High-density hollow micro-needle array based on negative photoresist and manufacturing technology thereof

A negative photoresist and manufacturing process technology, which is applied in the field of high-density hollow microneedle arrays and its manufacturing process, can solve the problems of limited convenience, skin and muscle damage, and large microneedle gaps, so as to avoid drug oxidation or pollution , Improving the conveying efficiency, and the effect of simple process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] What the negative photoresist of the present invention adopts is SU-8 photoresist.

[0050] Below in conjunction with accompanying drawing, the invention is described in further detail. It should be understood that the specific embodiments described here are only used to explain the present invention, and are not intended to limit the present invention.

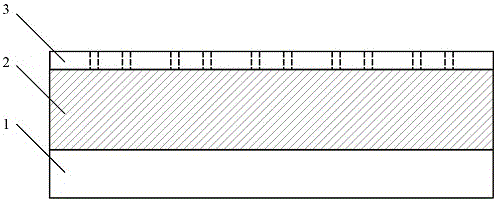

[0051] The preparation process of the high-density hollow microneedle array based on negative photoresist according to the present invention is as follows: figure 1 As shown, the specific steps are as follows:

[0052] The first step is to make the needle body. The production of the needle body consists of 8 steps. From bottom to top, the bottom layer of the needle body, the middle layer of the needle body, and the top layer of the needle body are photolithographically shaped, and finally the preparation of the "needle base module" is completed under the action of a chemical developer.

[0053] Step 1: Prepare Subst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com