Automatic production process of chargers

A production process and charger technology, applied in the field of automatic charger production process, can solve the problems of high cost, difficult automatic production line, unreasonable process arrangement, etc., and achieve the effect of improving processing efficiency, reducing damage and reliable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

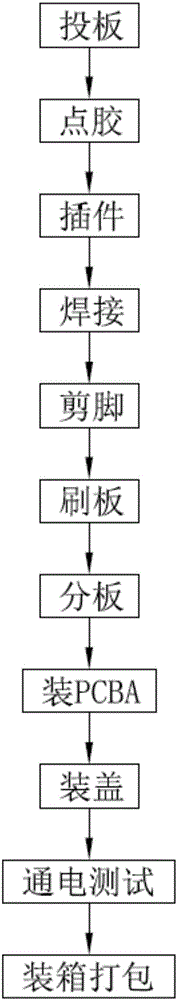

[0034] Such as figure 1 As shown, an embodiment one of an automatic production process for a charger includes the following process steps:

[0035] 1) Casting boards, using turnover boxes to transport PCB boards to the production line one by one;

[0036] 2) Dispensing, use the automatic dispensing machine to process the PCB board on the production line;

[0037] 3) Plug-in, use the automatic plug-in machine to insert and process electronic components on the PCB board on the production line;

[0038] 4) Soldering, using wave soldering equipment to solder and fix the electronic components on the PCB;

[0039] 5) Cutting the feet, shortening the electronic components that are too long on the soldered electronic components;

[0040] 6) Brush the board, use the automatic brush board equipment to clean the tin beads, rosin and / or dust remaining on the PCB board;

[0041] 7) Divide the board, use automatic board division equipment to cut and separate the PCB boards connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com