Totally-enclosed refractory flame-retardant flexible branch bus

A fire-resistant, flame-retardant, flexible busbar technology, applied in the direction of rod/rod/wire/strip conductor, rubber insulator, plastic/resin/wax insulator, etc., can solve the complicated manufacturing process, limited contact area and waste of metal at the shunt connection Material and other issues, to achieve the effect of improving stability and electrical conductivity, improving mechanical strength, and enhancing mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

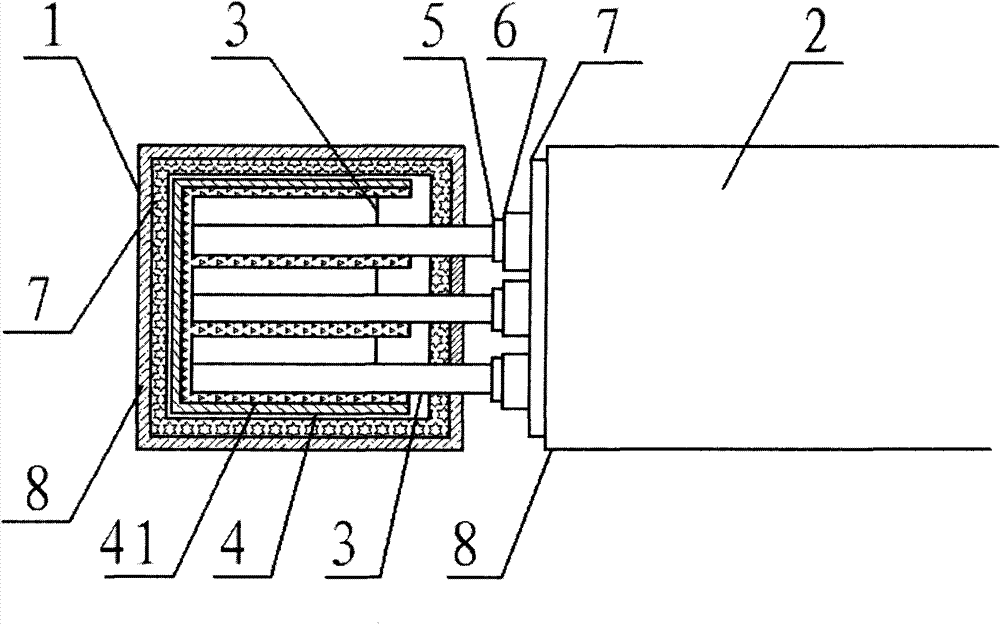

[0013] The technical solution of the present invention will be specifically described below in conjunction with the accompanying drawings.

[0014] Refer to attached figure 1 It is a cross-sectional schematic diagram of a fully enclosed fire-resistant and flame-retardant branch soft busbar. The branch busbar includes a main soft busbar 1 and a secondary soft Tightening clip 4 is connected and fixed together with the main soft busbar conductive strip that removes insulating layer and mica tape, between the fastening clip and the conductive strip and between the conductive strips that are connected to each other, there is an insulating partition 41 to separate, and the fastening clip is It is stamped and formed with high-quality steel plate to ensure the firm and stable connection of the conductive strip, and then the fastening clip and the connection between the main and auxiliary soft busbars are poured together with synthetic resin to ensure the airtightness of the busbar.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com