Brake disc machining knife and machining method thereof

A technology for processing cutting tools and brake discs, which is applied in the direction of manufacturing tools, metal processing equipment, and cutting tools for lathes, etc. It can solve the problems that the processing accuracy cannot be guaranteed, and achieves avoiding unstable vibration, high-precision positioning, and ensuring connection strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

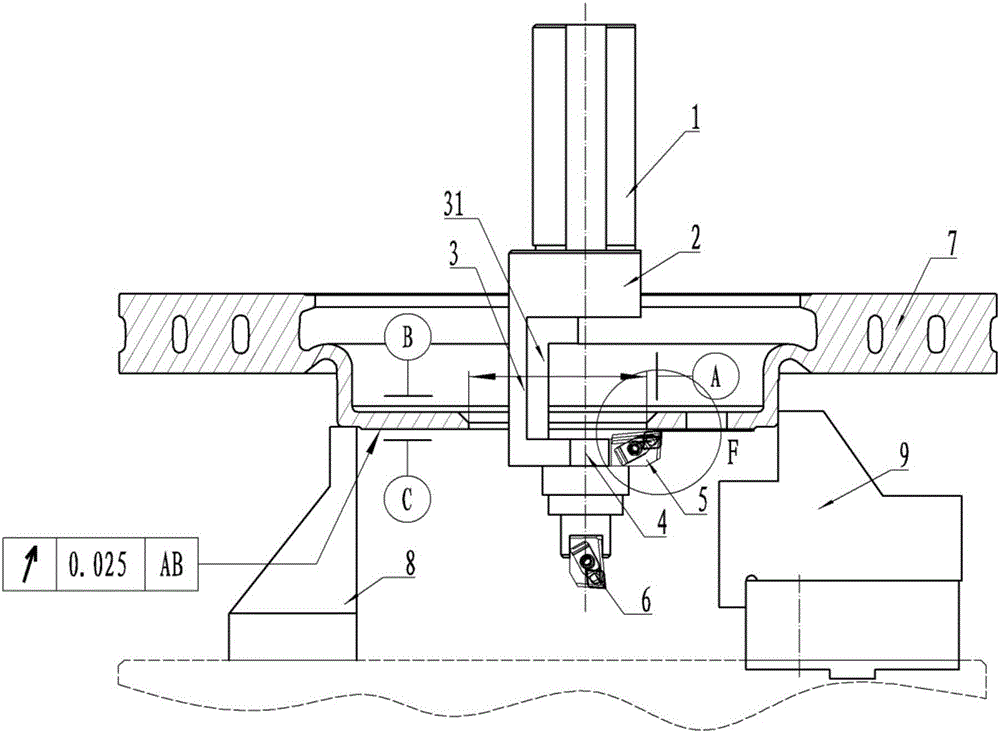

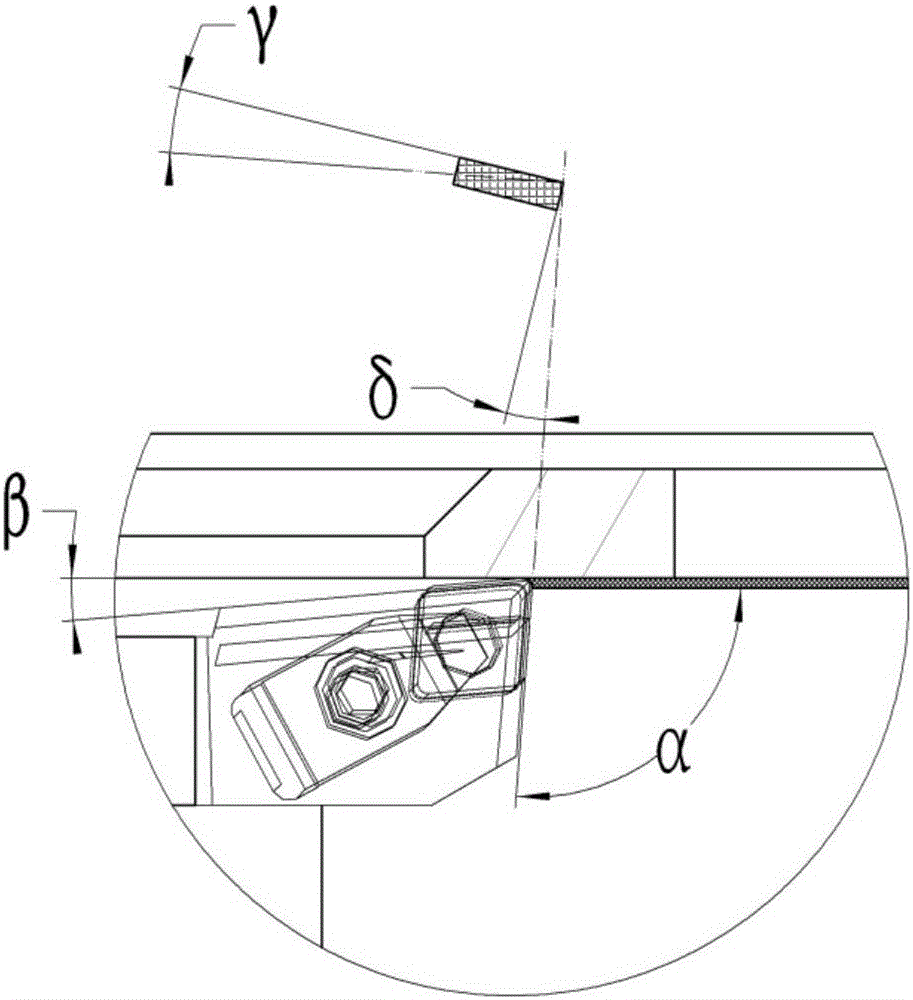

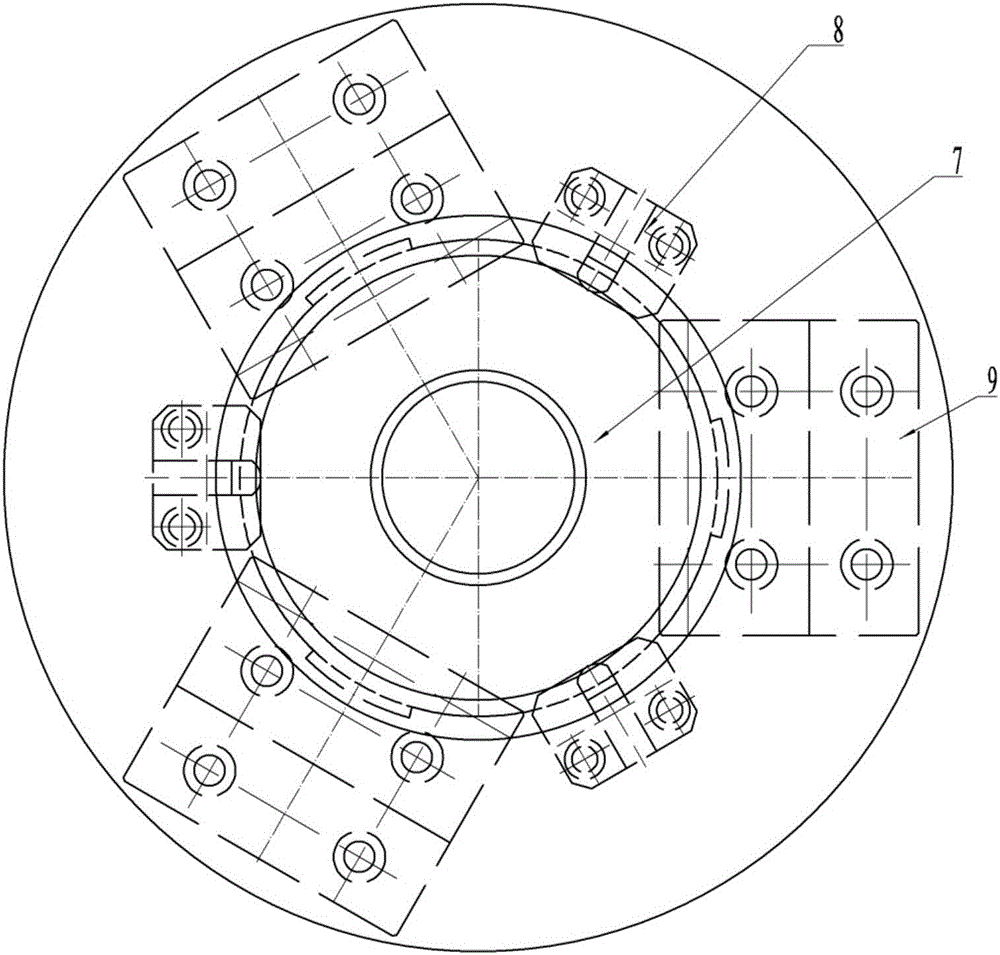

[0046] A brake disc processing tool, such as Figure 1 to Figure 13 As shown, the brake disc 7 is a disc-shaped part with a boss, and the center of the brake disc 7 is provided with a central hole. One side protruding from the boss is a convex surface, which is the wheel mounting surface C, and the other side is a concave surface, which is the hub mounting surface B. , the axis of the center hole is the datum A. The brake disc 7 is positioned with the convex surface of the boss, three positioning blocks 8 are arranged below the convex surface, the positioning blocks 8 are against the pre-processed positioning edge at the edge of the convex surface, and three clamping claws 9 are arranged on the outer surface of the boss. In order to ensure the positioning accuracy, after the positioning surfaces of the three positioning blocks are processed, they are fina...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface smoothness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com