A kind of anti-self-polymerizing rectification column tray

A rectification tower and self-polymerization technology, which is applied in the direction of distillation separation, chemical instruments and methods, separation methods, etc., can solve the problems of plate efficiency reduction, influence on product quality, and large gradient of material import and export, and achieve the elimination of flow dead angle, Overcoming the effect of large flow gradient and preventing self-aggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the drawings:

[0023] See figure 1 , figure 2 with image 3 .

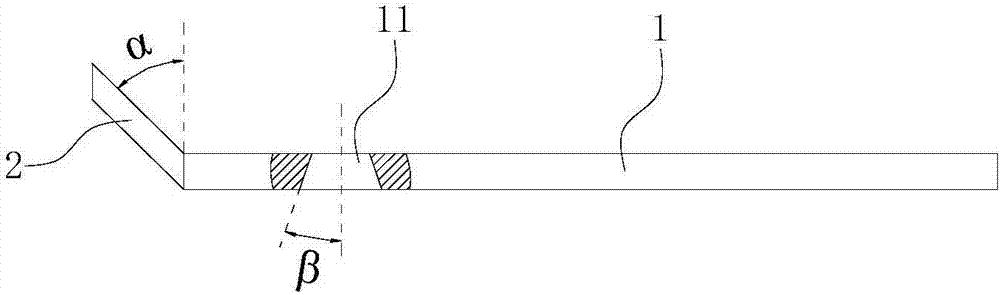

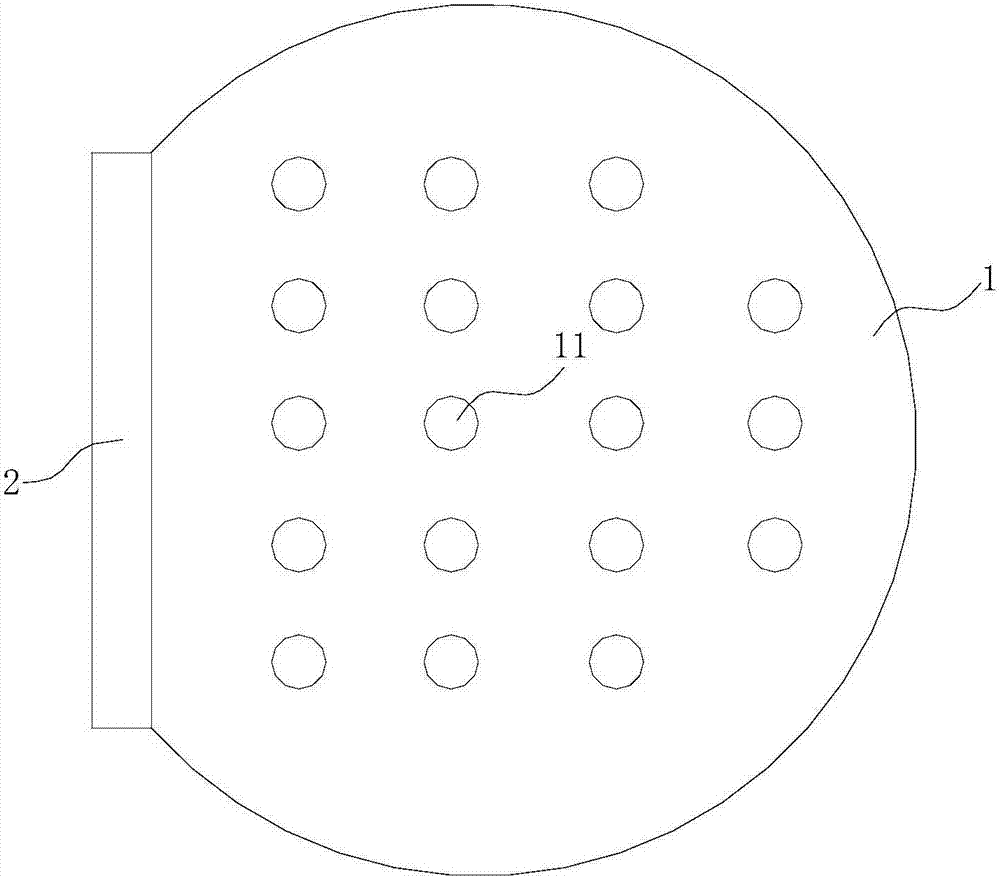

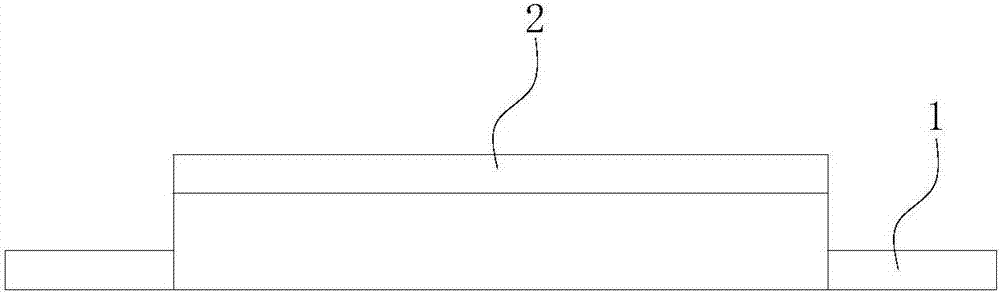

[0024] The present invention is an anti-self-aggregation rectification tower tray, comprising a plate body 1 on which an overflow weir 2 is arranged, and the overflow weir 2 is arranged obliquely along the flow direction of the material.

[0025] The inclination described here is relative to the existing vertical overflow weir. Generally, the inclination angle of the overflow weir 2 ( figure 1 The α angle) is 30-60 degrees, which can meet the needs of most materials that are easy to self-polymerize.

[0026] In the present invention, the overflow weir 2 is arranged obliquely along the flow direction of the material, the angle between the overflow weir 2 and the plate body 1 is increased, and a unique flow field effect can be formed, which not only overcomes the retention, but also eliminates the tower The flow gradient on the plate strengt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com