A simultaneous saccharification and fermentation process for cellulose-containing raw materials

A technology of simultaneous saccharification and fermentation, cellulose, applied in fermentation, biofuel and other directions, can solve the problems of low enzymatic hydrolysis efficiency of cellulose into ethanol, inability to achieve yeast/microorganism, unmatched fermentation temperature conditions, etc. Improve the efficiency of enzymolysis and fermentation, shorten the fermentation cycle, and shorten the effect of enzymolysis cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

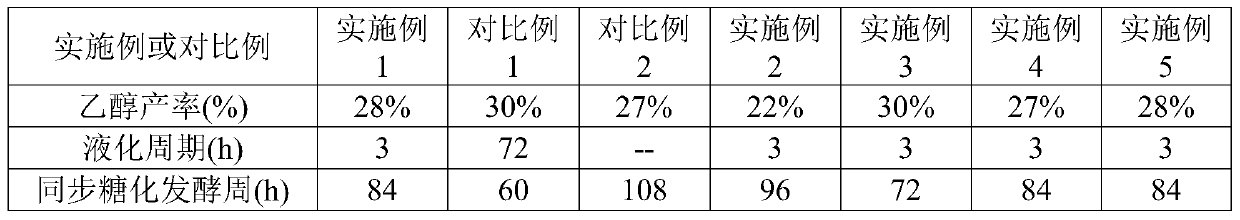

Embodiment 1

[0103] This example is used to illustrate the simultaneous saccharification and fermentation process of cellulose-containing raw materials of the present invention.

[0104] (1) Pretreatment of cellulose-containing raw materials

[0105] Cut 2,222 kg of impurity-free corn stalks (moisture content 10% by weight) into small sections not exceeding 1.2 cm x 0.5 cm x 1.0 cm, maintain a pressure of 1.0 MPa at 180°C for 5 minutes, and then release the pressure to complete steam explosion . A total of 4000 kg of steam explosion waste (water content 50% by weight) was obtained.

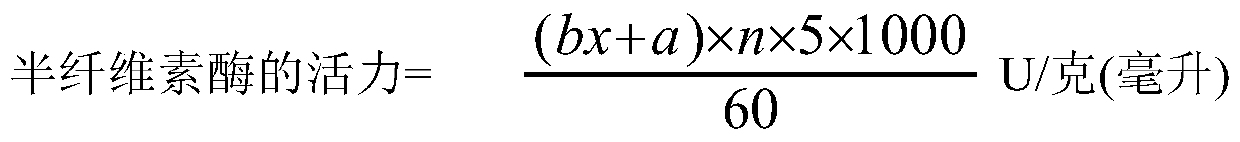

[0106] Determination of the total weight of cellulose and the total weight of hemicellulose in the resulting solid steam explosion product, see NREL / TP-510-42618 for details:

[0107]Take 10 grams of the above-mentioned steam explosion product and dry it at 45° C. to a constant weight of 5 grams, weigh 300.0 mg of the dried steam explosion product, and place it in a 100 ml sealable pressure-resistant glass t...

Embodiment 2

[0136] This example is used to illustrate the simultaneous saccharification and fermentation process of cellulose-containing raw materials of the present invention.

[0137] According to the method of Example 1, the cellulose-containing raw material was liquefied, and the liquefied product was subjected to simultaneous saccharification and fermentation, the difference was:

[0138] Before liquefaction, the pH value of the cellulose-containing raw material is adjusted to 4 with a sodium hydroxide solution having a pH regulator mass content of 40%.

[0139] In the liquefaction step (2), the temperature in the main enzymolysis device 2 is 40°C, and the added amount of the cellulose-containing raw material whose pH value has been adjusted is 320 kg / hour, expressed as the gram of fiber in the cellulose-containing raw material In terms of basic terms, the consumption of the cellulase is 10 enzyme activity units, and in the continuous liquefaction stage, the addition of the cellulase...

Embodiment 3

[0144] This example is used to illustrate the simultaneous saccharification and fermentation process of cellulose-containing raw materials of the present invention.

[0145] According to the method of Example 1, the cellulose-containing raw material was liquefied, and the liquefied product was subjected to simultaneous saccharification and fermentation, the difference was:

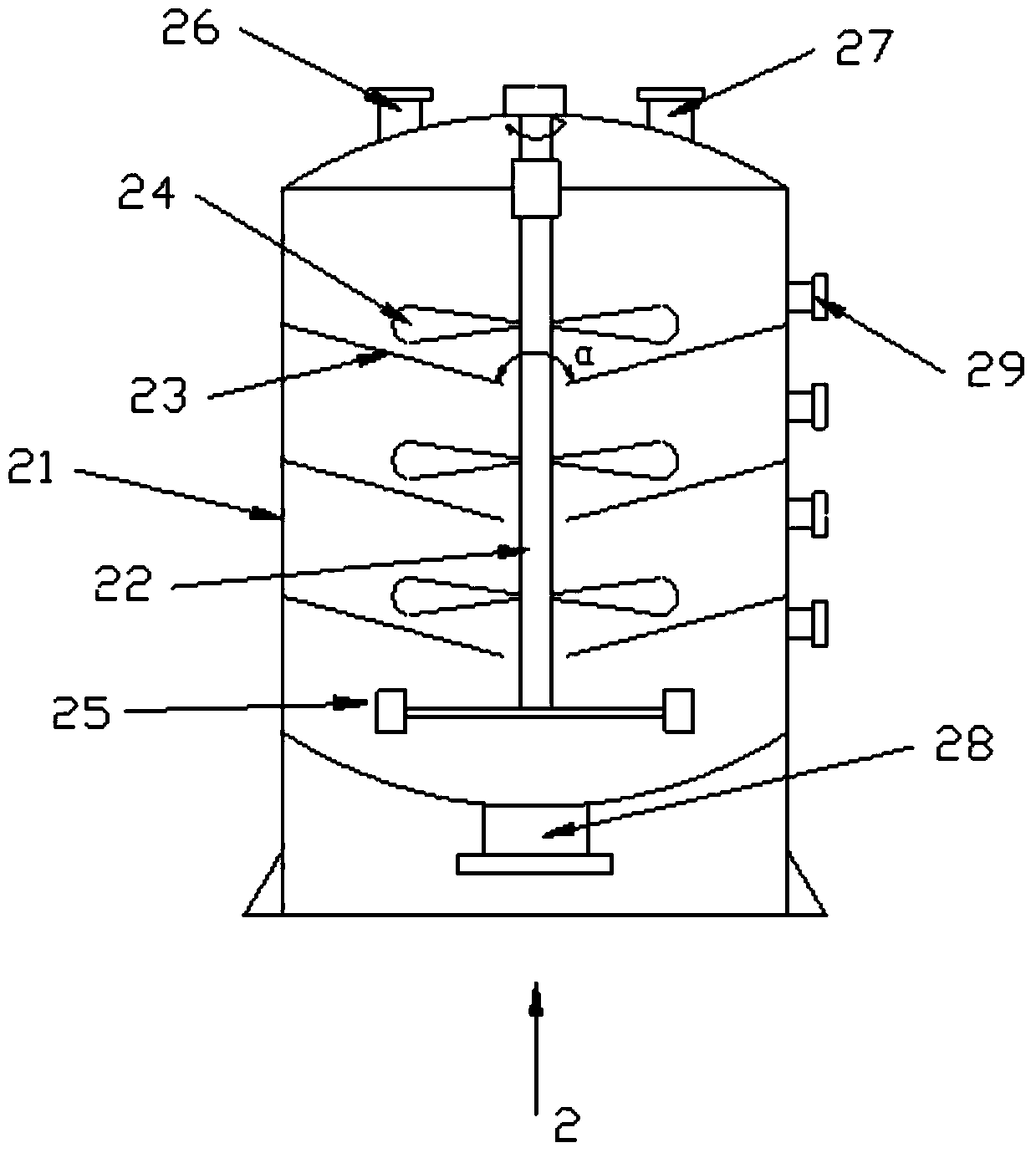

[0146] In the liquefaction step (2), cellulase and hemicellulase are continuously introduced into the tank body 21 from the enzyme inlet 27 at the top of the tank body 21 and the three supplementary enzyme inlets 29 at the side of the tank body 21, and are continuously introduced into the tank body 21 respectively. The amount of cellulase and hemicellulase added in the liquefaction space of the first layer, the second layer, the third layer and the fourth layer accounts for 30% and 30% of the total amount of cellulase and hemicellulase in the liquefaction stage respectively. 25%, 25%, and 20%. In the liqu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com