Solar photovoltaic module

A solar photovoltaic and module technology, applied in photovoltaic power generation, electrical components, semiconductor devices, etc., can solve the problems of affecting the reflection effect of the mirror reflection part, the reflection effect is not good, and the power generation efficiency is reduced, so as to improve the heat reflectivity and radiation insulation The effect of improving power generation efficiency and improving the effect of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

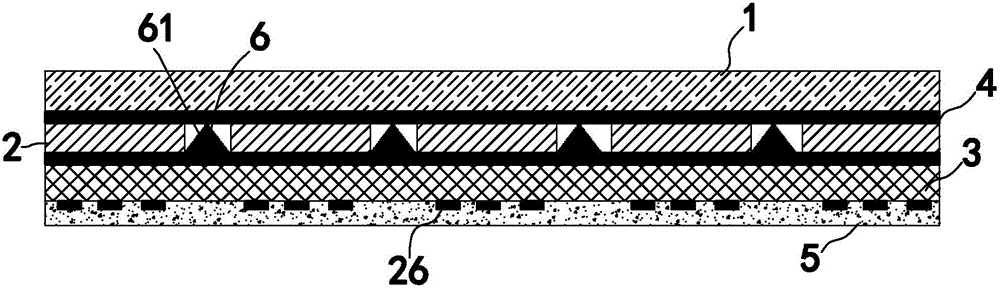

[0020] refer to figure 1 , this embodiment discloses a solar photovoltaic module, which includes a glass layer 1, several cells 2 arranged in a spaced array, and a photovoltaic backplane 3 from top to bottom, the glass layer 1, several cells 2 arranged in a spaced array, and a photovoltaic backplane 3 The backplanes 3 are bonded together by EVA adhesive film 4, the bottom surface of the photovoltaic backplane 1 is provided with a layer of reflective heat insulation layer 5, and the bottom is provided with a reflective heat insulation layer, so that part of the light that penetrates the battery sheet After being reflected by the reflective heat insulation layer at the bottom of the photovoltaic backplane, it is used again to improve the photoelectric conversion efficiency, thereby improving the power generation efficiency of the photovoltaic module. The phenomenon that overflows to the front of the specular reflection layer, forms partial occlusion, and affects the reflection o...

Embodiment 2

[0026]The structure of the solar photovoltaic module in this embodiment is the same as that of the previous embodiment, except that the reflective heat insulation layer includes the following raw materials in parts by weight: 25 parts by weight of organic silicon powder, 100 parts by weight of reflective powder, and 45 parts by weight of fluorescent powder , 25 parts by weight of acrylic acid powder, 20 parts by weight of modified phenolic resin, 40 parts by weight of borosilicate glass beads, 10 parts by weight of dispersant, 55 parts by weight of water, 200 parts by weight of pure acrylate elastic emulsion, 15 parts by weight of auxiliary materials .

[0027] The reflective powder is composed of the following raw materials by weight: 35 parts by weight of copper oxide powder, 40 parts by weight of silicon rubber, 100 parts by weight of titanium dioxide, 45 parts by weight of far-infrared ceramic powder, and 55 parts by weight of manganese dioxide.

[0028] The auxiliary mate...

Embodiment 3

[0029] Embodiment 3: The structure of the solar photovoltaic module in this embodiment is the same as that of the previous embodiment, except that the reflective heat insulation layer includes the following raw materials in parts by weight: 23 parts by weight of organic silicon powder, 95 parts by weight of reflective powder, fluorescent Powder 38 parts by weight, acrylic acid powder 22 parts by weight, polyvinyl alcohol phenolic modified phenolic resin 18 parts, borosilicate glass beads 38 parts by weight, dispersant 8 parts by weight, water 52 parts by weight, pure acrylate elastic emulsion 180 parts, 12 parts by weight of auxiliary materials.

[0030] The reflective powder is composed of the following raw materials in parts by weight: 28 parts by weight of copper oxide powder, 35 parts by weight of silicon rubber, 90 parts by weight of titanium dioxide, 40 parts by weight of far-infrared ceramic powder, and 42 parts by weight of manganese dioxide.

[0031] The auxiliary mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com