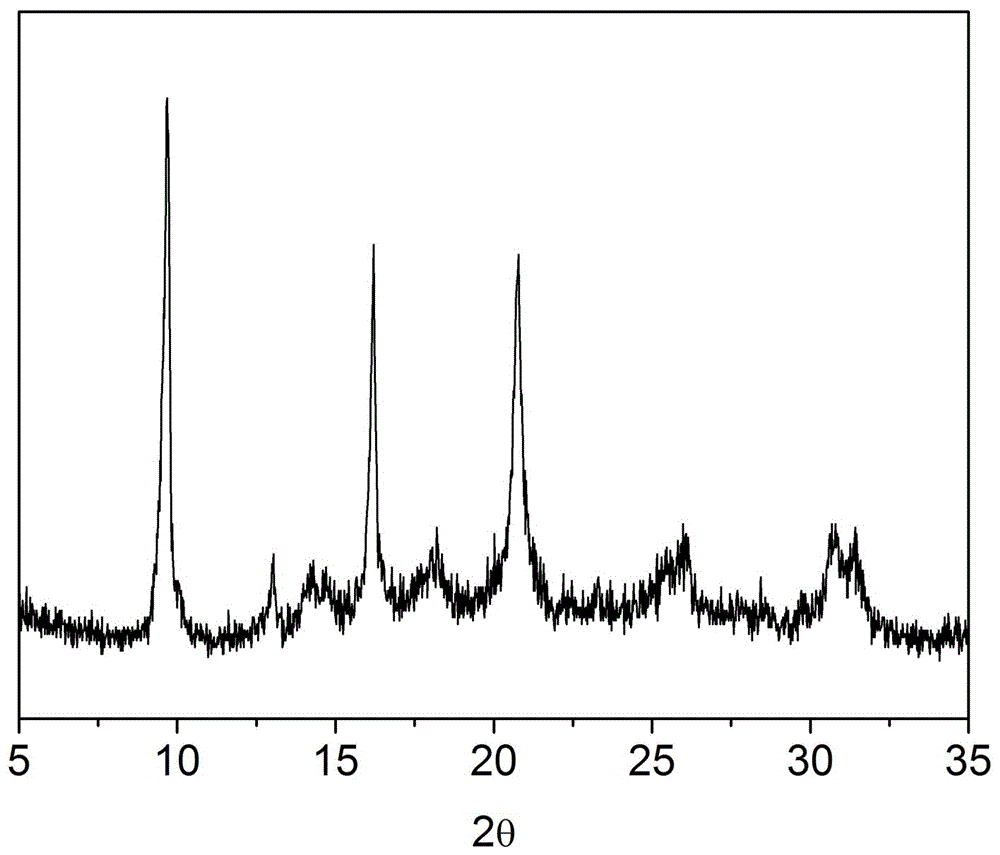

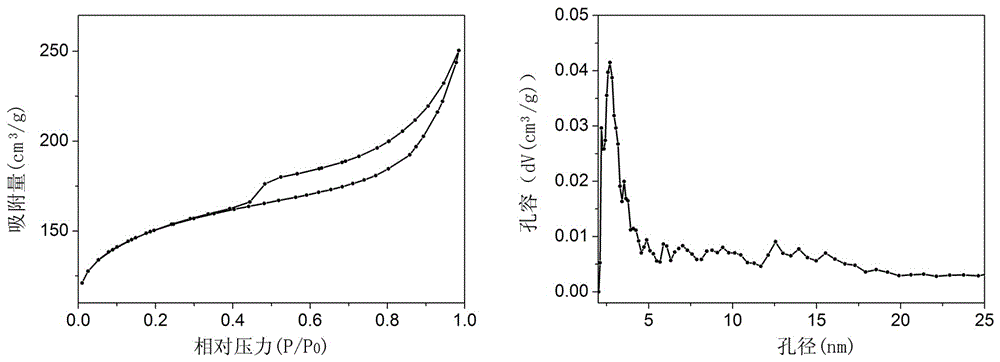

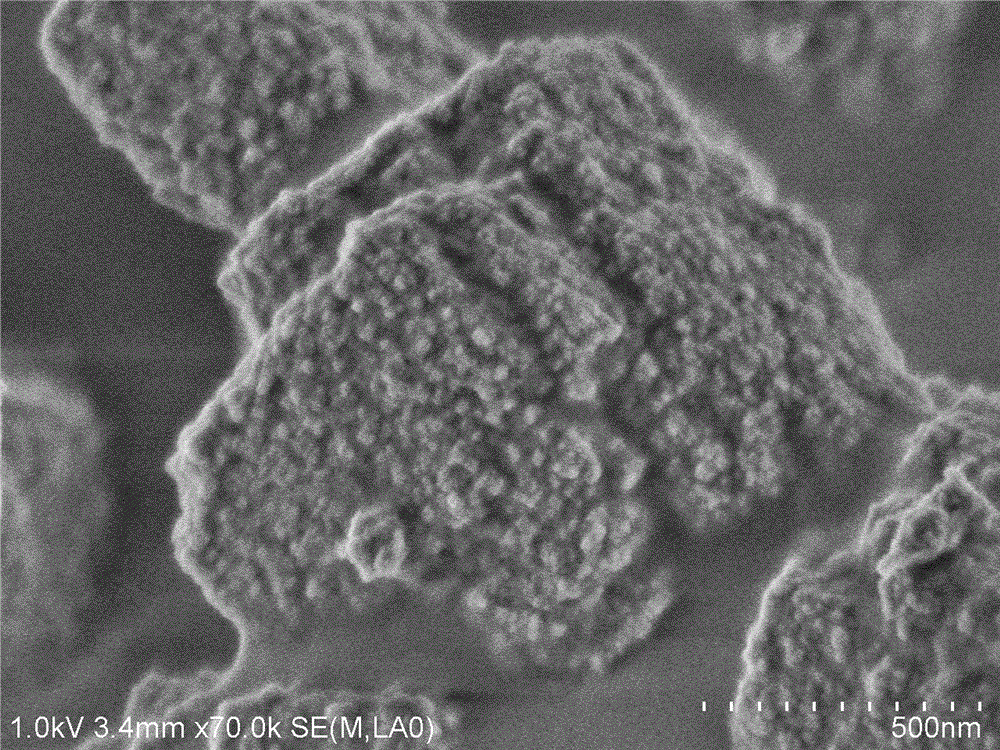

Preparation method of mesoporous SAPO-34 molecular sieve

A molecular sieve and solution technology, which is applied in the direction of molecular sieve and alkali exchange phosphate, molecular sieve characteristic silicoaluminophosphate, etc., can solve the problems of wide distribution, large pore size of multi-stage molecular sieve, difficulty in adjusting the ratio of silicon to aluminum, etc., and achieve improvement performance, overcoming the diffusion bottleneck, and the effect of low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Weigh 0.7g of PHAPTMS (density 1.07g / ml), mix it with 3ml of methanol and stir for 5min, slowly add 1ml of deionized water to make a solution; 2 / g gas phase SiO 2 After mixing with 10ml of deionized water and stirring for 5 minutes, it was added to the above solution, heated to 60° C. and stirred for 5 hours at a constant temperature to obtain a silicon source solution.

[0029] Add 20g of TEAOH aqueous solution with a mass concentration of 20% into a beaker, place it in a water bath at 60°C and stir it. After 5ml of water is evaporated, take it out at room temperature, add 2.44g of pseudo-boehmite, stir for 3 hours, and slowly add a mass concentration of 85 %H 3 PO 4 The solution was 2.38ml, stirred for 30 minutes, then added to the silicon source solution and stirred for 2-3 hours to obtain a gel.

[0030] Put the obtained gel into a reaction kettle lined with polytetrafluoroethylene, and conduct a hydrothermal crystallization reaction at 160°C for 10 days. ℃ cal...

Embodiment 2

[0037] Weigh 0.9g of PHAPTMS (density 1.07g / ml), mix it with 3ml of methanol and stir for 5min, slowly add 1ml of deionized water to make a solution; 2 / g gas phase SiO 2 After mixing with 10ml of deionized water and stirring for 5 minutes, it was added to the above solution, heated to 60° C. and stirred for 5 hours at a constant temperature to obtain a silicon source solution.

[0038] Add 23g of TEAOH aqueous solution with a mass concentration of 20% into a beaker, place it in a water bath at 60°C and stir it. After 8ml of water is evaporated, take it out at room temperature, add 2.44g of pseudo-boehmite, stir for 3 hours, and slowly add a mass concentration of 85 %H 3 PO 4 The solution was 2.38ml, stirred for 30 minutes, then added to the silicon source solution and stirred for 2-3 hours to obtain a gel.

[0039] Put the obtained gel into a reaction kettle lined with polytetrafluoroethylene, and conduct a hydrothermal crystallization reaction at 160°C for 10 days. ℃ cal...

Embodiment 3

[0042] Weigh 0.9g of PHAPTMS (density 1.07g / ml), mix it with 3ml of methanol and stir for 5min, slowly add 1ml of deionized water to make a solution; 2 / g gas phase SiO 2 After mixing with 10ml of deionized water and stirring for 5 minutes, it was added to the above solution, heated to 60° C. and stirred for 5 hours at a constant temperature to obtain a silicon source solution.

[0043] Add 20g of TEAOH aqueous solution with a mass concentration of 20% into a beaker, place it in a water bath at 60°C and stir, after evaporating 7ml of water, take it out at room temperature, add 2.44g of pseudo-boehmite, stir for 3 hours, and slowly dropwise add a mass concentration of 85 %H 3 PO 4 The solution was 2.38ml, stirred for 30 minutes, then added to the silicon source solution and stirred for 2-3 hours to obtain a gel.

[0044] Put the obtained gel into a reaction kettle with a polytetrafluoroethylene liner, and conduct a hydrothermal crystallization reaction at 180°C for 6 days. A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com