Safe type phase change heat storage water tank

A phase-change heat storage and water tank technology, which is applied to heat storage heaters, fluid heaters, lighting and heating equipment, etc. The effect of preventing further temperature rise, reducing risk, and prolonging alert time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

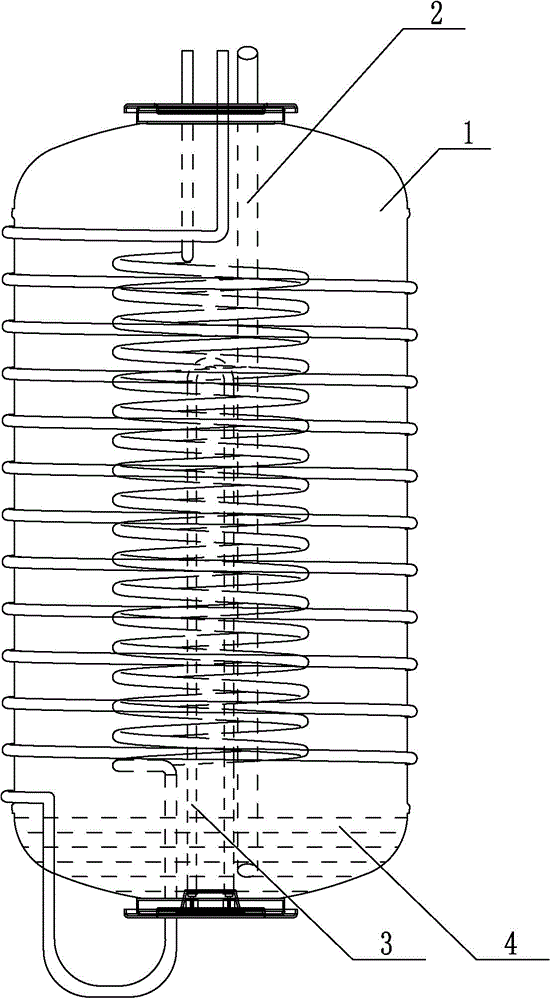

[0018] In this embodiment, an electric heating element is used as the heater 3, and the heat exchange inner coil and the heat exchange outer coil in series are used as the heat exchange coil. See figure 1 As shown, it includes a shell 1, a safety tube 2, an electric heating element, water, a phase change heat storage material, a heat conduction material, and a series of heat exchange inner coils and heat exchange outer coils. The shell 1 is composed of a cylinder body, a main cover and a sub cover. The safety pipe 2 is a hollow through pipe. The heat exchange inner coil is placed on the inside of the housing 1, and the two ports of the heat exchange inner coil are respectively extended out of the housing 1 through the main cover and the auxiliary cover; the heat exchange outer coil is placed on the outside of the housing 1 , The lower ports of the inner heat exchange coil and the outer heat exchange coil are connected to each other so that the inner heat exchange coil and the ...

Embodiment 2

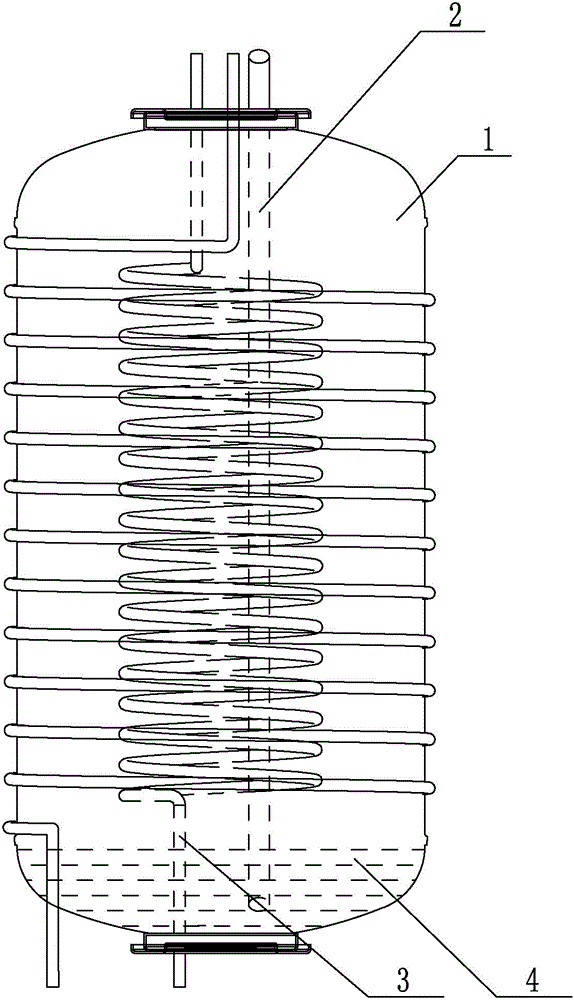

[0024] See figure 2 As shown, compared with the first embodiment, this embodiment eliminates the electric heating element, disconnects the inner coil and the outer coil in series, and resets the functions of the inner and outer coils. In this embodiment, the inner coil is used as the heater 3, and the outer coil is used as the heat exchange coil, and the other structure is the same as the first embodiment.

[0025] The heat storage process of this embodiment is: the heating inner coil is used as the heat storage fluid channel, the high temperature fluid enters the solid phase change heat storage material inside the heating inner coil heating shell 1, and then becomes a low temperature fluid and flows out, and the solid phase changes After the temperature of the heat storage material is higher than its phase change temperature, the phase change heat storage material is gradually liquefied into a liquid phase change heat storage material and stores a large amount of heat energy. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com