Splash-proof foam agent based on Gemini quaternary ammonium salt surfactant and preparation method for same

A technology of surfactants and quaternary ammonium salts, applied in the field of sanitary products, can solve the problems of undisclosed foam stability, no bactericidal and disinfecting ingredients, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

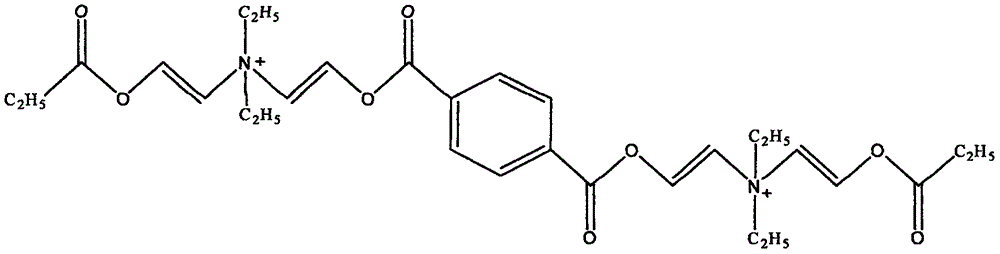

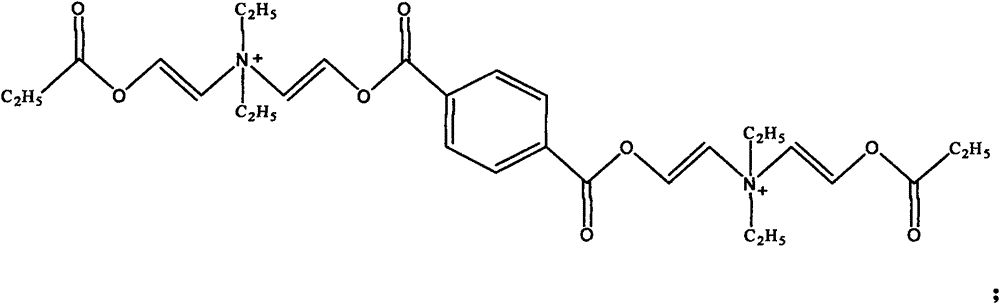

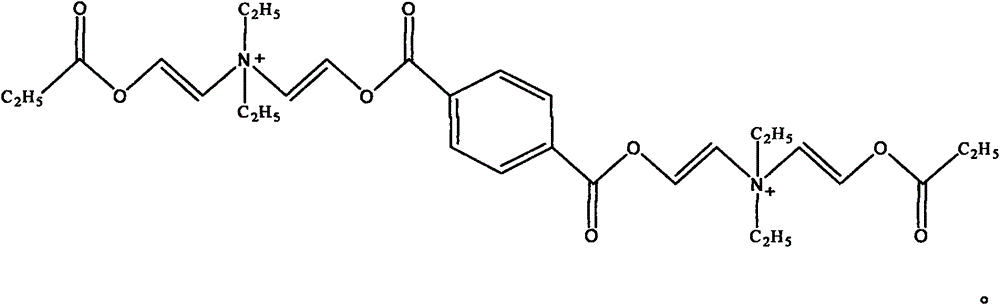

[0034] The preparation method of the Gemini quaternary ammonium salt surfactant shown in the following formula, concrete steps are as follows:

[0035]

[0036] 1) Mix 0.1mol propionic acid and 0.12mol NC 2 h 5 (CH=CHOH) 2 After mixing evenly, put it into the reflux device, add 50mL cyclohexane, 0.1g p-toluenesulfonic acid, 0.3g zinc powder, and reflux reaction at 110°C for 4 hours. Dry over sodium sulfate, evaporate the solvent in a rotary evaporator to obtain a residue, and then purify by column chromatography to obtain propionic acid-N-ethyl divinyl alcoholamine monoester with a yield of 94%;

[0037] 2) Mix 0.05mol of propionic acid-N-ethyldivinolamine monoester with 50mL of chloroform, add 5mL of triethylamine, and cool, then dropwise add a mild solution of 0.025mol of terephthaloyl chloride and 30mL of chloroform, After about 2 hours of dropping, after the dropping, stir and react at room temperature for 20 hours. After the reaction, the reaction solution is washed...

Embodiment 2

[0041] (1) A splash-proof foaming agent based on Gemini quaternary ammonium salt surfactant, it is characterized in that, is made up of following composition, comprises Gemini quaternary ammonium salt surfactant 5% as shown in embodiment 1 structural formula, stable Foaming agent bisethanolamide cocoate 0.1%, thickener sodium hydroxymethylcellulose 5%, emulsifier polysorbate-80 0.5%, foaming agent cocamidopropyl betaine 20%, propellant liquefied propane 3%, 10% of sterilizing detergent lauryl dimethyl benzyl ammonium bromide, 5% of verbena powder as an anti-taste additive, and deionized water as the balance, the sum of the contents of the above components is 100%.

[0042] (2) the preparation method of above-mentioned anti-splash foam agent:

[0043] 1) Take raw materials according to the following formula, such as Gemini quaternary ammonium salt surfactant 5% shown in the structural formula of Example 1, foam stabilizer coconut oleic acid bis-ethanolamide 0.1%, thickener sodi...

Embodiment 3

[0049] (1) A splash-proof foaming agent based on Gemini quaternary ammonium salt surfactant, it is characterized in that, is made up of following composition, comprises Gemini quaternary ammonium salt surfactant 5% as shown in embodiment 1 structural formula, stable Foaming agent bisethanolamide cocoate 0.1%, thickener sodium hydroxymethylcellulose 5%, emulsifier polysorbate-80 0.5%, foaming agent cocamidopropyl betaine 20%, propellant liquefied propane 3%, 10% of sterilizing detergent lauryl dimethyl benzyl ammonium bromide, 5% of verbena powder as an anti-taste additive, and deionized water as the balance, the sum of the contents of the above components is 100%.

[0050] (2) the preparation method of above-mentioned anti-splash foam agent:

[0051] 1) Take the raw materials according to the following formula, such as Gemini quaternary ammonium salt surfactant 10% shown in the structural formula of Example 1, foam stabilizer coconut oleic acid bis-ethanolamide 0.1%, thickener...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Critical micelle concentration | aaaaa | aaaaa |

| Surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com