Manufacturing method of novel UV420 lens

A UV420, manufacturing method technology, applied in optical components, optics, instruments, etc., can solve problems such as high-energy blue-violet light blocking, and achieve the effects of easy control, reducing process chains, and preventing lens aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

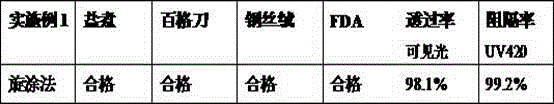

Embodiment 1

[0022] The technical scheme adopted in this embodiment is: a kind of manufacturing method of novel UV420 lens, and this technique comprises the following steps:

[0023] Step 1: Lens treatment: put CR-39, KOC 1.56, MR (1.60, 1.67, and 1.74) series resin lenses into the area to be hardened by category 2, and perform visual inspection on the lenses, clean them after pretreatment, and put them on the fixture;

[0024] Step 2: Solution preparation: add a UV absorber that can block the upper limit of 420nm in the hardening primer and top coating solution used by the dip coating hardening machine or in the hardening solution of the spin coating machine. The amount of the UV absorbent 1%, and fully stirred and mixed, and then added to the dipping and hardening machine with a 5μm filter element to circulate for 24 hours;

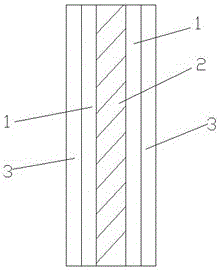

[0025] Step 3: Hardening and curing: The lens is hardened and cured by dip coating to form a hardened layer 1. After the lens is etched, cleaned and dried by ultras...

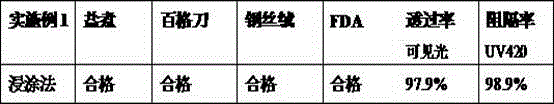

Embodiment 2

[0031] The technical scheme adopted in this embodiment is: a kind of manufacturing method of novel UV420 lens, and this technique comprises the following steps:

[0032] Step 1: Lens treatment: put CR-39, KOC 1.56, MR (1.60, 1.67, and 1.74) series resin lenses into the area to be hardened by category 2, and perform visual inspection on the lenses, clean them after pretreatment, and put them on the fixture;

[0033] Step 2: Solution preparation: add a UV absorber that can block the upper limit of 420nm in the hardening primer and top coating solution used by the dip coating hardening machine or in the hardening solution of the spin coating machine. The amount of the UV absorbent 1.2%, and fully stirred and mixed, and then added to the dipping and hardening machine with a 5μm filter element to circulate for 24 hours;

[0034] Step 3: Hardening and curing: The lens is hardened and cured by dip coating to form a hardened layer 1. After the lens is etched, cleaned and dried by ultr...

Embodiment 3

[0039] The technical scheme adopted in this embodiment is: a kind of manufacturing method of novel UV420 lens, and this technique comprises the following steps:

[0040] Step 1: Lens treatment: perform visual inspection and pretreatment on the resin mirror 2;

[0041] Step 2: Solution preparation: add a UV absorber that can block the upper limit of 420nm to the hardening solution used by the spin coater. 5μm filter cycle 2h;

[0042] Step 3: hardening and curing: the surface of the lens is hardened and cured by spin coating to form a hardening layer 1. After the lens is etched, cleaned and dried by ultrasonic KOH, the spin coating speed is adjusted to 400r / min , UV curing is adjusted to 2200r / min, and UV curing is 20s;

[0043] Step 4: Lens coating: After completing step 3, transfer the hardened and cured lens to Leybold vacuum coating machine to add coating layer 3;

[0044] Step 5: Inspection: The lens is tested according to the lens quality inspection ISO standard and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com