Built-in positioning prefabricated reinforced concrete shear wall and its construction method

A technology of reinforced concrete and construction method, applied in the direction of manufacturing tools, walls, building components, etc., can solve the problems of easy running and bulging of the formwork, poor positioning of steel bars, inaccurate thickness of the protective layer, etc. , the effect of rapid demoulding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below with reference to the accompanying drawings and examples. The following examples are explanations of the present invention and are not limited to the following examples.

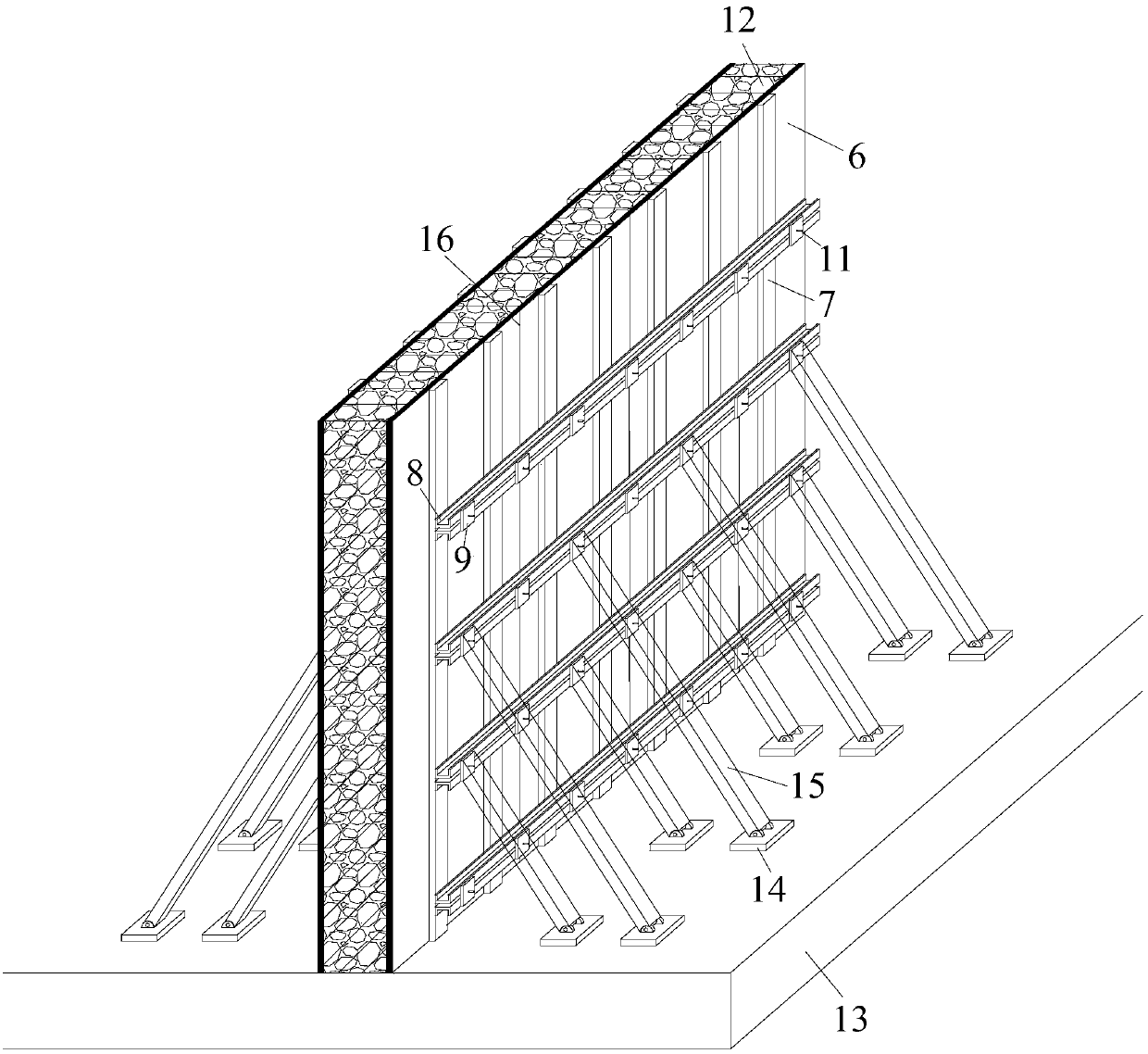

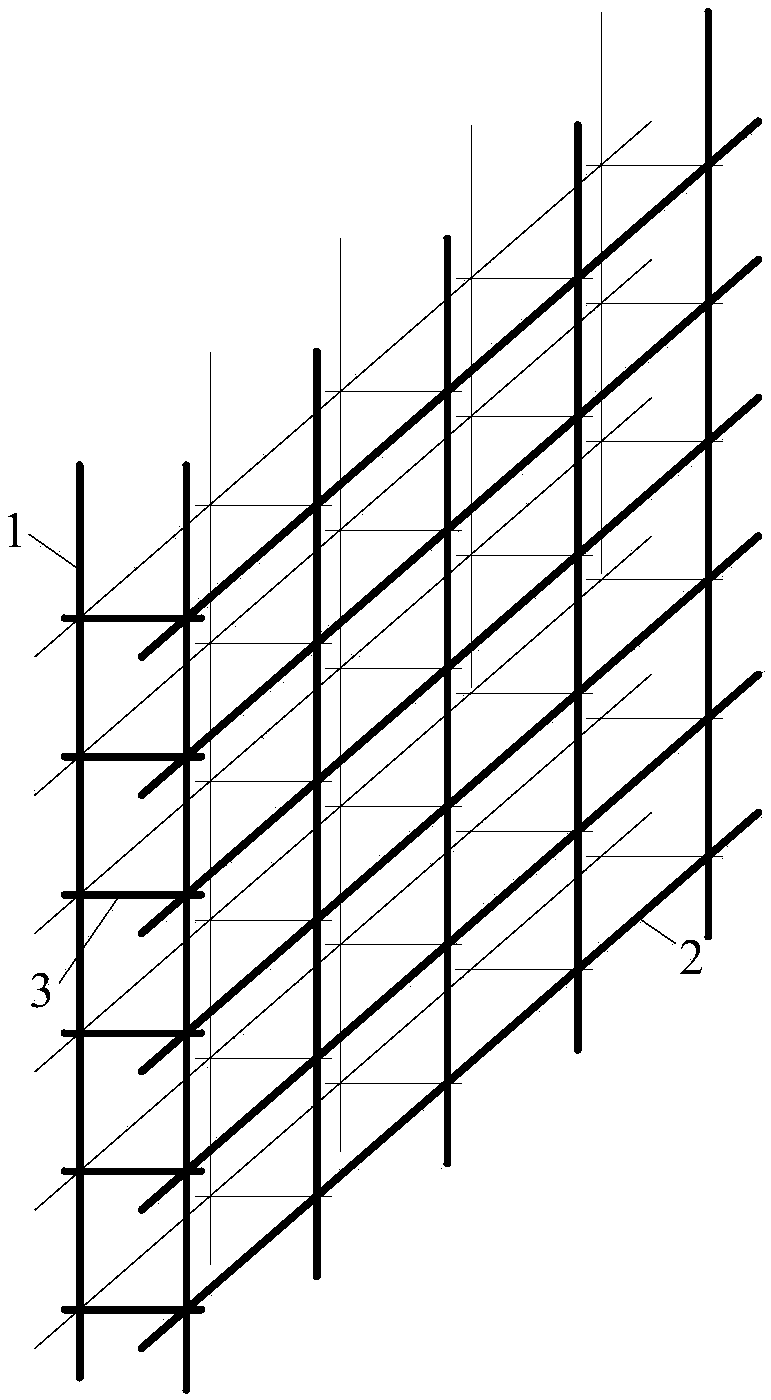

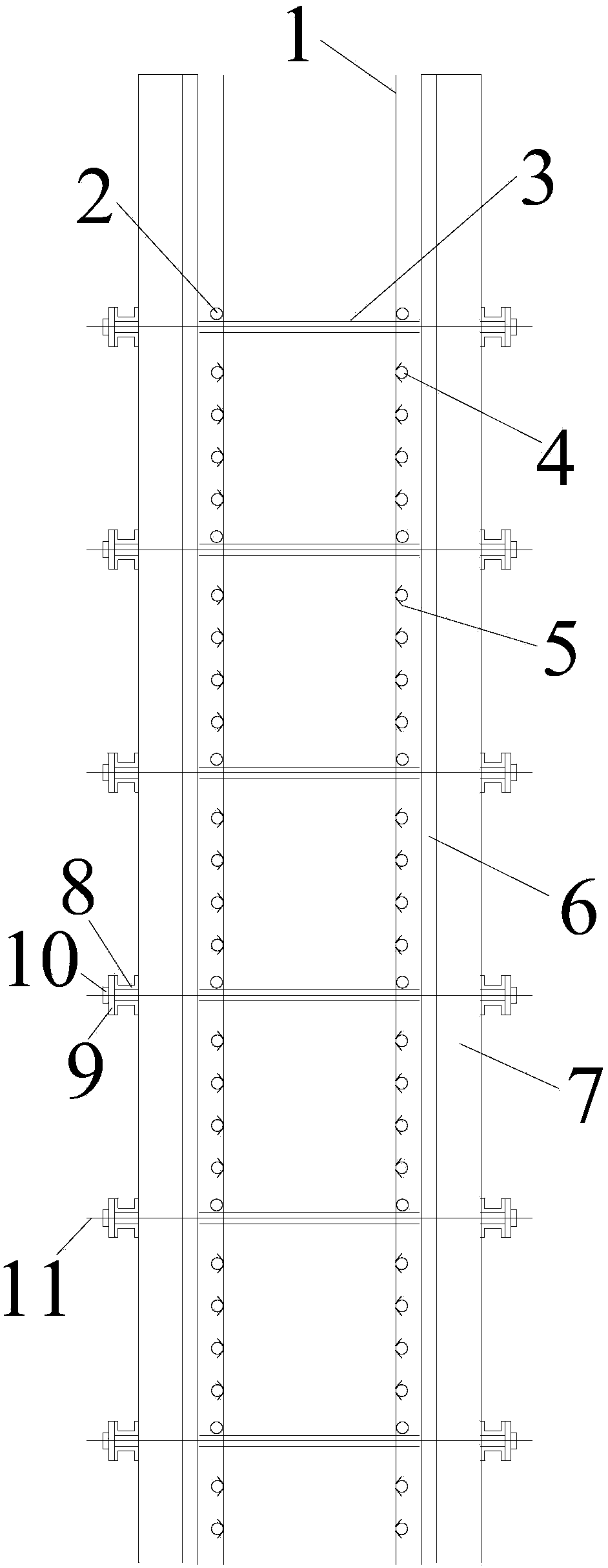

[0035] figure 1 It is the construction drawing of reinforced concrete shear wall formwork pouring concrete, figure 2 is a schematic diagram of the three-dimensional structure of the horizontal ladder bars and vertical ladder bars, image 3 is the positioning diagram of vertical ladder bars, Figure 4 It is a schematic diagram of the structure of the embedded parts of the floor slab, Figure 5 is a schematic diagram of the positioning prefab structure, Image 6 is the plan view of the positioning prefab mold, Figure 7 is the vertical section view of the positioning prefabricated part, refer to Figure 1-7 As shown, the construction process mainly includes the processing and production of prefabricated parts, the setting of embedded ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com