Preparation method of platinum tin silica catalyst for hydrogenation of acetic acid to produce ethanol

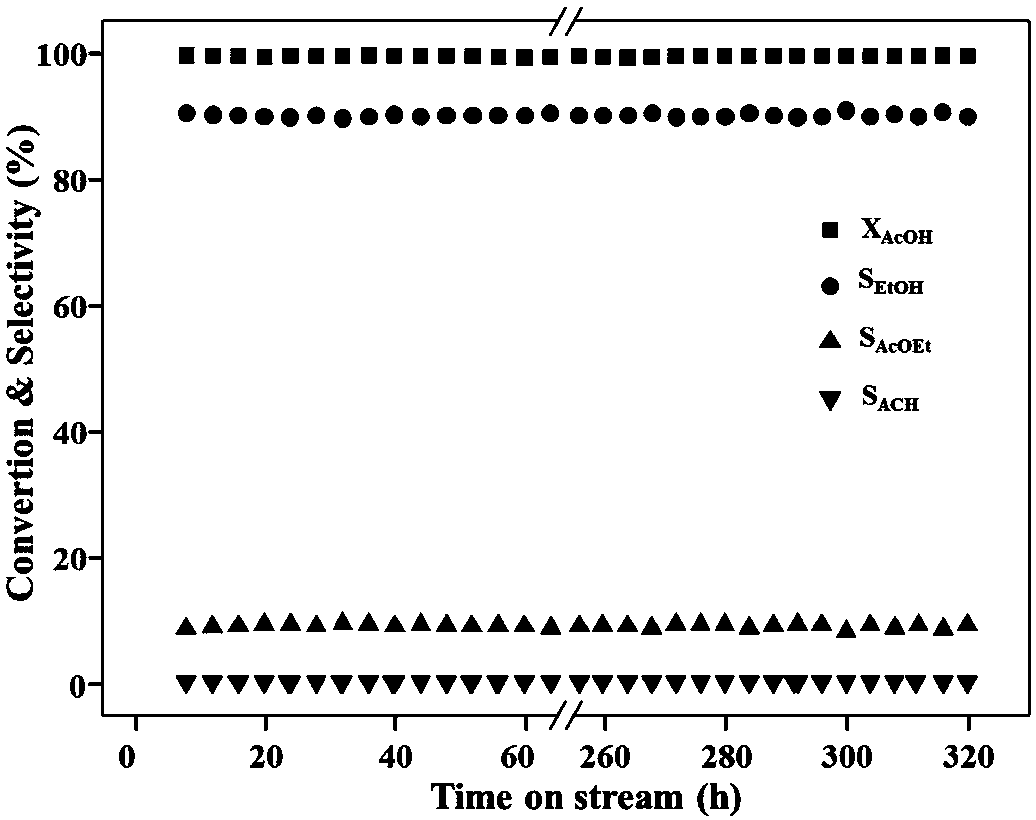

A technology of silica and catalyst, which is applied in the chemical industry, can solve the problems of acetic acid production enterprises such as sluggish profits, low dispersion of active components, and harsh reaction conditions, and solve the problems of overcapacity, high activity, selectivity, and stability of acetic acid Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

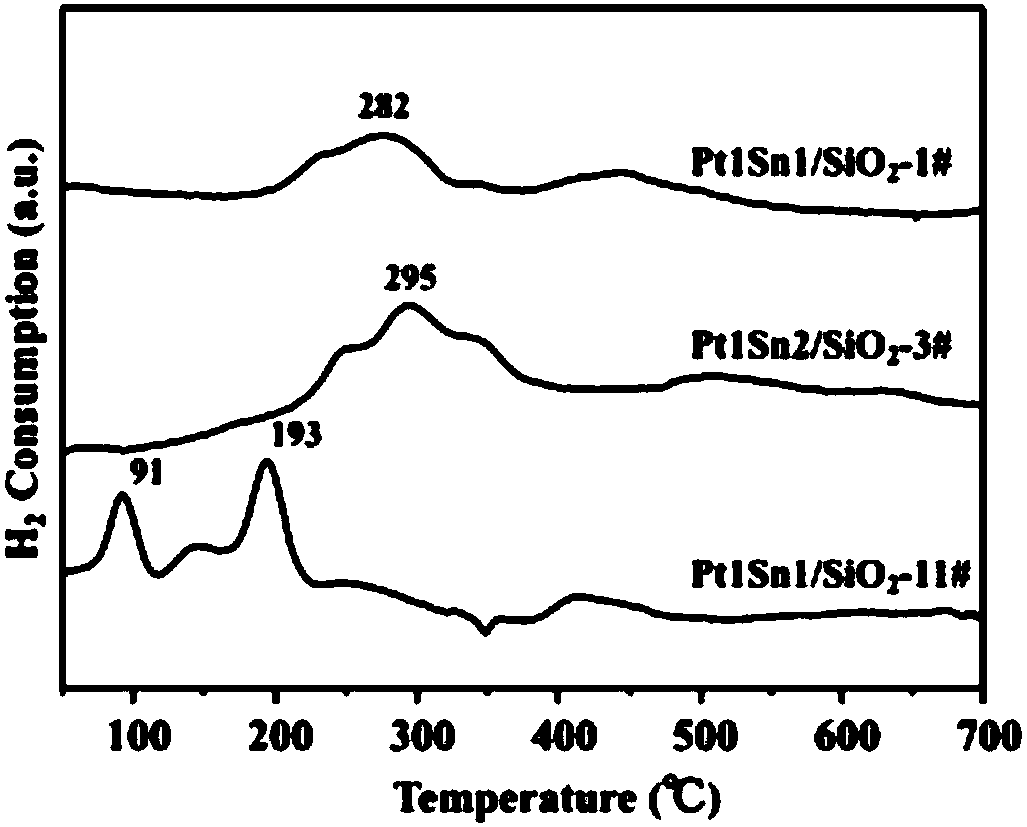

[0026] Example 1: Pt1Sn1 / SiO 2 -1# Catalyst

[0027] 0.393g SnCl 2 Dissolve in 50.2mL of absolute ethanol, add 70.766g of tetraethyl orthosilicate, add dropwise 50.1mL of deionized water while stirring, adjust the pH value of the sol to 3.0, wait for the dropwise addition of water to stand at room temperature until it becomes After gelling, it was aged at 70°C for 10 hours, washed to remove chloride ions, dried in an oven at 110°C for 8 hours, and then baked in a muffle furnace at 500°C for 5 hours to obtain SnO x / SiO 2 Composite carrier, the carrier is fully ground to obtain a powdery solid.

[0028] 4g SnO x / SiO 2 Add the composite carrier powder to the aqueous ammonia solution, add 4mL tetraammonium platinum chloride aqueous solution (0.01gPt / mL) under stirring, continue to stir for 10 hours, add ammonia water dropwise in time to keep the pH=11.0, then filter to wash away the chloride ions, Dry at 200°C for 5 hours. The catalyst powder was pressed into tablets, cru...

Embodiment 2

[0029] Example 2: Pt0.5Sn0.5 / SiO 2 -2# Catalyst

[0030] 0.212g SnCl 2 Dissolve in 30.8mL of absolute ethanol, add 70.766g of tetraethyl orthosilicate, add 30.2mL of deionized water dropwise while stirring, adjust the pH value of the sol to 4.2, wait until the water is added dropwise and let it stand at room temperature until it becomes After gelling, it is aged at 70°C for 10 hours, washed to remove chloride ions, dried in an oven at 95°C for 10 hours, and then baked in a muffle furnace at 600°C for 2 hours to obtain SnO x / SiO 2 Composite carrier, the carrier is fully ground to obtain a powdery solid.

[0031] 4g SnO x / SiO 2 Add the composite carrier powder into the ammonia solution, add 2mL tetraammonium platinum chloride aqueous solution (0.01gPt / mL) while stirring, continue to stir for 24 hours, add ammonia water dropwise in time to keep the pH = 9.0, then filter to wash away the chloride ions, 110 °C for 10 hours. The catalyst powder was pressed into tablets, cru...

Embodiment 3

[0032] Example 3: Pt2Sn1 / SiO 2 -3# Catalyst

[0033] 0.393g SnCl 2 Dissolve in 75.2mL of absolute ethanol, add 70.766g of tetraethyl orthosilicate, add 61.2mL of deionized water dropwise while stirring, adjust the pH value of the sol to 5.0, wait until the water is added dropwise and let it stand at room temperature until it becomes After gelling, it was aged in a water bath at 50°C for 48 hours, washed to remove chloride ions, dried in an oven at 120°C for 5 hours, and then baked in a muffle furnace at 400°C for 10 hours to obtain SnO x / SiO 2 Composite carrier, the carrier is fully ground to obtain a powdery solid.

[0034] 4g SnO x / SiO 2 Add the composite carrier powder into the ammonia solution, add 8mL tetraammonium chloride platinum chloride aqueous solution (0.01gPt / mL) under stirring, continue stirring for 6 hours, add ammonia water dropwise at the right time to keep the pH = 12.0, then filter to wash away the chloride ions, 60 °C for 48 hours. The catalyst pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com