High-glossiness low-odor high-low-temperature-toughness flame-retardant PC/ABS (polycarbonate/acrylonitrile-butadiene-styrene) composition

A low-odor, high-low temperature technology, applied in high-low temperature tough flame-retardant PC/ABS composition, high gloss, low-odor field, can solve problems such as unfriendly smell, unfavorable material performance, etc., to avoid the precipitation of small molecular substances, cost The effect of low cost and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

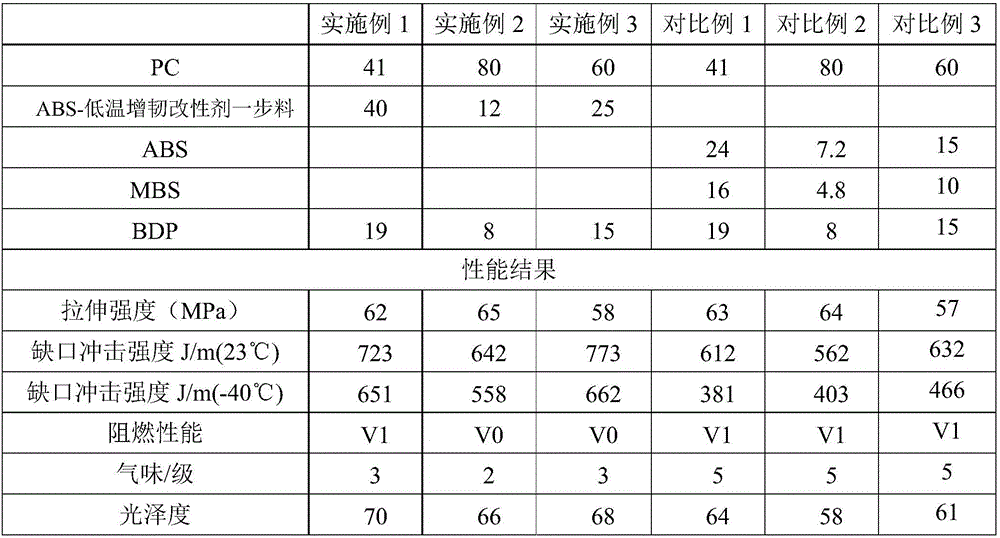

Embodiment 1

[0047] A high-gloss, low-odor, high-low temperature toughness flame-retardant PC / ABS composition is made of the following raw materials in mass percentage: polycarbonate 41%, BDP 19%, ABS-low temperature toughening modifier one-step material 40 %; wherein, the ABS-low temperature toughening modifier one-step material is made of raw materials including the following mass percentages: ABS 60%, MBS 40%; the molecular weight of the polycarbonate is 25000-37000; the The particle size of ABS is 0.1um-0.4um.

[0048] This ABS-low temperature toughening modifier one-step material is prepared by the method comprising the following steps:

[0049] (1) Put the ABS and the low-temperature toughening modifier into a high-mixer for mixing to obtain a premix;

[0050] (2) Put the premix into the main feeding port of the twin-screw extruder and extrude. The screw length-to-diameter ratio of the twin-screw extruder is 48:1, and the twin-screw extruder The melt extrusion conditions are: the tem...

Embodiment 2

[0053] A high-gloss, low-odor, high-low temperature toughness flame-retardant PC / ABS composition is made of the following raw materials in mass percentage: polycarbonate 80%, BDP 8%, ABS-low temperature toughening modifier one-step material 12 %; wherein, the ABS-low temperature toughening modifier one-step material is made of raw materials comprising the following mass percentages: ABS 60%, MBS 40%; the molecular weight of the polycarbonate is 25000-37000; The particle size of ABS is 0.1um-0.4um.

[0054] This ABS-low temperature toughening modifier one-step material is prepared by the method comprising the following steps:

[0055] (1) Put the ABS and the low-temperature toughening modifier into a high-mixer for mixing to obtain a premix;

[0056] (2) Put the premix into the main feeding port of the twin-screw extruder and extrude. The screw length-to-diameter ratio of the twin-screw extruder is 48:1, and the twin-screw extruder The melt extrusion conditions are: the tempe...

Embodiment 3

[0059] A high-gloss, low-odor, high-low temperature toughness flame-retardant PC / ABS composition is made of the following raw materials in mass percentage: polycarbonate 60%, BDP 15%, ABS-low temperature toughening modifier one-step material 25 %; wherein, the ABS-low temperature toughening modifier one-step material is made of raw materials comprising the following mass percentages: ABS 60%, MBS 40%; the molecular weight of the polycarbonate is 25000-37000; The particle size of ABS is 0.1um-0.4um.

[0060] This ABS-low temperature toughening modifier one-step material is prepared by the method comprising the following steps:

[0061] (1) Put the ABS and the low-temperature toughening modifier into a high-mixer for mixing to obtain a premix;

[0062] (2) Put the premix into the main feeding port of the twin-screw extruder and extrude. The screw length-to-diameter ratio of the twin-screw extruder is 48:1, and the twin-screw extruder The melt extrusion conditions are: the temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com