Multiphase magnetic integration coupling inductor

A coupled inductor and magnetic integration technology, applied in the field of inductors, can solve the problems of complex magnetic coupling structure of the iron core, large coil copper loss, and long coil length, etc., to improve efficiency and dynamic response speed, reduce copper loss, reduce Effect of Small Coil Length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

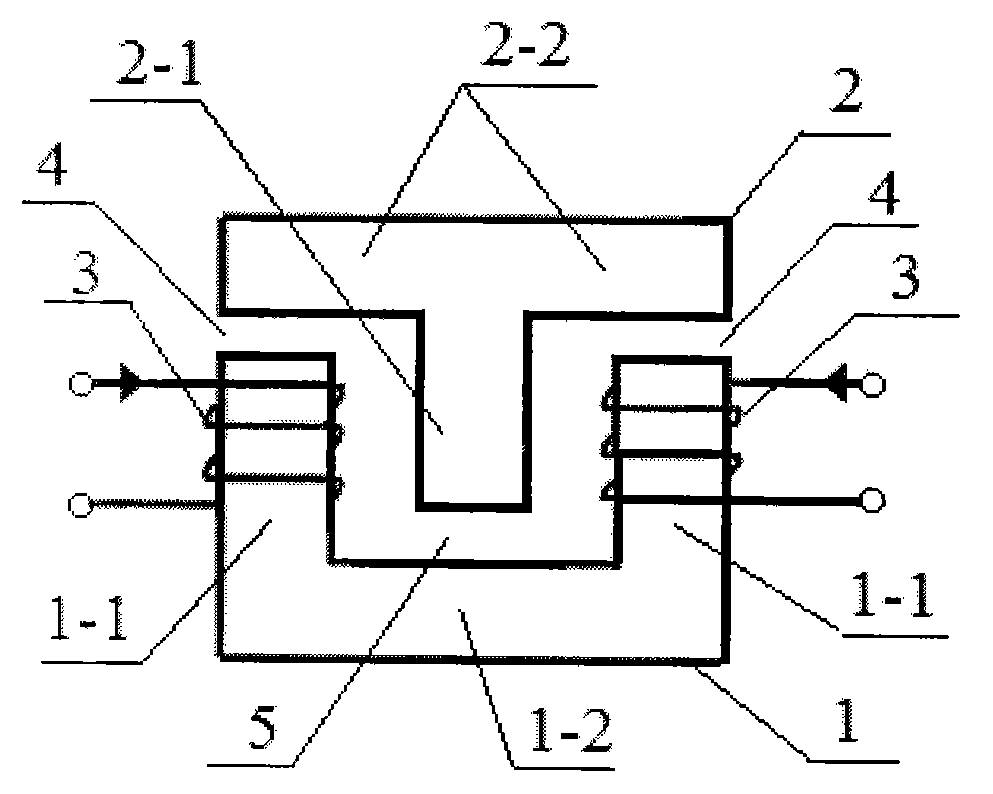

[0020] Refer to attached figure 1 , a two-phase magnetically integrated coupled inductor, composed of a "U"-shaped iron core 1, a "T"-shaped iron core 2 and a coil 3; the magnetic column 2-1 of the "T"-shaped iron core 2 is placed Between the two magnetic columns 1-1 of the "U"-shaped iron core 1; between the yoke 2-2 of the "T"-shaped iron core 2 and the two magnetic poles of the "U"-shaped iron core 1 A certain distance is kept between the pillars 1-1 to form two air gaps 4, between the magnetic yoke 1-2 of the "U" shaped iron core 1 and the magnetic pillar 2-1 of the "T" shaped iron core 2 A certain distance is kept between them to form an air gap 5; the two-phase coils 3 are respectively wound on the two magnetic columns 1-1 of the "U"-shaped iron core 1; the "U"-shaped iron core magnetic columns The cross section of 1-1 and "T" shaped iron core magnetic column 2-1 can be circular, semicircular, oval, triangular, rectangular, square, pentagonal, hexagonal, heptagonal, oct...

Embodiment 2

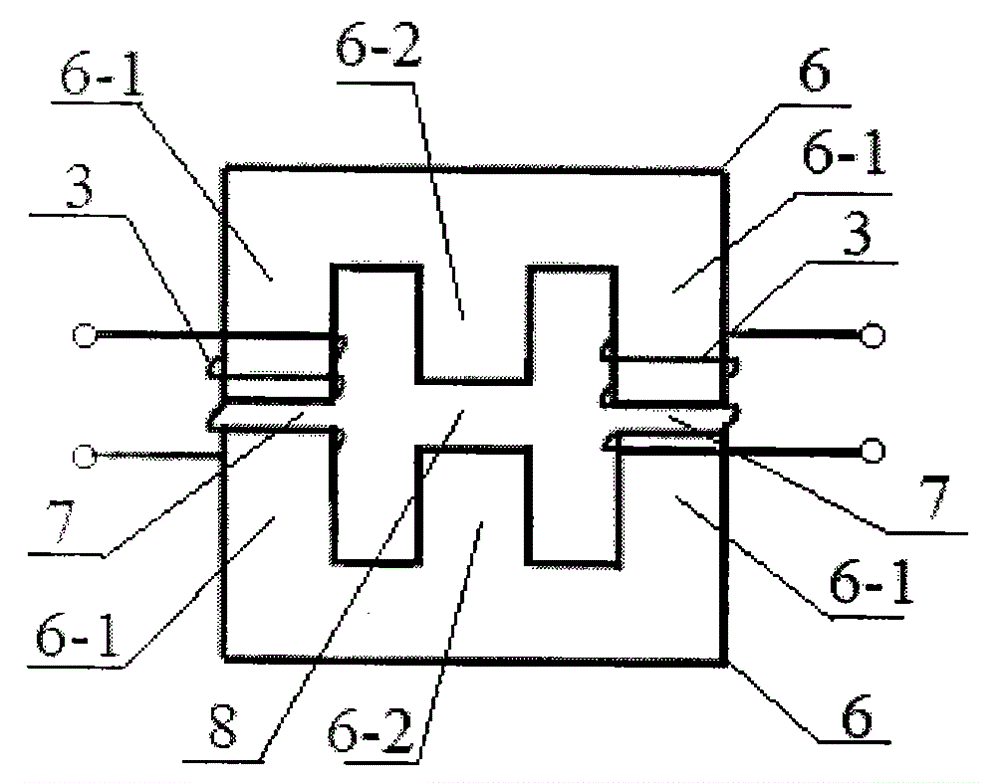

[0022] Refer to attached figure 2 , a two-phase magnetically integrated coupled inductor, an intermediate magnetic column is added between the two magnetic columns 1-1 of the "U"-shaped iron core 1 in Embodiment 1 to form an "E"-shaped iron core 6; Two outer magnetic columns are added at both ends of the yoke 2-2 of the "T"-shaped iron core 2 in Embodiment 1 to form another "E"-shaped iron core 6; in the two "E"-shaped iron cores A certain distance is maintained between the outer magnetic columns 6-1 of 6 to form an air gap 7, and a certain distance is maintained between the middle magnetic columns 6-2 of the two "E" shaped iron cores 6 to form an air gap 8, The two-phase coil 3 is wound on the outer magnetic columns 6 - 1 of the two "E" shaped iron cores 6 .

Embodiment 3

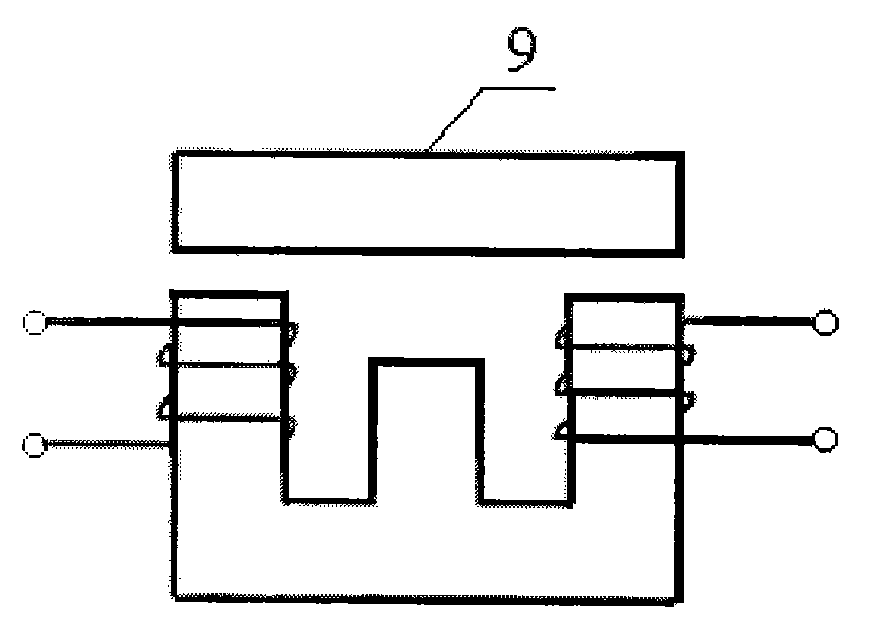

[0024] Refer to attached image 3 , a two-phase magnetically integrated coupled inductor, the three magnetic columns 6-1 and 6-2 of one of the "E"-shaped iron cores 6 in Embodiment 2 are removed to form an "I"-shaped iron core 9.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com