Liquid crystal display panel, manufacturing method thereof and display

A technology for liquid crystal panels and substrates, which is applied in the fields of instruments, nonlinear optics, optics, etc., can solve the problems of high production cost and complex process, and achieve the effect of improving quality, simplifying process, saving material cost and manufacturing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

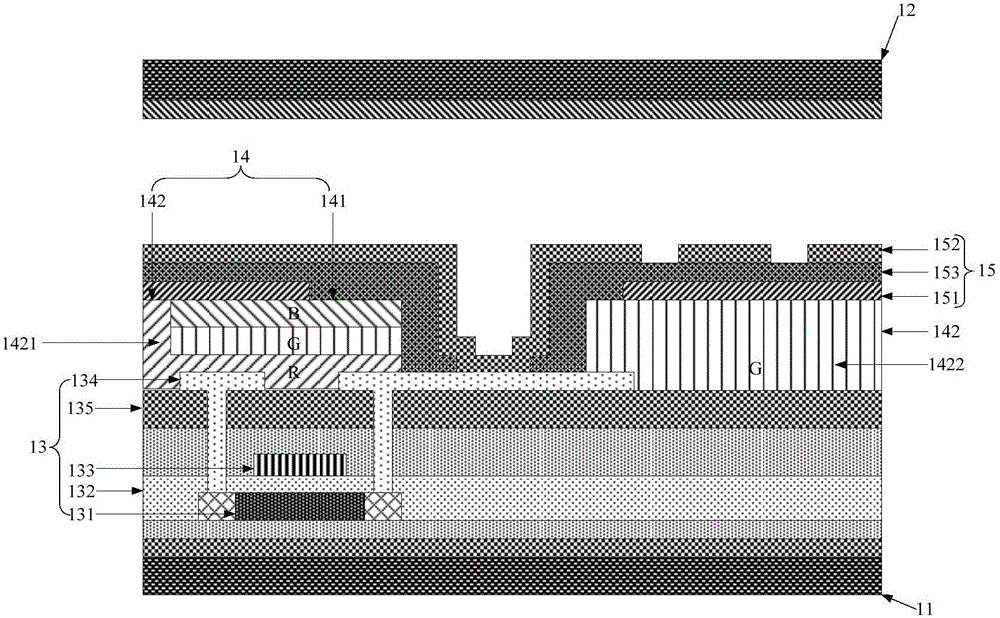

[0033] see figure 2 , figure 2 It is a structural schematic diagram of the first embodiment of the liquid crystal panel of the present invention.

[0034] The liquid crystal panel of the present invention includes a first substrate 11 , a second substrate 12 and a liquid crystal layer (not shown) between the first substrate 11 and the second substrate 12 .

[0035] A TFT array layer 13 , a color resist layer 14 and an electrode structure layer 15 are sequentially provided on the first substrate 11 .

[0036] The color resist layer 14 is formed by various color resists, the color resist layer includes a light-shielding area 141 and a plurality of pixel areas 142, the light-shielding area 141 is in a matrix shape, the plurality of pixel areas 142 are separated by the light-shielding area 141, and each pixel area 142 includes a different ki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com