so that it was uniformly dispersed and dissolved;

[0028] Metal Cu block (purity: 99.9998%) was used as an electrode, and the circuit was connected to ensure that the distance between the two electrodes was 5 cm, and the reaction was performed under the condition of a circuit voltage of 20 V for 3 h. The obtained product was washed three times with ethanol and water respectively, dried at 100 °C for 24 h, and then treated under static vacuum conditions at 120 °C for 12 h, and the metal organic framework material Cu-MOF (HKUST-1 ).

Embodiment 3

[0030] 240 mL of 75% ethanol aqueous solution, 1.75 g of organic ligand H 3 BTC and 2.8 g of supporting electrolyte TBAP were added to the beaker, ultrasonicated for 10 min, and the ultrasonic power was 100 W, so that it was uniformly dispersed and dissolved;

[0031]A metal Cu block (purity of 99.9998%) was used as an electrode, and the circuit was connected to ensure that the distance between the two electrodes was 5 cm, and the reaction was performed under the condition of a circuit voltage of 25 V for 3 h. The obtained product was washed three times with ethanol and water respectively, dried at 100 °C for 24 h, and then treated under static vacuum conditions at 120 °C for 12 h, and the metal organic framework material Cu-MOF (HKUST-1 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com