Groove external electroplating technology of cylinder body

An electroplating process and cylinder technology, applied in the direction of electrolytic coatings, coatings, etc., can solve the problems that the electroplating process cannot guarantee the quality of the composite coating, the cylinder products cannot meet the needs of use, and the quality assurance of the finished product is difficult, so as to avoid poor bonding force. , Guaranteed performance, high density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

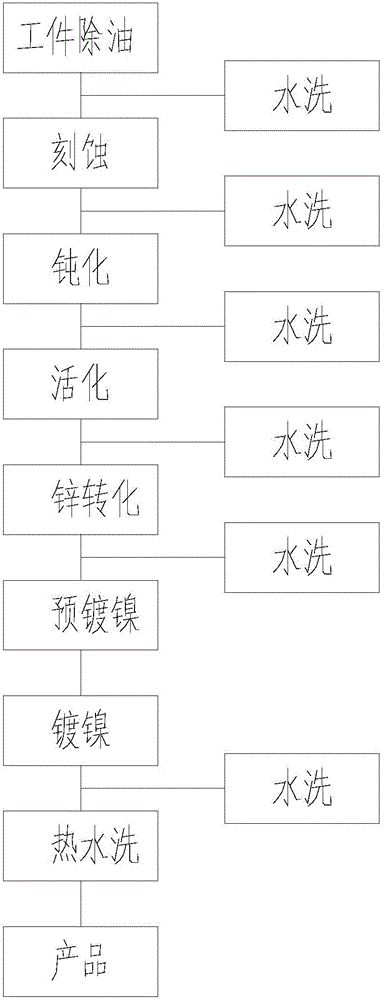

[0077] The electroplating process outside the tank of the cylinder body of the present embodiment comprises the following steps:

[0078] a. Preprocessing:

[0079] a1. Etching, through NaOH 25g / L lye alkali etching, the time is 175s, and the temperature of the alkali etching solution is 40°C; it is carried out by the way of lye flowing through the inner surface of the cylinder;

[0080]a2. Passivation, passivation is carried out by acid solution, which includes 50g / L of potassium hydrogen persulfate and 6g / L of sulfuric acid; the time is 175s, and the temperature of the acid etching solution is 35°C; the acid solution is used to flow through the cylinder superficially;

[0081] a3. Activation, further corroding the inner surface of the cylinder with hydrofluoric acid 13g / L acid solution; the time is 30s, and the temperature is room temperature; the acid solution flows through the inner surface of the cylinder;

[0082] a4. Zinc conversion, using chemical zinc conversion to ...

Embodiment 2

[0089] The electroplating process outside the tank of the cylinder body of the present embodiment comprises the following steps:

[0090] a. Preprocessing:

[0091] a1. Etching, through NaOH 5g / L lye alkali etching, the time is 180s, and the temperature of the alkali etching solution is 60°C; it is carried out by the way of lye flowing through the inner surface of the cylinder;

[0092] a2. Passivation, passivation is carried out by acid solution, which includes 12g / L of potassium hydrogen persulfate and 15g / L of sulfuric acid; the time is 180s, and the temperature of the acid etching solution is 45°C; the acid solution is used to flow through the cylinder superficially;

[0093] a3. Activation, further corroding the inner surface of the cylinder with hydrofluoric acid 4g / L acid solution; the time is 90s, and the temperature is room temperature; the acid solution flows through the inner surface of the cylinder;

[0094] a4. Zinc conversion, using chemical zinc conversion to ...

Embodiment 3

[0101] The electroplating process outside the tank of the cylinder body of the present embodiment comprises the following steps:

[0102] a. Preprocessing:

[0103] a1. Etching, through NaOH 18g / L lye alkali etching, the time is 178s, and the temperature of the alkali etching solution is 50°C; it is carried out by the way of lye flowing through the inner surface of the cylinder;

[0104] a2. Passivation, passivation is carried out by acid solution, which includes 35g / L of potassium hydrogen persulfate and 9g / L of sulfuric acid; the time is 178s, and the temperature of the acid etching solution is 40°C; the acid solution is used to flow through the cylinder superficially;

[0105] a3. Activation, further corroding the inner surface of the cylinder with hydrofluoric acid 8g / L acid solution; the time is 60s, and the temperature is room temperature; the acid solution flows through the inner surface of the cylinder;

[0106] a4. Zinc conversion, using chemical zinc conversion to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com