Double-slot type strengthened pipe type heat exchanger

A technology of strengthening tubes and heat exchangers, applied in the direction of heat exchanger types, heat exchanger shells, indirect heat exchangers, etc., can solve problems such as high energy consumption, low heat transfer efficiency, and unsatisfactory heat exchange effects, and achieve Effects of enlarging heat transfer surface, enhancing convective heat transfer, increasing shell-side fluid velocity and fluid heat transfer coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

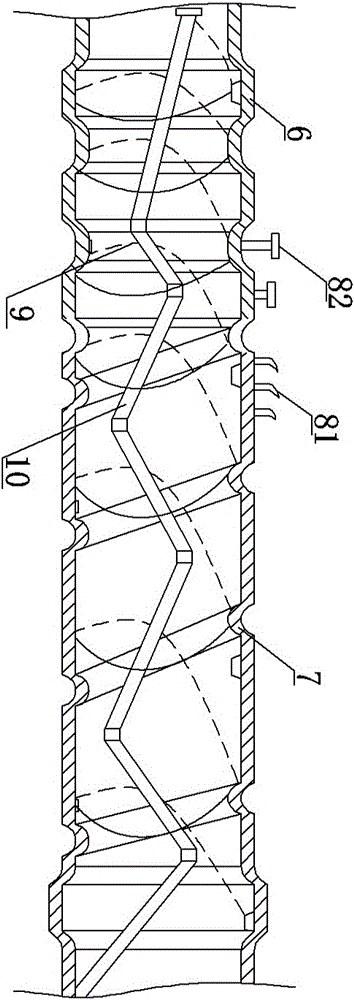

[0013] like figure 1 , figure 2 As shown, the present invention includes a shell 1, the two ends of the shell 1 are equipped with tube sheets, and the inner wall of the shell 1 between the tube sheets is provided with alternately arranged baffles, and the baffles are perpendicular to the length direction of the shell 1 , a number of heat exchange tubes 2 pass through the baffles, and are fixed on the tube plates at both ends in a square arrangement of corners. The baffles include an upper baffle 31, a lower baffle 32, an upper baffle 31, a lower baffle The baffles 32 are staggeredly arranged in the housing 1, one end of the upper baffle 31 is fixed on the upper wall of the housing 1, the other end of the upper baffle 31 forms a communication room with the lower wall of the housing 1, and the lower baffle One end of the plate 32 is fixed on the lower wall in the housing 1, and the other end of the lower baffle 32 forms a communication room with the inner upper wall of the hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com