High-rise outer wall cleaning and spray-painting all-in-one machine

An exterior wall cleaning and all-in-one machine technology, which is applied in the field of inkjet printing all-in-one machine, high-rise exterior wall cleaning, can solve the problems of no printing, single machine cleaning, single spraying, etc., to achieve convenient loading and unloading, vivid colors, cost and time saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

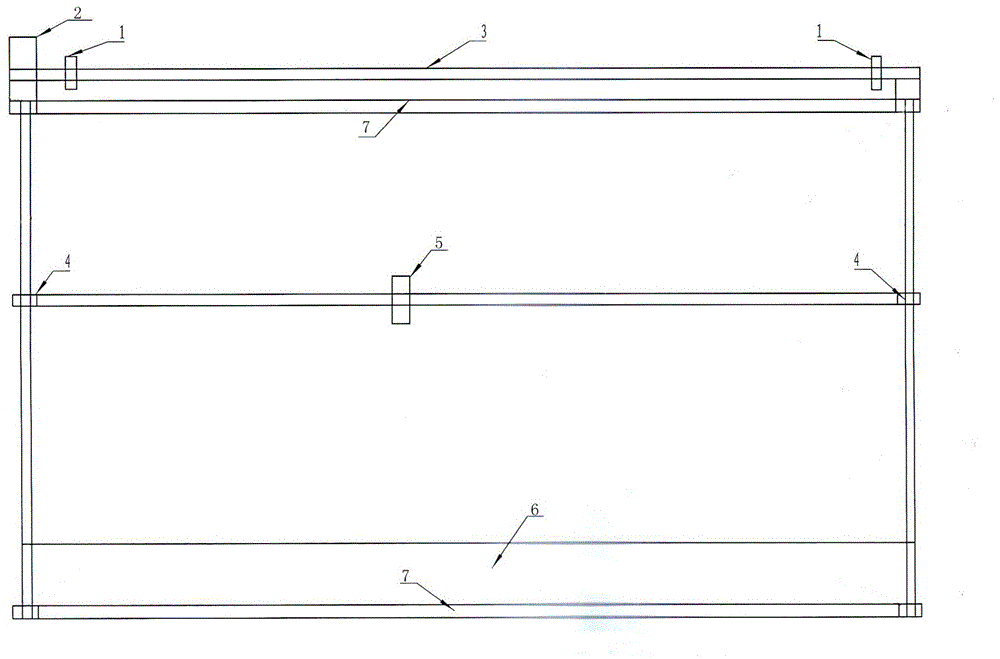

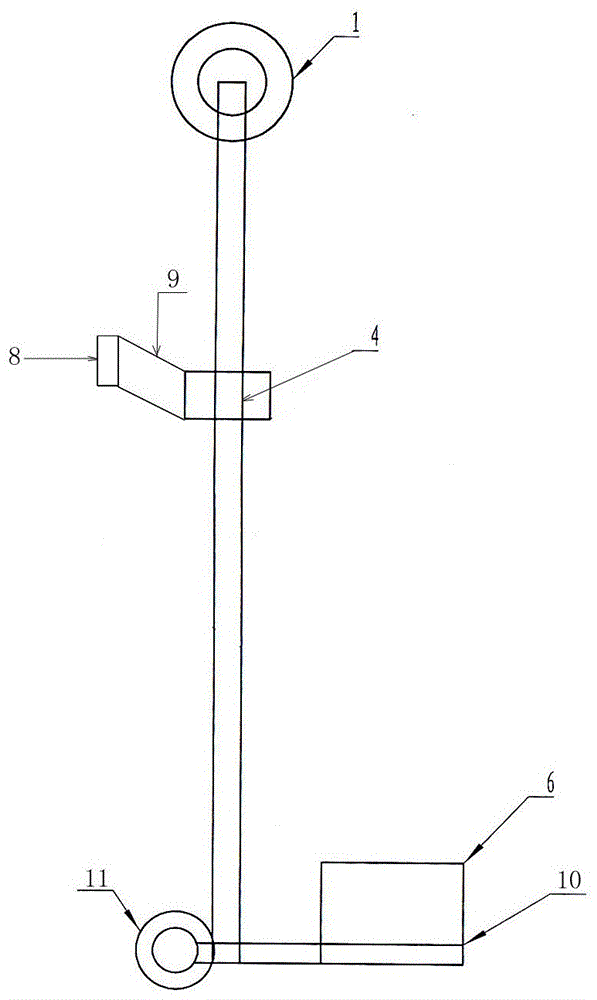

[0032] like figure 1 and figure 2 As shown, the high-rise exterior wall cleaning and inkjet integrated machine includes an up and down moving part 4, a horizontal moving part 5, a control part, a connecting steel frame 7 and a lifting part of the whole machine, and the connecting steel frame 7 is connected to both ends of the up and down moving part 4, The up and down moving part 4 is connected with the horizontal moving part 5, and the horizontal moving part 5 is provided with a mechanical arm 9, and the nozzle 8 is installed on the mechanical arm 9, and the sensor device is installed at the front end of the mechanical arm 9 to control the nozzle 8, and the control part is arranged in the up and down moving part 4 In the chassis 6 at the bottom, a supporting steel frame 10 is provided at the bottom of the chassis 6. The control part is used to control the coordination of various parts. The top of the up and down moving part 4 is provided with a lifting part of the whole mach...

Embodiment 2

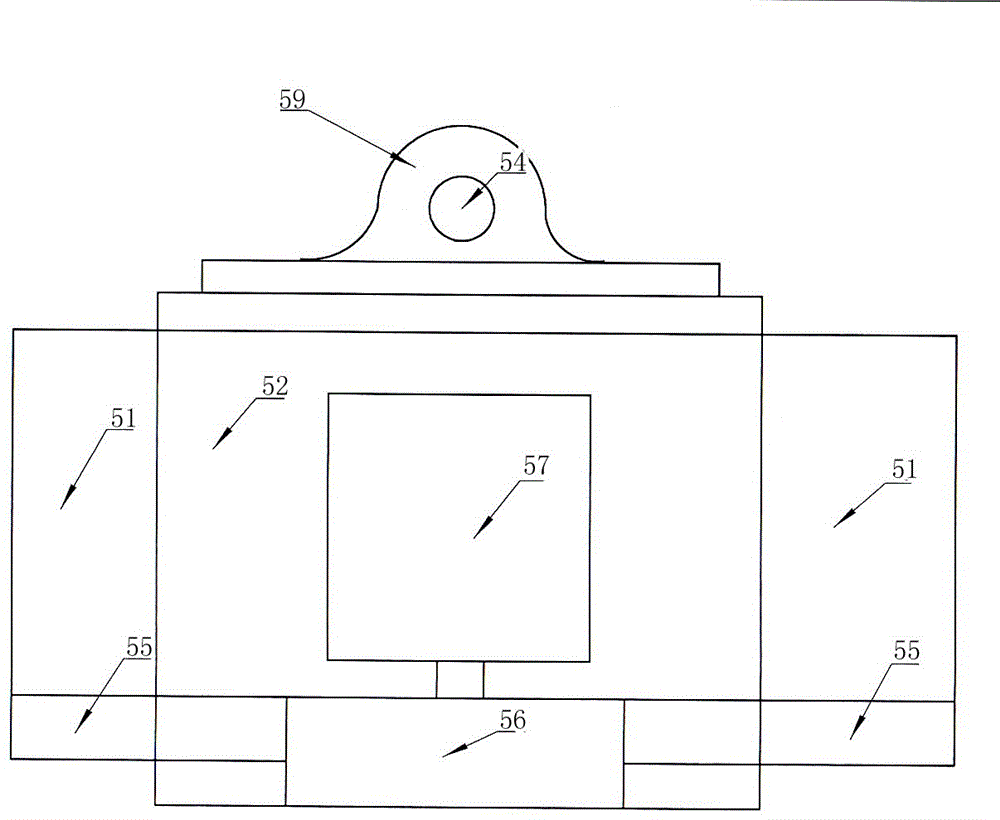

[0043] The all-in-one machine for cleaning and printing of high-rise exterior walls includes an up and down moving part, a horizontal moving part, a control part and a lifting part of the whole machine. The up and down moving part is connected with the horizontal moving part. , the front end of the mechanical arm is equipped with an induction device to control the cleaning head. The control part is set in the chassis at the bottom of the up and down moving part. The control part is used to control the coordination of various parts. It is used to control the overall up and down movement of the machine.

[0044] Among them, there is a cleaning brush at the rotatable part of the cleaning head, and the inner side is a cleaning wipe composed of cotton threads. When working, an appropriate amount of cleaning agent is sprayed to ensure the cleanliness of the cleaning surface. The sprayed cleaning agent is mainly used to scrub the wall. And glass curtain wall, there is a nozzle in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com