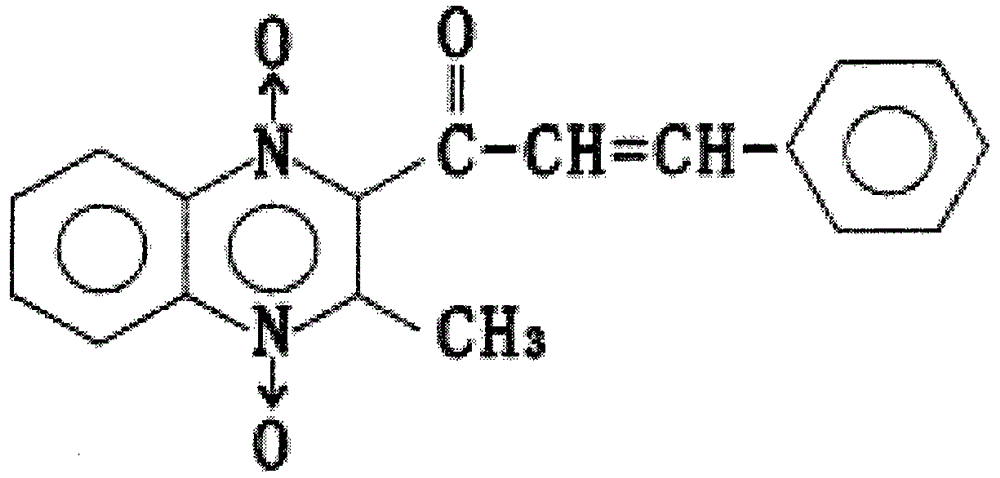

Water-soluble powder of cyclodextrin clathrate of quinocetone and preparation method thereof

A technology of quinocetone cyclodextrin and water-soluble powder, applied in the field of pharmaceutical preparations, can solve the problems of low bioavailability, poor absorption, poor dispersion and the like, and achieve the effects of high bioavailability, good solubility and improved water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] According to quinocetone:cyclodextrin:water=10:30~50:50~100 (mass percentage), weigh raw materials, adopt saturated aqueous solution method to prepare quinocetone clathrate, and its specific preparation steps are:

[0017] (1) Add 400g of β-cyclodextrin in proportion to the corresponding 1000g of water, stir and heat up;

[0018] (2) Continue to stir, heat up to about 80°C, add 100g of quinocetone, and make it mix evenly;

[0019] (3) Then control the temperature at about 80°C, continue stirring, and keep warm for 45 minutes;

[0020] (4) After the heat preservation is completed, the obtained material is poured into a baking tray and spread evenly, and put into an oven for continuous drying for 4 hours at a drying temperature of 95-105° C. to obtain a powdery quinocetone clathrate;

[0021] (5) cooling, crossing 60 mesh sieves with the cooled powdered quinocetone cyclodextrin inclusion compound;

[0022] (6) Sampling of the inclusion compound of quinone cyclodextrin t...

Embodiment 2

[0024] According to quinocetone:cyclodextrin:water=10:30~50:50~100 (mass percentage), weigh raw materials, adopt saturated aqueous solution method to prepare quinocetone clathrate, and its specific preparation steps are:

[0025] (1) Add 320g of α-cyclodextrin in proportion to the corresponding 800g of water, stir and heat up;

[0026] (2) Continue to stir, heat up to about 65°C, add 100g of quinocetone, and make it mix evenly;

[0027] (3) Then control the temperature to about 65°C, continue stirring, and keep warm for 60 minutes;

[0028] (4) After the heat preservation is completed, pour the obtained material into a baking tray and spread it evenly, put it in an oven for continuous drying for 3 hours, and the drying temperature is 90-100° C. to obtain a powdery quinocetone clathrate;

[0029] (5) cooling, crossing 60 mesh sieves with the cooled powdered quinocetone cyclodextrin inclusion compound;

[0030] (6) Sampling of the inclusion compound of quinone cyclodextrin to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com