A kind of bisphenol Z-bisphenol AF copolycarbonate binding resin and its preparation method and application

A polycarbonate and bonding resin technology, used in adhesives, instruments, optics, etc., can solve problems such as operator safety and environmental hazards, and achieve the effects of simple and convenient post-processing methods, good film-forming properties, and suitable molecular weight distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

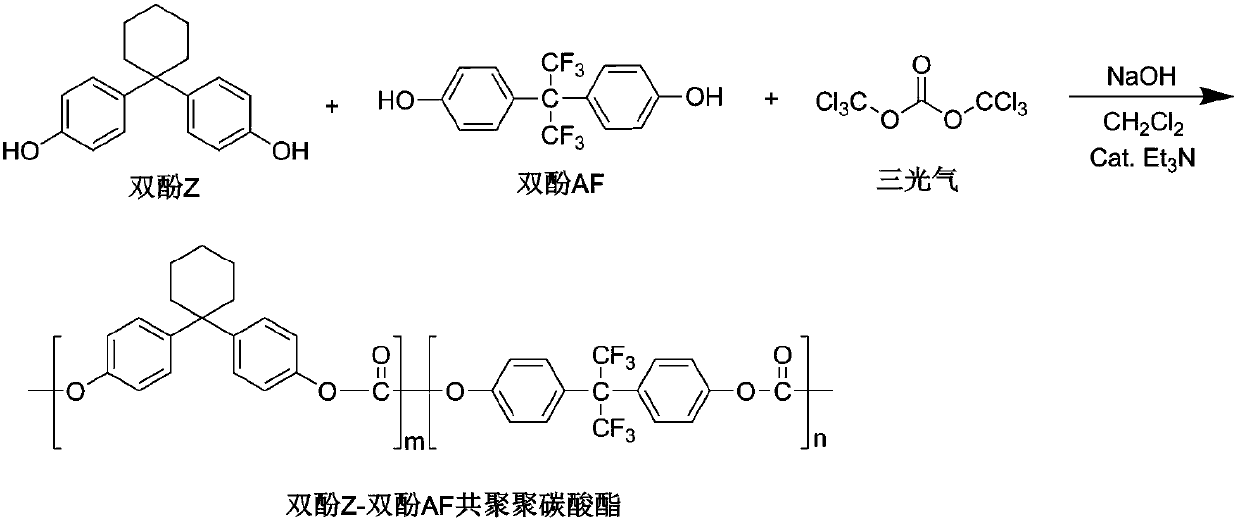

[0029] 2.68g (10mmol) bisphenol Z (1,1'-bis(4-hydroxyphenyl) cyclohexane), 3.36g (10mmol) bisphenol AF (2,2'-bis(4-hydroxyphenyl) Hexafluoropropane) was dissolved in 100 mL of 5% sodium hydroxide aqueous solution with stirring. After adding 0.23g (1mmol) benzyltriethylammonium chloride and 0.03mL (0.2mmol) triethylamine at 25°C, a dichloromethane solution of triphosgene [5.96g (20.1mmol) triphosgene dissolved in In 150mL of dichloromethane], after fully stirring for half an hour, the temperature was raised to 35°C for polycondensation reaction for 3 hours. After the reaction, the water phase was separated with a separatory funnel to obtain a dichloromethane solution containing bisphenol Z-bisphenol AF copolycarbonate. Synthetic route such as figure 1 shown.

[0030] The dichloromethane solution of bisphenol Z-bisphenol A copolycarbonate obtained in the previous step was washed with 0.1M NaOH solution, and then repeatedly washed with deionized water until the aqueous phase w...

Embodiment 2

[0032] 4.83g (18mmol) bisphenol Z (1,1'-bis(4-hydroxyphenyl) cyclohexane), 0.67g (2mmol) bisphenol AF (2,2'-bis(4-hydroxyphenyl) Hexafluoropropane) was dissolved in 100 mL of 5% sodium hydroxide aqueous solution with stirring. After adding 0.23g (1mmol) benzyltriethylammonium chloride and 0.03mL (0.2mmol) triethylamine at 25°C, a dichloromethane solution of triphosgene was added dropwise [6.53g (22mmol) triphosgene was dissolved in 150mL dichloromethane], after fully stirring for half an hour, the temperature was raised to 35°C for polycondensation reaction for 4 hours. After the reaction, the water phase was separated with a separatory funnel to obtain a dichloromethane solution containing bisphenol Z-bisphenol AF copolycarbonate. Synthetic route such as figure 1 shown.

[0033] The dichloromethane solution of bisphenol Z-bisphenol A copolycarbonate obtained in the previous step was washed with 0.1M NaOH solution, and then repeatedly washed with deionized water until the a...

Embodiment 3

[0035] 3.75g (14mmol) bisphenol Z (1,1'-bis(4-hydroxyphenyl) cyclohexane), 2.01g (6mmol) bisphenol AF (2,2'-bis(4-hydroxyphenyl) Hexafluoropropane) was dissolved in 200 mL of 2% sodium hydroxide aqueous solution under stirring. After adding 0.46g (2mmol) benzyltriethylammonium chloride and 0.06mL (0.4mmol) triethylamine at 25°C, a dichloromethane solution of triphosgene was added dropwise [3.56g (12mmol) triphosgene was dissolved in 120mL of dichloromethane], after fully stirring for half an hour, the temperature was raised to 35°C for 2 hours of polycondensation reaction. After the reaction, the water phase was separated with a separatory funnel to obtain a dichloromethane solution containing bisphenol Z-bisphenol AF copolycarbonate. Synthetic route such as figure 1 shown.

[0036]The dichloromethane solution of bisphenol Z-bisphenol A copolycarbonate obtained in the previous step was washed with 0.1M NaOH solution, and then repeatedly washed with deionized water until the...

PUM

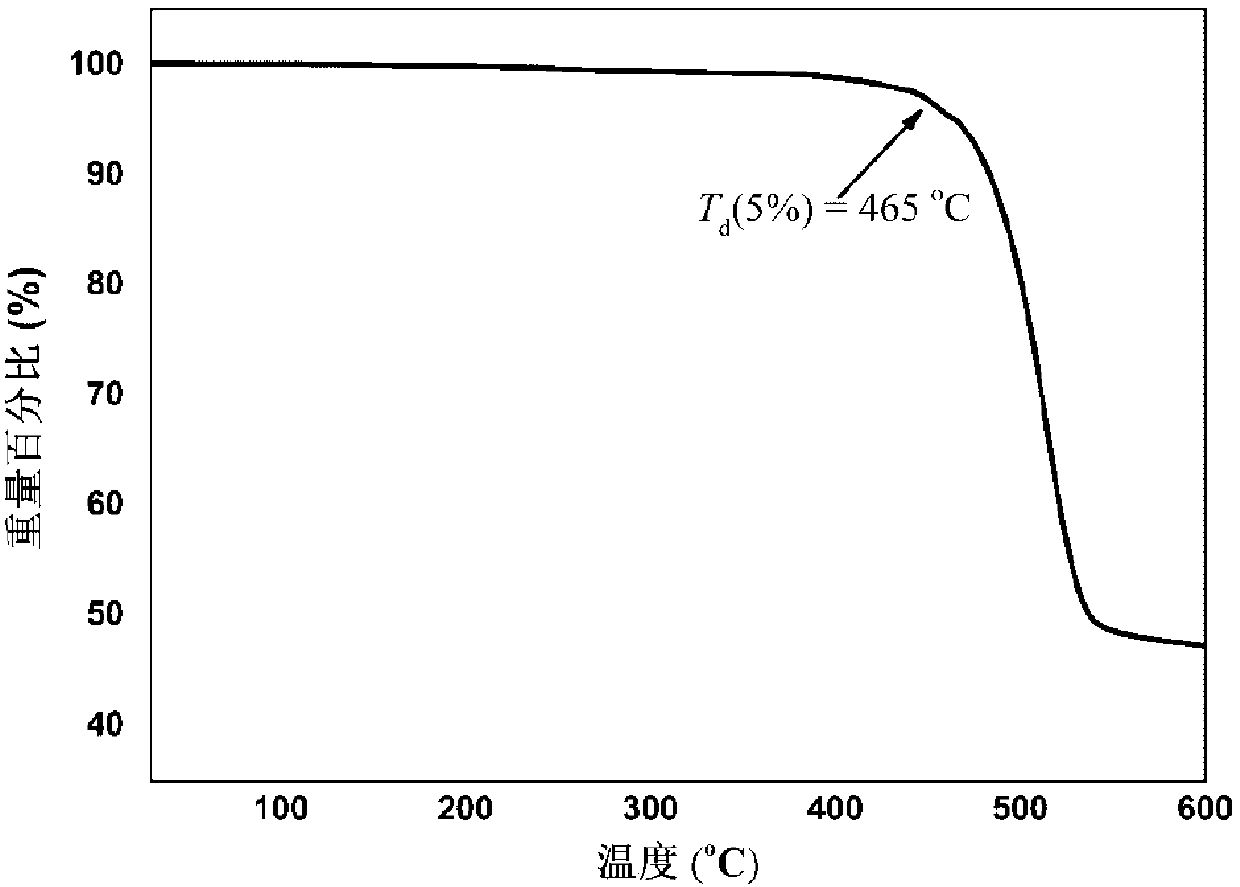

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| polydispersity index | aaaaa | aaaaa |

| polydispersity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com