Efficient drying device

A drying device and high-efficiency technology, applied in the directions of drying, drying machine, drying gas arrangement, etc., can solve the problems of difficulty in popularization and application, high investment cost, long drying time, etc., achieving good drying effect and preventing Leakage and electric shock accidents, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

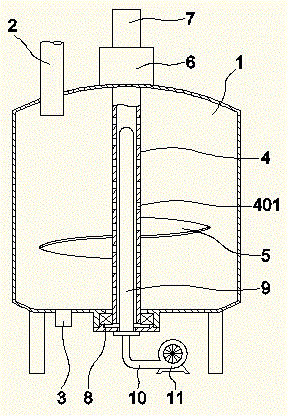

[0014] like figure 1 As shown, a high-efficiency drying device of the present invention includes a tank body 1, the top of the tank body 1 is provided with a feed port 2, the bottom of the tank body 1 is provided with a discharge port 3, and the tank body 1 There is a stirring shaft 4 inside, and the stirring shaft 4 is provided with a spiral stirring blade 5, and the upper end of the stirring shaft 4 is connected to a reducer 6 arranged on the outer top of the tank body 1, and the reducer 6 is connected to the drive Motor 7, the stirring shaft 4 is a hollow structure, the side wall of the stirring shaft 4 is processed with a plurality of through holes 401, the lower end of the stirring shaft 4 is installed in the bearing 8 at the bottom of the tank body 1; the stirring shaft 4 is provided with an electric heating pipe 9, and the stirring shaft 4 communicates with a fan 11 through a ventilation pipe 10.

[0015] The inside of the electric heating tube 9 is provided with an el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com