Medium-thickness gentle-dip broken ore body and chamber column type upward horizontal layering filling mining method

A filling mining method and a gentle inclination technology, which is applied in the direction of filling, ground mining, mining equipment, etc., can solve the problems of poor mining effect of gently inclined and broken ore bodies, and achieve the effect of low ore dilution and safe mining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

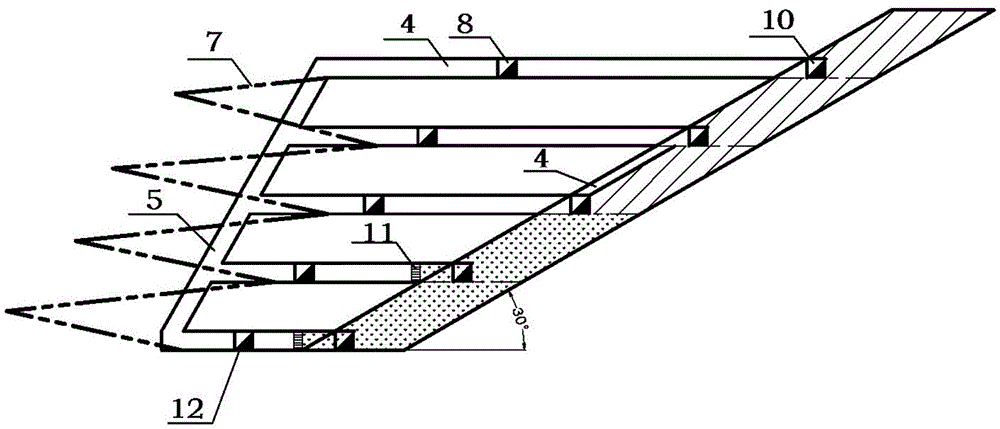

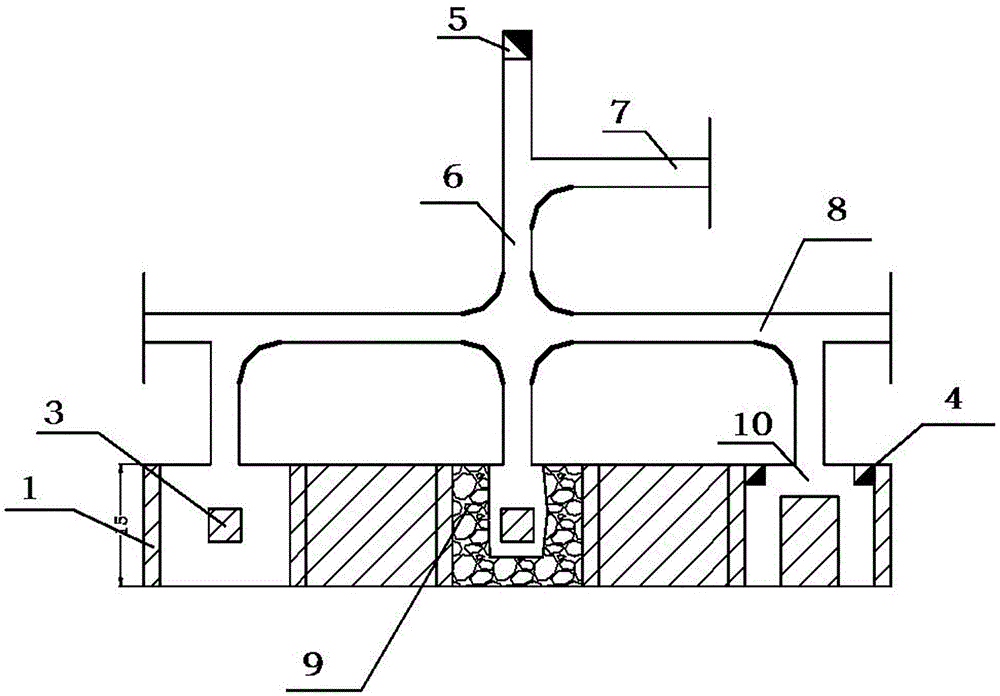

[0022] see Figure 1-3 , the medium-thick gently inclined broken ore body is upward horizontal layered filling mining method, and the mining method is carried out according to the following steps:

[0023] (a) First, a ramp 7 is arranged on the upper wall of the ore body, and the ramp 7 is connected to the ore crossing 6 of each subsection, and the ramp 7 is the walking passage for scrapers and personnel;

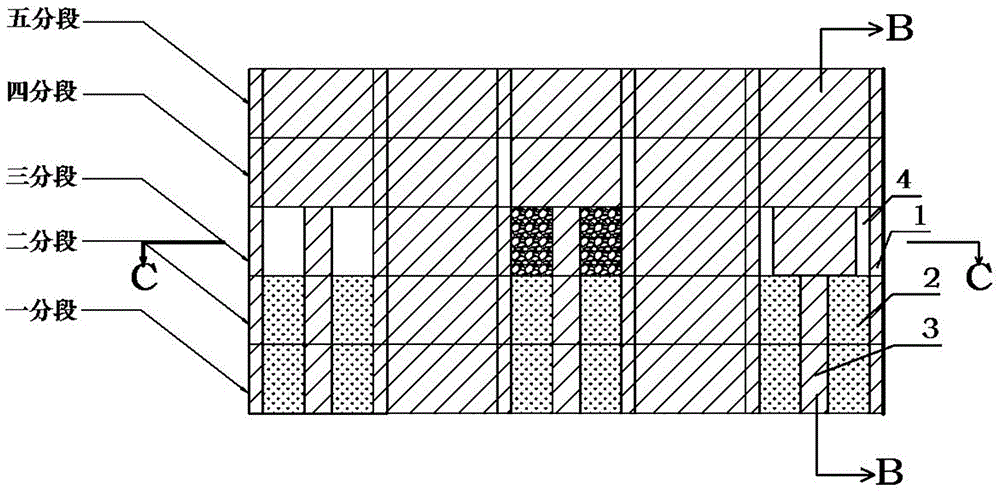

[0024] (b) Divide each stope into five subsections, which are the first section, the second section, the third section, the fourth section and the fifth section, and each section is connected by a ramp 7;

[0025] (c) Arrange the layered level roadway 10 on the roof of the hanging ore body inside the stope of each sub-section, as the scraper channel for ore discharge in the vein, and arrange the sub-sections outside the upper wall of the second sub-section to the fifth sub-section. Sectional transport level road 8, sectional transport level road 8 is parallel to the strike...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com