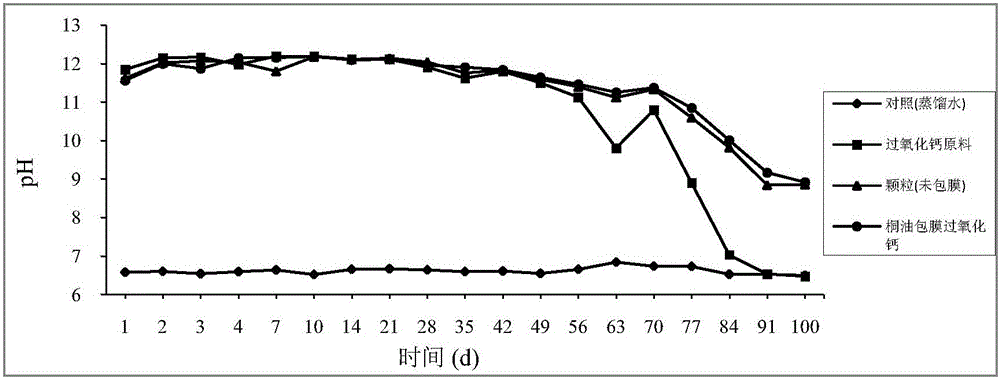

Controlled-release oxidizing agent with calcium peroxide as matrix and tung oil as coating and preparation method

A calcium peroxide and oxidant technology, applied in chemical instruments and methods, other chemical processes, organic fertilizers, etc., can solve the problems of short oxygen release time, unable to meet the demand for oxygen, etc. Oxygen time problem and the effect of improving rice growth environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

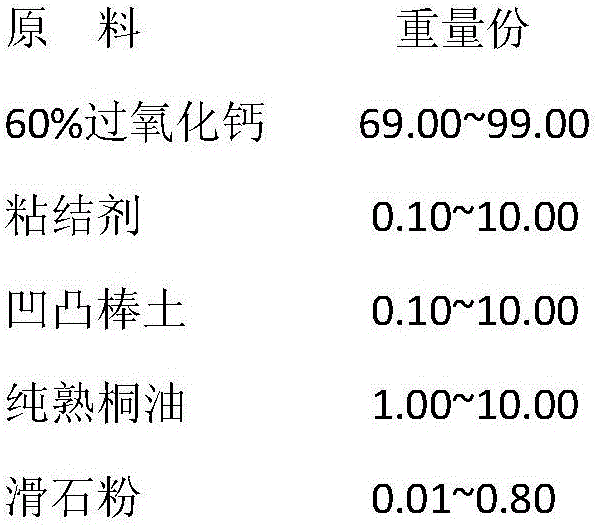

[0045] A kind of slow-release oxidant that takes calcium peroxide as matrix tung oil as coating, and it is made of the raw material of following weight part:

[0046]

[0047] A kind of preparation method that takes calcium peroxide as matrix tung oil as the sustained-release oxidant of coating, its steps are:

[0048] A.60% calcium peroxide raw powder granulation:

[0049] ①Pelleting: Adjust the inclination angle of the disk granulator to 60°, the speed to 30r / min, and the heating device to 40 or 44 or 46 or 48 or 50°C; take 1kg of calcium peroxide raw powder , divided into 10 equal parts, take one part into the disc, quickly use water mist to moisten it and granulate it, the particle size of the small particle is about 0.5mm, take it out for use, repeat the above steps until all 10 parts of powder are granulated .

[0050] ②Granulation: adjust the inclination angle of the disc granulator to 60°, adjust the speed to 30r / min, adjust the heating device to 40 or 44 or 46 or...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com