Preparation method for titanium dioxide/graphene aerogel with high specific surface area

A graphene aerogel, high specific surface area technology, applied in chemical instruments and methods, chemical/physical processes, catalyst carriers, etc., can solve the problems of low photocatalytic efficiency and no visible light response, and achieve large specific surface area, electrical conductivity The effect of high rate and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

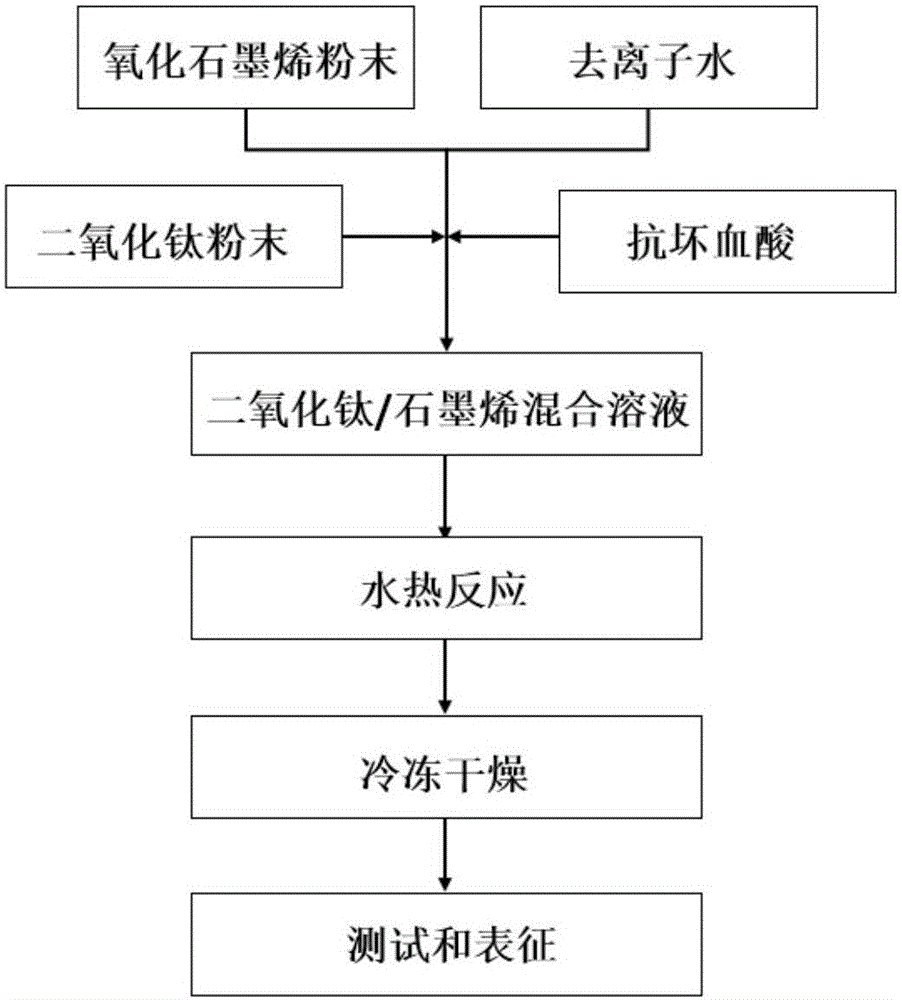

Method used

Image

Examples

Embodiment 1

[0034] Take 32mg of graphene oxide powder, add 16mL of deionized water, ultrasonically disperse for 2 hours, then mechanically stir until a well-dispersed and stable graphene oxide aqueous solution is formed; add 10.67mg of titanium dioxide powder to the prepared graphene oxide aqueous solution, Stir mechanically for 1 hour to form a well-dispersed titanium dioxide / graphene oxide mixed solution; add 50 mg of ascorbic acid to the above mixed solution, stir evenly, transfer to a hydrothermal reaction kettle, and react at a constant temperature of 90°C for 6 hours to prepare a three-dimensional titanium dioxide / graphene hydrogel; freeze-drying at -60~-50°C for 24 hours to obtain titanium dioxide / graphene airgel with high specific surface area.

Embodiment 2

[0036] Take 32 mg of graphene oxide powder, add 16 mL of deionized water, ultrasonically disperse for 2 hours, and then mechanically stir until a well-dispersed and stable graphene oxide aqueous solution is formed; add 32 mg of titanium dioxide powder to the prepared graphene oxide aqueous solution, and mechanically Stir for 1 hour to form a well-dispersed titanium dioxide / graphene oxide mixed solution; add 50 mg of ascorbic acid to the above mixed solution, stir evenly, transfer to a hydrothermal reaction kettle, and react at a constant temperature of 90°C for 6 hours to prepare a three-dimensional titanium dioxide / graphene oxide Graphene hydrogel; freeze-dry at -60~-50°C for 24 hours to obtain titanium dioxide / graphene airgel with high specific surface area.

Embodiment 3

[0038] Take 32 mg of graphene oxide powder, add 16 mL of deionized water, ultrasonically disperse for 2 hours, and stir mechanically until a well-dispersed and stable graphene oxide aqueous solution is formed; add 96 mg of titanium dioxide powder to the prepared graphene oxide aqueous solution, and mechanically Stir for 1 hour to form a well-dispersed titanium dioxide / graphene oxide mixed solution; add 50 mg of ascorbic acid to the above mixed solution, stir evenly, transfer to a hydrothermal reaction kettle, and react at a constant temperature of 90°C for 6 hours to prepare a three-dimensional titanium dioxide / graphene oxide Graphene hydrogel; freeze-dry at -60~-50°C for 24 hours to obtain titanium dioxide / graphene airgel with high specific surface area.

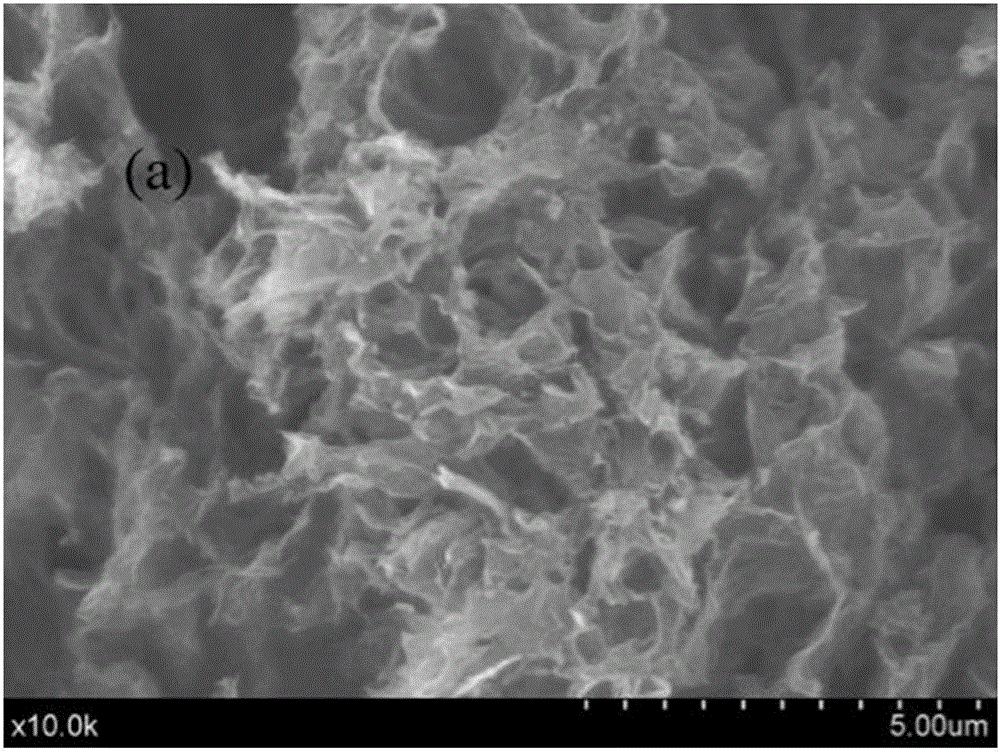

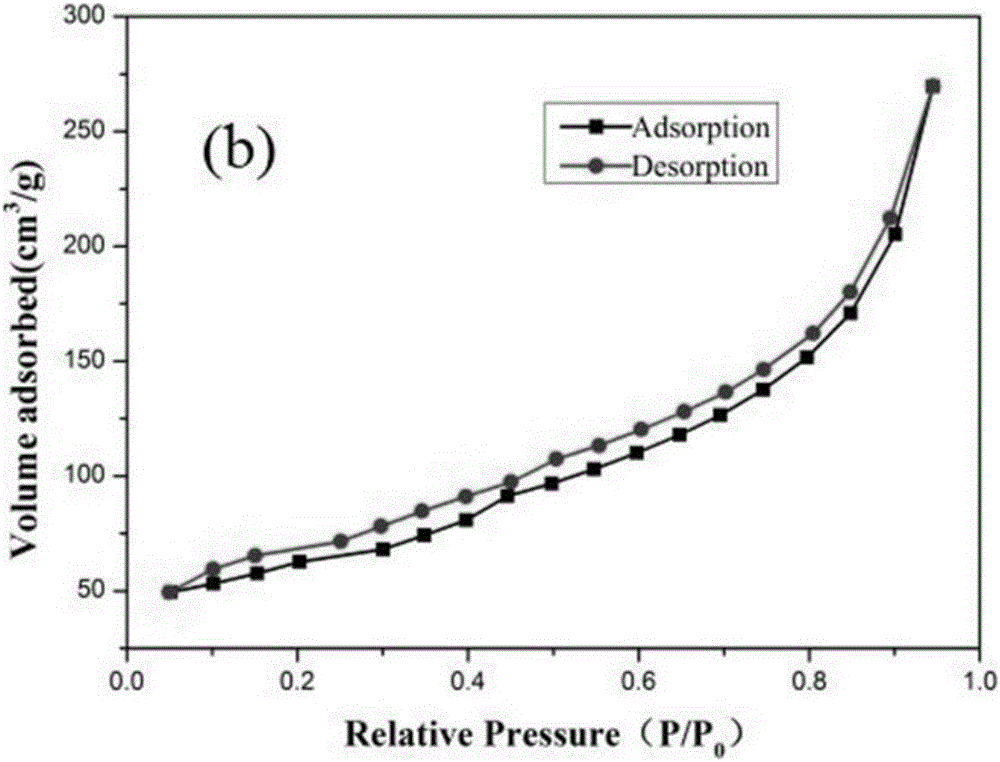

[0039] The titanium dioxide / graphene airgel obtained in the above examples has been observed by a scanning electron microscope (SEM), figure 2 , Figure 4 and Image 6 The SEM spectra of titanium dioxide / graphene aerogel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com