Shell of assembly body for assembling lithium battery and metal frame

A metal frame and assembly technology, applied to battery pack parts, circuits, electrical components, etc., can solve problems such as temperature deviation mismatch, brittleness, and inability to adapt to temperature ranges, so as to buffer shock and improve vibration resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

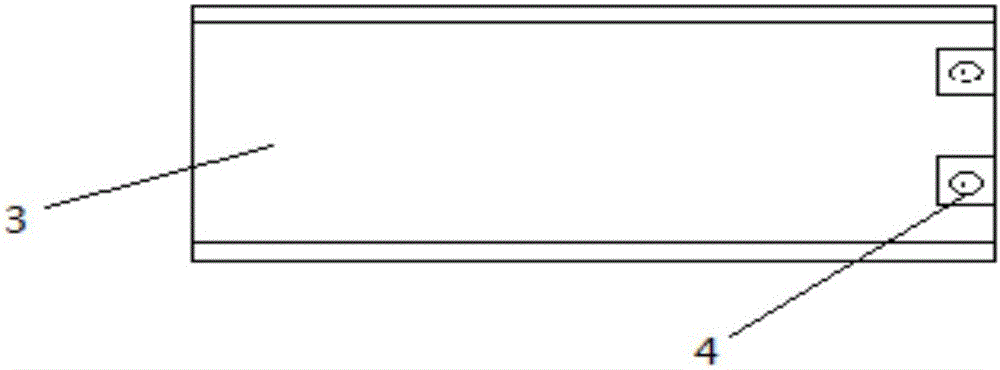

[0033] Such as Figure 3A and Figure 3B As shown, in the prior art, the metal frame used for assembling lithium batteries includes: two metal plates 5 of the same specification and arranged in alignment, for clamping the battery pack therebetween, and above the battery pack on each metal plate Pairs of through holes are respectively arranged in alignment with the strip-shaped area below, for allowing the limit screw 6 to lean against the corresponding battery and pass through each pair of through holes to expose both ends. As an example, the limiting screw 6 is composed of a main section and the two ends, wherein the diameter of the main section is larger than the diameter of the through hole, and the diameter of the through hole is larger than the diameter of the two ends. The logarithm of the through holes in each area above and below is n times the number of rows of the battery pack, and n is an integer greater than or equal to 1, so that the top and bottom of each row of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com