Combined device for washing tail gas and treating waste water of low-speed diesel engine of ship

A tail gas washing and wastewater treatment technology, which is applied in the direction of gaseous effluent wastewater treatment, gas treatment, water/sewage treatment, etc., can solve the problems of multiple reaction vessels, large energy consumption and high cost of oxidation devices, and achieve enhanced micro-mixing, installation Easy maintenance and small gas phase pressure drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

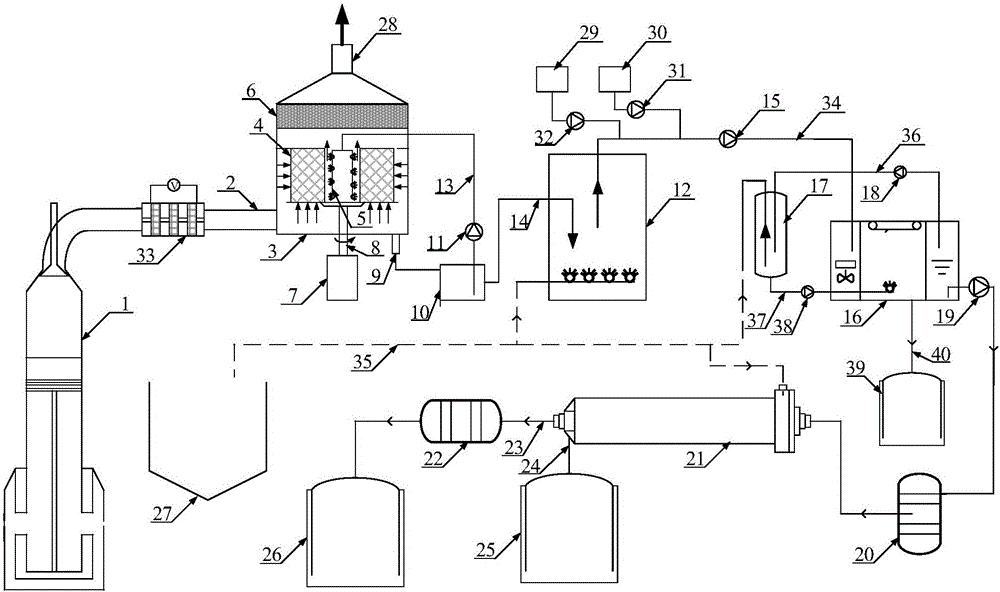

[0018] The present invention is described in more detail below in conjunction with accompanying drawing example:

[0019] combine figure 1 , The compound device for exhaust gas washing and wastewater treatment of marine low-speed diesel engines of the present invention mainly includes: a high-gravity exhaust gas washing system and a wastewater treatment system. The high-gravity tail gas scrubbing system mainly includes: high-gravity scrubber 3, catalytic oxidation reactor 33, circulation pump 11, buffer tank 10; wastewater treatment system includes: aeration tank 12, dissolved air tank 17, air flotation tank 16, activated carbon filter 20. Reverse osmosis membrane reactor 21, precision filter 22, concentrated brine storage tank 25, clean water storage tank 26; wherein the supergravity washing tower 3 includes: packing layer 4, demister 6, liquid distributor 5, motor 7 . The exhaust gas discharged from the engine 1 passes through the exhaust pipeline 2, and is connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com