Method for efficient FPC board division

A high-efficiency, board-splitting technology, applied in the processing of insulating substrates/layers, electrical components, printed circuit manufacturing, etc., can solve problems such as unfavorable cost savings, inconvenient use and maintenance, and heavy mold weight, to achieve improved processing Efficiency, reduction of equipment input costs, and the effect of reducing equipment input costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

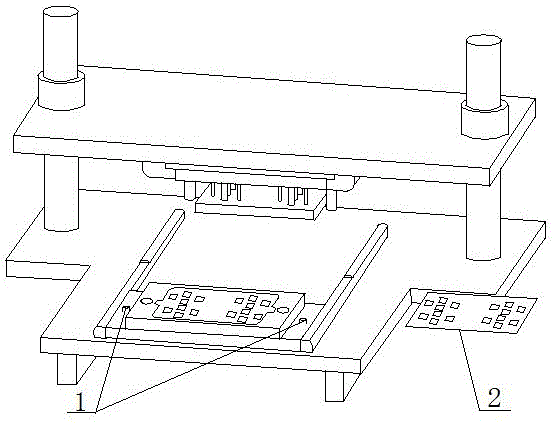

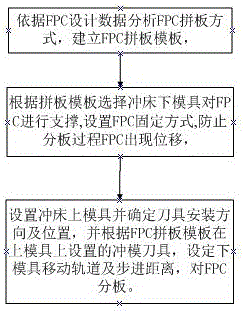

[0015] A method for high-efficiency FPC board splitting. According to the FPC design data analysis of the FPC board-up method, the establishment of the FPC board-up template, according to the board-up template, the mold under the punch press is selected to support the FPC, and the FPC fixing method is set to prevent the appearance of the FPC during the board-breaking process. Displacement, set the mold on the punching machine and determine the installation direction and position of the tool, and set the moving track and step distance of the lower mold according to the punching tool set on the upper mold of the FPC panel template, and divide the FPC.

[0016] According to the above method, the present invention will be further described in conjunction with the accompanying drawings.

[0017] A method for high-efficiency FPC board splitting, which analyzes the FPC board-up method based on FPC design data, and establishes an FPC board-up template, wherein the Gerber file can be us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com