All-steel structure building and construction method thereof

A technology for building construction and steel structure, applied in the direction of infrastructure engineering, construction, underwater structures, etc., can solve the problems of large installation constraints of engineering steel components, high installation accuracy requirements, and simultaneous entry of components to ensure installation. High precision, high structural strength, ensuring the effect of installation progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

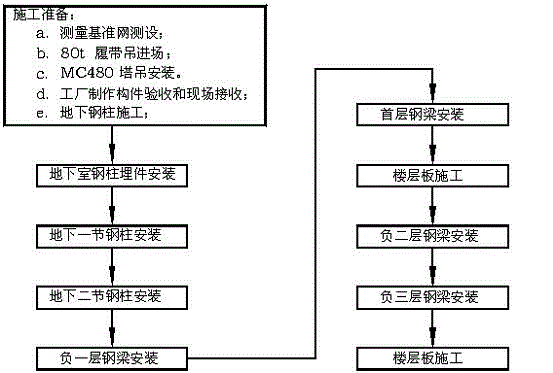

[0032] Below in conjunction with accompanying drawing, further illustrate the present invention.

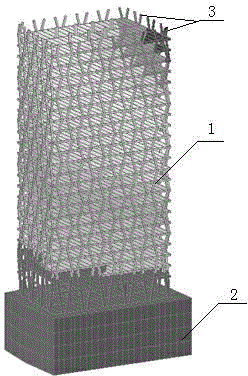

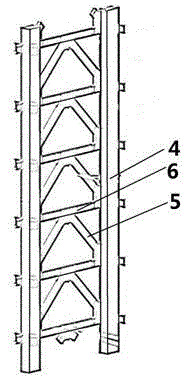

[0033] Such as Figures 1 to 3 As shown, the all-steel structure building, the steel structure components are all made of low-alloy high-strength steel Q345B, which is composed of the above-ground all-steel structure 1 and the underground all-steel structure 2; the above-ground all-steel structure 1 includes the all-steel structure outer frame 3, core columns 4. The support 5 and the steel beam 6 are composed; the core column 4 is connected with the steel beam 6 and one end of the support 5 respectively, the middle of each steel beam 6 is respectively connected with one end of the two supports 5, and the other end of the support 5 is connected with the core The cylinder column 4 forms the axial plane structure of the core cylinder. The other three surfaces of the core cylinder column 4 are connected with the same axial plane structure of the core cylinder to form the core cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com