Device and method for heating and melting rubbish under oxygen-rich condition

A garbage and conditional technology, applied in the direction of combustion method, lighting and heating equipment, indirect carbon dioxide emission reduction, etc., can solve the problems that it is difficult to ensure gasification and melting reaction oxygen, reduce energy utilization rate, reduce oxygen utilization rate, etc., and achieve significant Economic and environmental benefits, reduced usage, and reduced exhaust heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

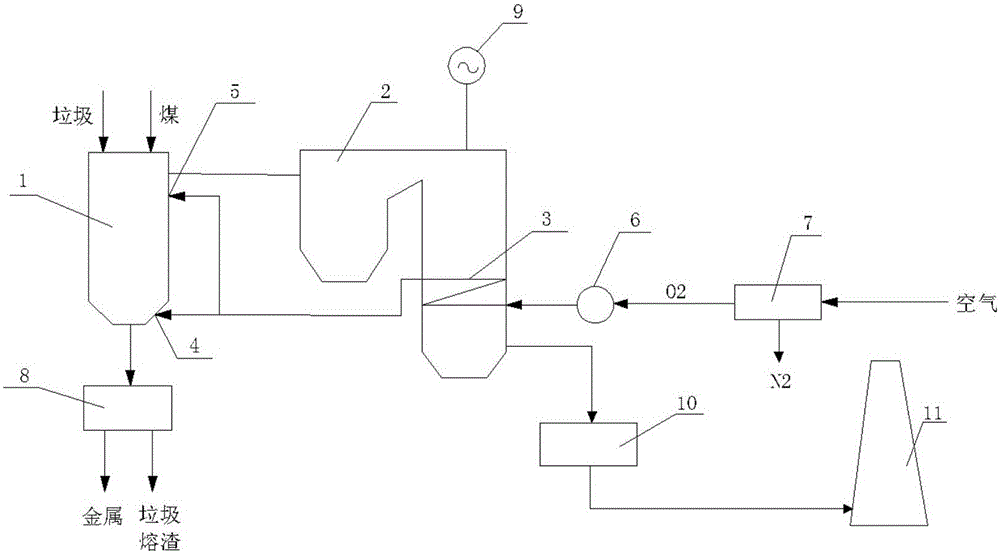

[0034] Such as figure 1As shown, a device for heating and melting garbage under oxygen-enriched conditions includes a garbage melting furnace 1, a waste heat boiler 2, an air preheater 3, a melting furnace bottom blowing port 4, a melting furnace top blowing port 5, a blower 6, and an air separation Device 7, water cooling pool 8, power generation device 9, flue gas treatment device 10 and chimney 11. Garbage melting furnace 1 top is provided with garbage inlet and auxiliary fuel inlet, and the bottom of garbage melting furnace 1 is connected with water cooling pool 8, and water cooling pool 8 has a metal outlet and garbage slag outlet. There are blowing ports 5 on the top of the melting furnace and blowing ports 4 on the bottom of the melting furnace; the air is separated from the oxygen by the air separation device 7, and the oxygen is sent to the ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com