Laminating and forming method of white fabric, manufacturing method of shoe fabric and shoes

A production method and fabric technology, applied in the direction of shoe-making machinery, chemical instruments and methods, synthetic resin layered products, etc., can solve the problems of manual folding, difficult to handle, easy to turn yellow, etc. The effect of reducing labor and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0019] The present invention is realized like this, a kind of white fabric pasting forming method, it comprises the following steps:

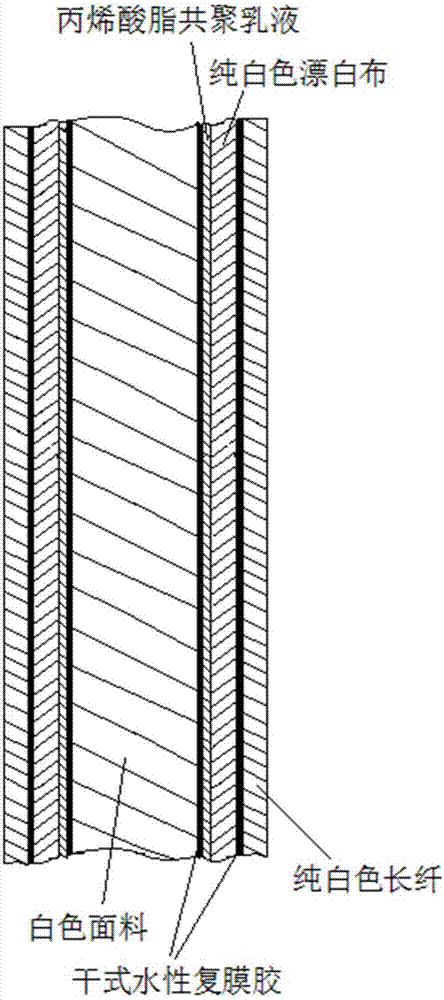

[0020] (1) Take a white fabric as the base material, first apply dry-type water-based laminating adhesive, and then apply a layer of anti-yellowing after the dry-type water-based laminating adhesive is completely dry (after 4-5 minutes). acrylate copolymer emulsion;

[0021] (2) Then stick one deck of pure white bleached cloth on the acrylate copolymer emulsion layer, and then brush dry-type water-based laminating glue on the pure white bleached cloth;

[0022] (3) Paste a layer of pure white long fibers on the dry-type water-based laminating glue of pure white bleached cloth, and paste them to obtain a formed white fabric, such as figure 1 shown. The method has a simple process, can produce a whole sheet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com