Edge embosser equipment used for processing thin paper scrolls

An embossing machine and edge technology, which is applied in the field of edge embossing machine equipment for processing thin paper rolls, can solve problems such as texture disturbance, influence on equipment promotion, influence on paper, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

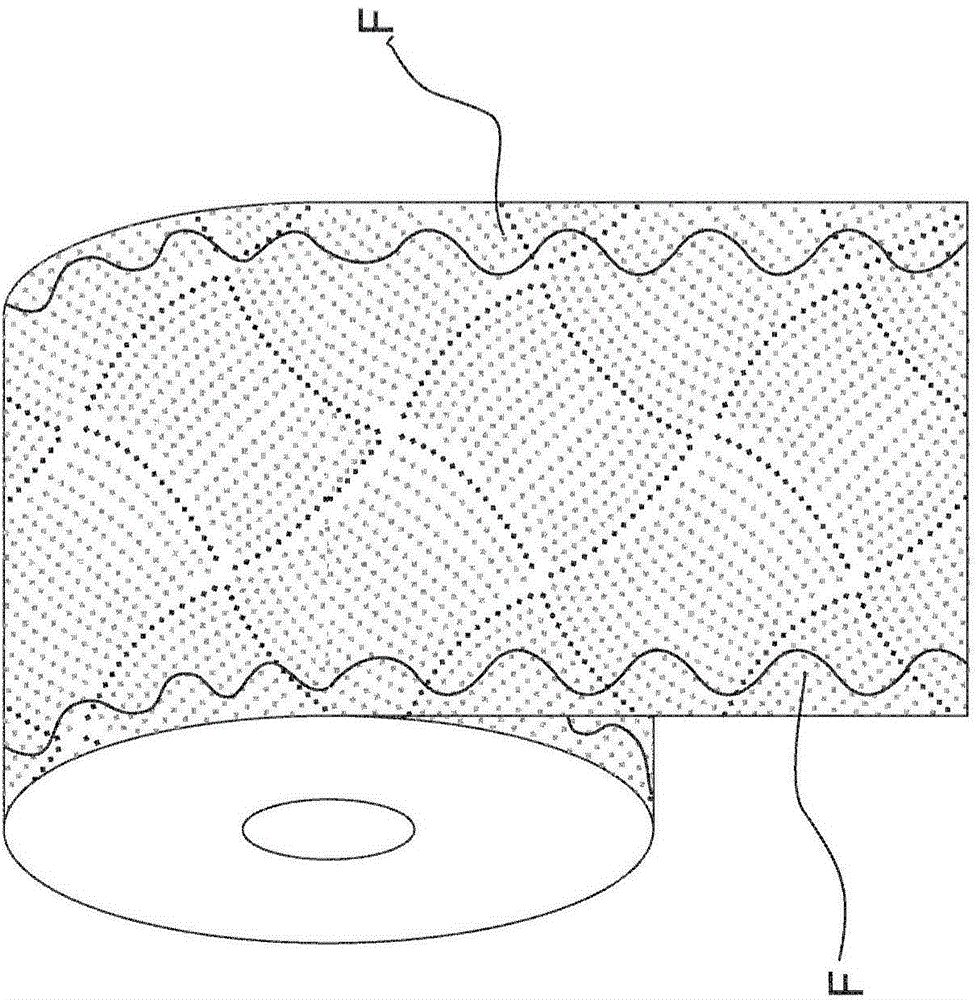

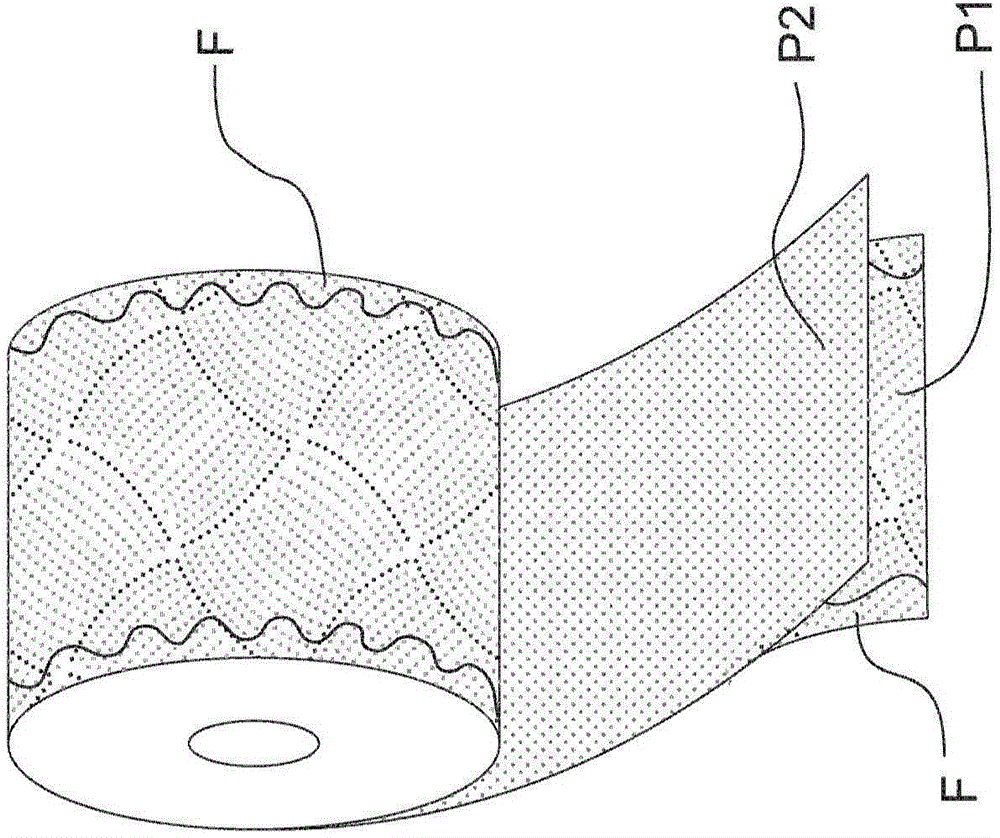

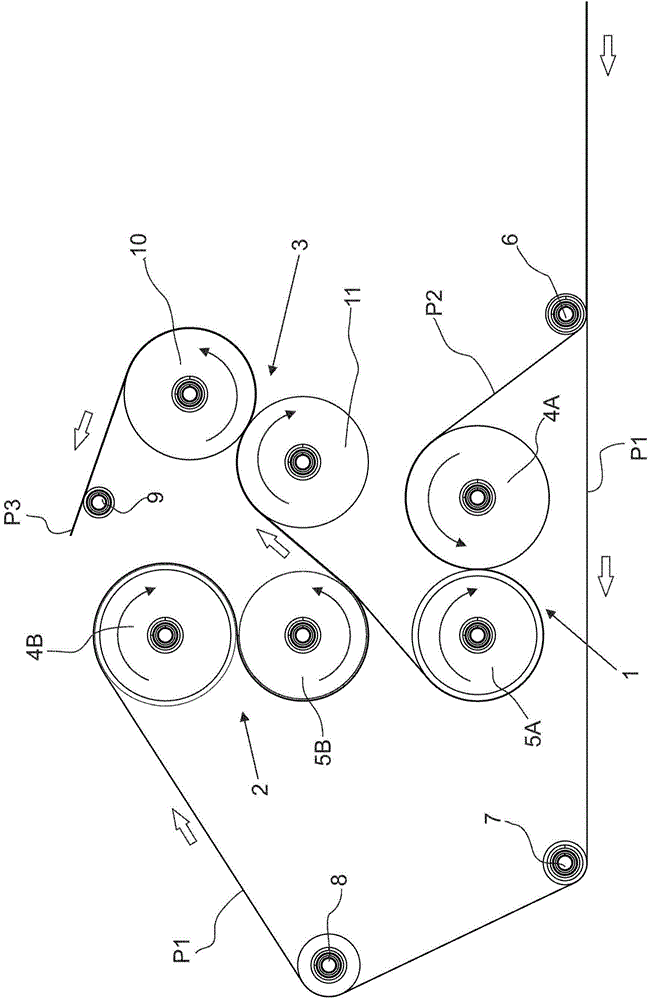

[0029] According to these diagrams and their details, especially Figure 3-8 , in a preferred embodiment, the embossing machine equipment for paper processing includes three processing stations, two processing stations (1) and (2) for engraving, one processing station (3) for connecting, and three Between the two processing stations there is a continuous belt of plain paper, where (P1) is the lower or inner belt and (P2) is the upper or outer belt, so that in the two first stations (1) and (2) the Any pattern is embossed on the inner and outer strips, which are then joined at their edges by a station (3) forming a continuous strip (P3) of finished paper.

[0030] Each engraving station (1) and (2) comprises a pair of rollers, one roller is made of rubber (4A-4B), and the other roller is made of engraved steel (5A-5B), and the latter is made by passing through each Corresponding continuous inner and outer belts (P1 or P2) of paper are drawn between the rollers and guided by ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com