Groove type CoolMOS and manufacturing method thereof

A manufacturing method and trench-type technology, which are applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of reducing process steps, complex CoolMOS manufacturing process, and reducing chip area, so as to reduce chip area and manufacturing Steps to improve the effect of pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

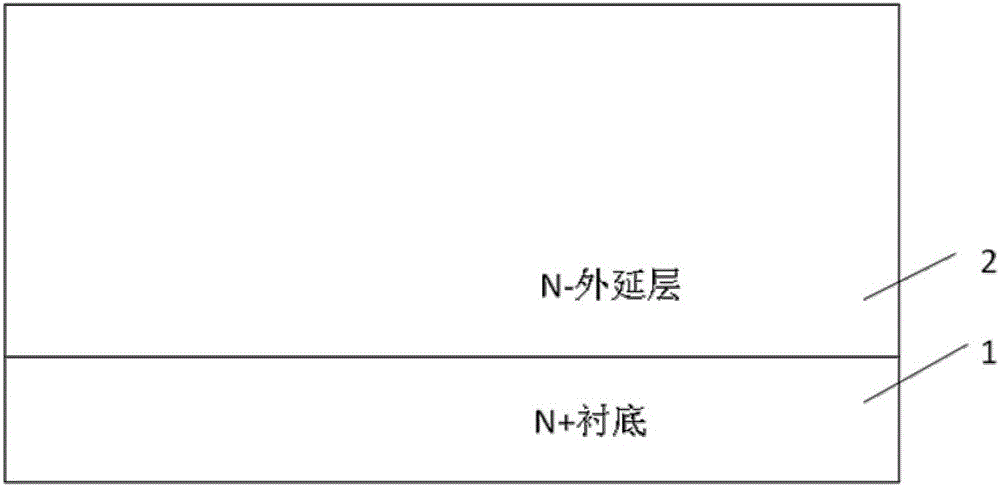

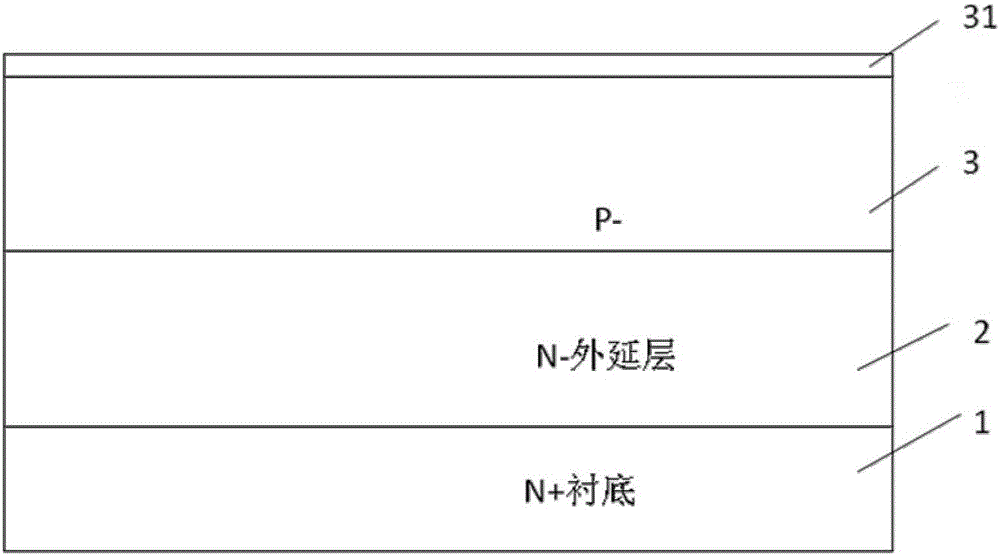

[0031] Such as Figure 12 As shown, a trench-type CoolMOS, from bottom to top includes back metal layer 13, N+ substrate 1, N- epitaxial layer 2, P- well region 3, n+ source region 7, insulating layer 8 and front metal layer 10;

[0032] The N+ substrate 1 is provided with several super junction trenches 11 penetrating through the N+ substrate 1, one end of the super junction trenches 11 extends to the N- epitaxial layer 2, and the inside of the super junction trenches 11 Filled with P-type silicon 12;

[0033] The P-well region 3 is provided with some gate grooves 4 (gate grooves 4 separate the P-well region 3 from each other, and the n+ source region 7 passes through the P-well region 3 and the n+ source region 7). located between the gate trenches 4), one end of the gate trenches 4 extends to the N- epitaxial layer 2, the gate trenches 4 are filled with polysilicon 6, the polysilicon 6 and the gate trenches 4 The vertical distance between the gate trench 4 and the super ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com