A method for recovering and utilizing by-product hydrochloric acid in the process of preparing ADC blowing agent

A technology of ADC foaming agent and by-product hydrochloric acid, which is applied in the field of recycling by-product hydrochloric acid, can solve problems such as difficult removal of impurities, and achieve the effects of low application cost, simple and efficient treatment process, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

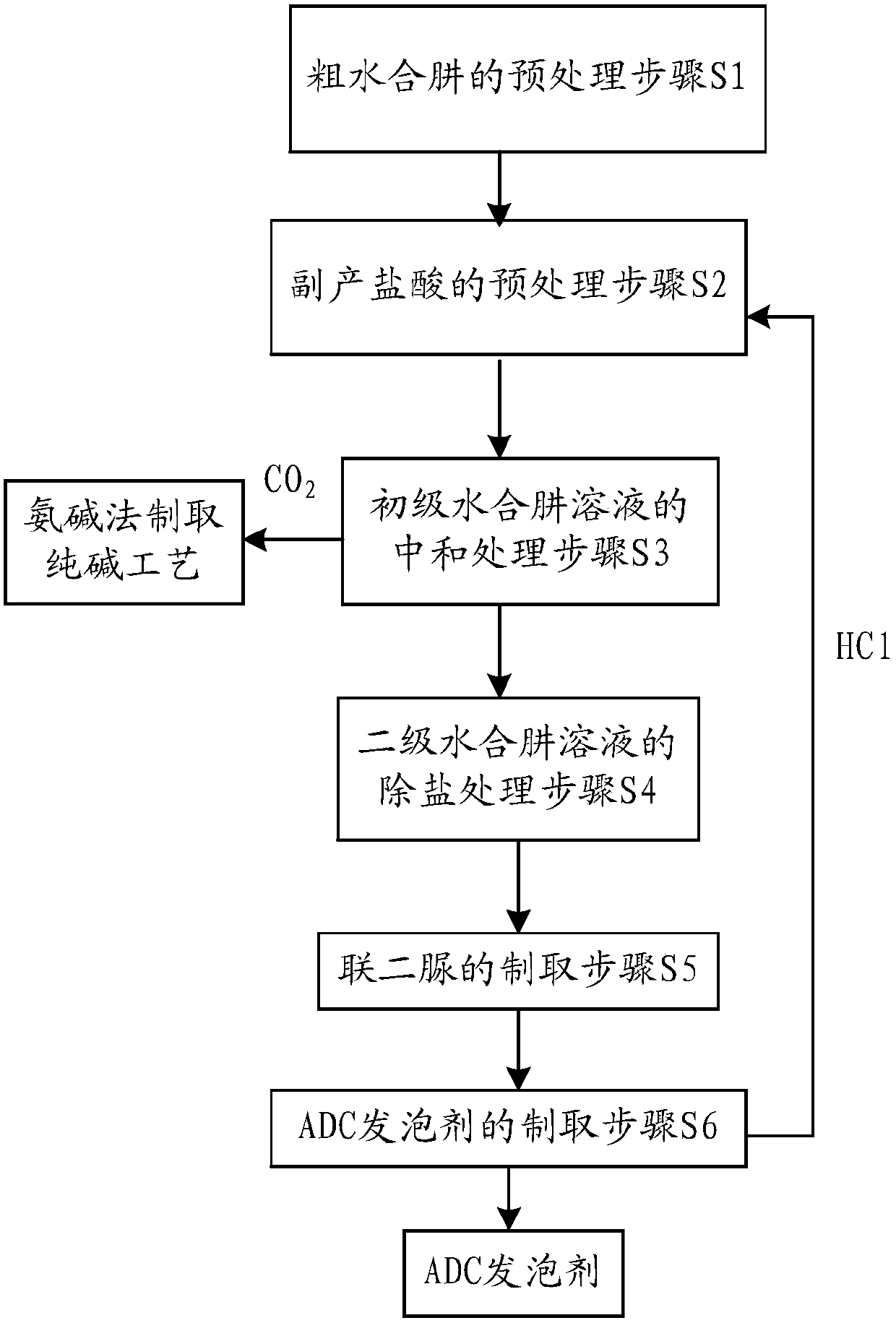

[0029] see figure 1 , this embodiment provides a method for recycling hydrochloric acid by-product during the preparation of ADC foaming agent, including:

[0030] Pretreatment step S1 of crude hydrazine hydrate: in this embodiment, the content of sodium carbonate in the crude hydrazine hydrate solution formed by the urea method is 142g / L, and the crude hydrazine hydrate is pretreated to make the crude hydrazine hydrate The sodium carbonate content is reduced to 80-90g / L, and the liquid phase obtained after separation of the crude hydrazine hydrate is the primary hydrazine hydrate solution. The above-mentioned pretreatment operation can be a freezing method or a reaction method. The specific operation process of the freezing method is to use a cold source to lower the temperature of the crude hydrazine hydrate solution, so that it is cooled to between -2 and 0°C, so that the crude hydrazine hydrate solution part of the sodium carbonate to form sodium carbonate decahydrate cry...

Embodiment 2

[0045] see figure 1 , this embodiment provides a method for recycling hydrochloric acid by-product during the preparation of ADC foaming agent, including:

[0046] Pretreatment step S1 of crude hydrazine hydrate: In this example, the content of sodium carbonate in the crude hydrazine hydrate solution formed by the urea method is 142 g / L, and the crude hydrazine hydrate solution uses normal temperature circulating water and ethylene glycol at -15°C The aqueous solution cools it step by step, so that the crude hydrazine hydrate itself cools down to -1°C. During the cooling process of the crude hydrazine hydrate, part of the sodium carbonate forms sodium carbonate decahydrate crystals, and the crude hydrazine hydrate after freezing treatment is processed by centrifugation. Process, to separate the sodium carbonate decahydrate crystal, obtain the primary hydrazine hydrate solution that sodium carbonate content is 90g / L;

[0047] Pretreatment step S2 of by-product hydrochloric aci...

Embodiment 3

[0057] see figure 1 , this embodiment provides a method for recycling hydrochloric acid by-product during the preparation of ADC foaming agent, including:

[0058] Pretreatment step S1 of crude hydrazine hydrate: In this example, the content of sodium carbonate in the crude hydrazine hydrate solution formed by the urea method is 142 g / L, and the crude hydrazine hydrate solution uses normal temperature circulating water and ethylene glycol at -15°C The aqueous solution cools it step by step, so that the crude hydrazine hydrate itself cools down to -2°C. During the cooling process of the crude hydrazine hydrate, part of the sodium carbonate forms sodium carbonate decahydrate crystals, and the crude hydrazine hydrate after freezing treatment is subjected to centrifugal operation. Process, to separate the sodium carbonate decahydrate crystal, obtain the primary hydrazine hydrate solution that sodium carbonate content is 80g / L;

[0059] Pretreatment step S2 of by-product hydrochlo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com