Method for detecting phthalic acid ester plasticizer in plastics

A technology of phthalic acid and ester plasticizers, which is applied in the direction of measuring devices, analyzing materials, and material analysis through electromagnetic means, can solve the problems of inaccurate quantitative detection results, and achieve simple pretreatment methods and short detection times. Short, high-resolution effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

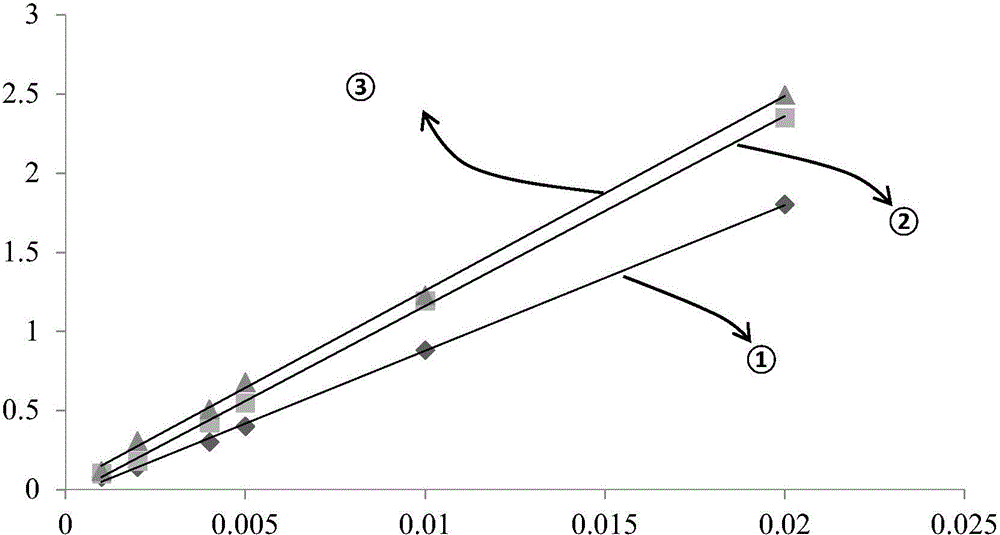

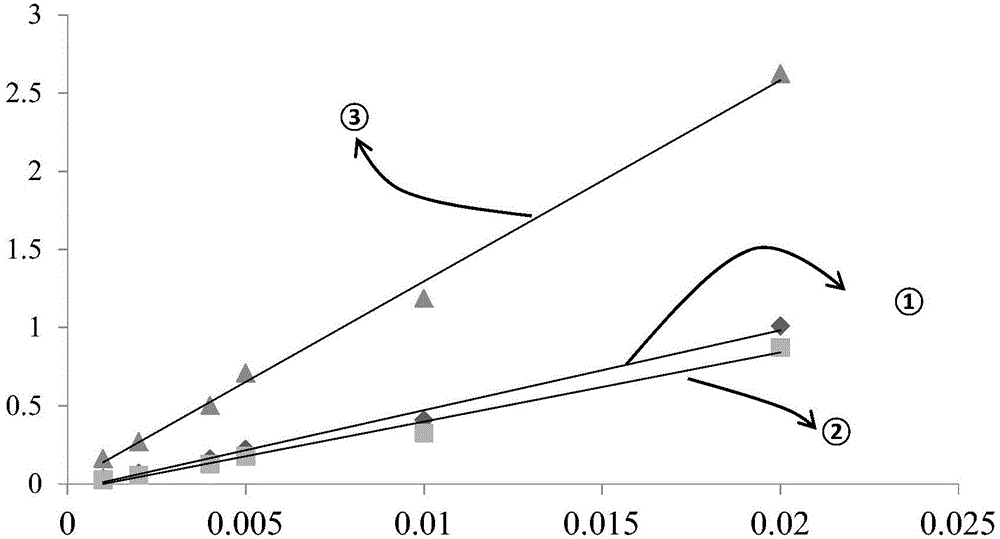

[0046] Preparation of standard curve

[0047] (1) Preparation of standard sample solution (solvent is tetrahydrofuran):

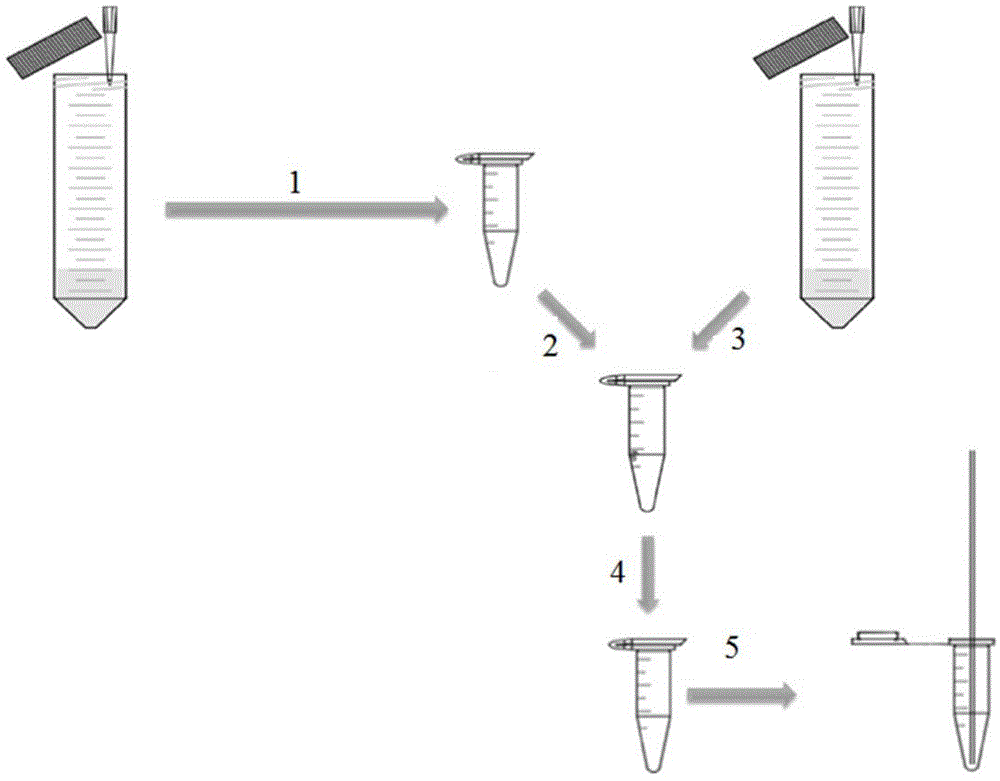

[0048] The preparation diagram is as follows figure 1 Shown:

[0049] Step 1: Take plasticizer standard solution (tetrahydrofuran solution of plasticizer, the concentration is 0.01mg / mL or 0.1mg / mL respectively);

[0050] Step 2: Evaporate to dryness;

[0051] Step 3: Add PVC standard solution (THF solution of PVC, the concentration is 1mg / mL);

[0052] Step 4: Mix evenly, be mixed with standard sample solution (solution S); The concentration of standard sample solution and the amount of each standard solution are as shown in Table 2;

[0053] Step 5: Dip the quantitative solution S for detection;

[0054] Among them, the plasticizers were BMPP, BBP, DEHP and DINP; standard curves were prepared with these four plasticizers.

[0055] Table 2 Concentration of standard sample solution and the amount of each standard solution

[0056]

[0057]

[005...

Embodiment 2

[0093] Quantitative detection of plasticizers in PVC plastic products

[0094] (1) Pretreatment of PVC: Grind PVC, dissolve it in tetrahydrofuran, and prepare a test sample solution with a concentration of 0.001 mg / mL;

[0095] (2) mass spectrometry detection, detection conditions such as embodiment 1;

[0096] (3) According to the standard curve of embodiment 1, calculate the content of plasticizer in the PVC.

[0097] The test results of this embodiment are the same as those of Embodiment 1, the repeatability and stability are good, and the result reliability is high.

Embodiment 3

[0099] The sample injection method in this embodiment is direct solid injection of plastics with a particle size of less than 1 mm, and the other conditions are the same as those in Examples 1 and 2 of the present invention.

[0100] The test results of this embodiment are the same as those of Embodiment 1, the repeatability and stability are good, and the result reliability is high.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com