Large slope lifting device for strip mine dump truck

A technology of dump trucks and large gradients is applied in the mining of open pit mines, lifting equipment in mines, elevators, etc. It can solve the problems of air pollution in mines, increase transportation costs, and low lifting capacity, and shorten transportation distance. time, reducing the amount of infrastructure excavation, and reducing the effect of exhaust pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

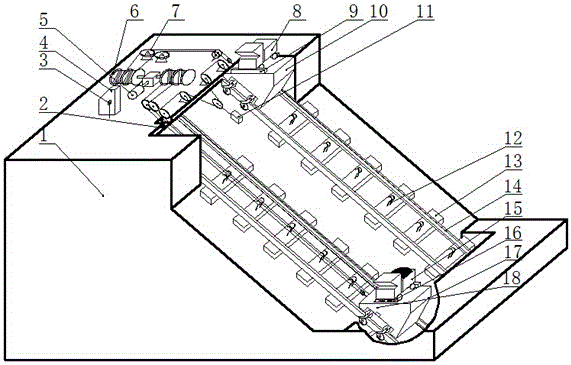

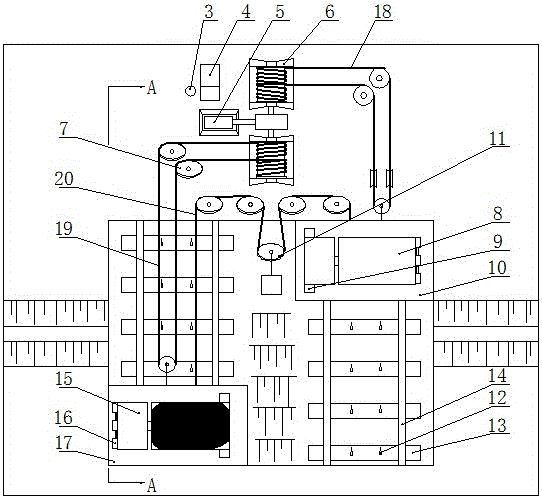

[0028] The present invention will be further described below in conjunction with accompanying drawing.

[0029] like figure 1 and figure 2As shown, a large-slope hoisting device for an open-pit mine dump truck includes a power hoisting device, a guiding device, a limit positioning device, a monitoring control device and a safety protection device; the power hoisting device includes a motor 5, a winding hoist 6, Wheeled trolley, the output shaft of the motor 5 is connected to the winding hoist 6; the guiding device includes rail pulley 45, channel steel track 14 and steel wire rope 19; the limit positioning device includes a fixed block arranged on the wheeled trolley 9. Rolling hydraulic block 16 and docking platform; the monitoring control device includes display controller 4, depth indicator 3, displacement sensor 18, hydraulic station 28, upstroke switch 2, downstroke switch 22, depth indicator 3, displacement Sensor 18, hydraulic station 28, upstroke switch 2, and downs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com