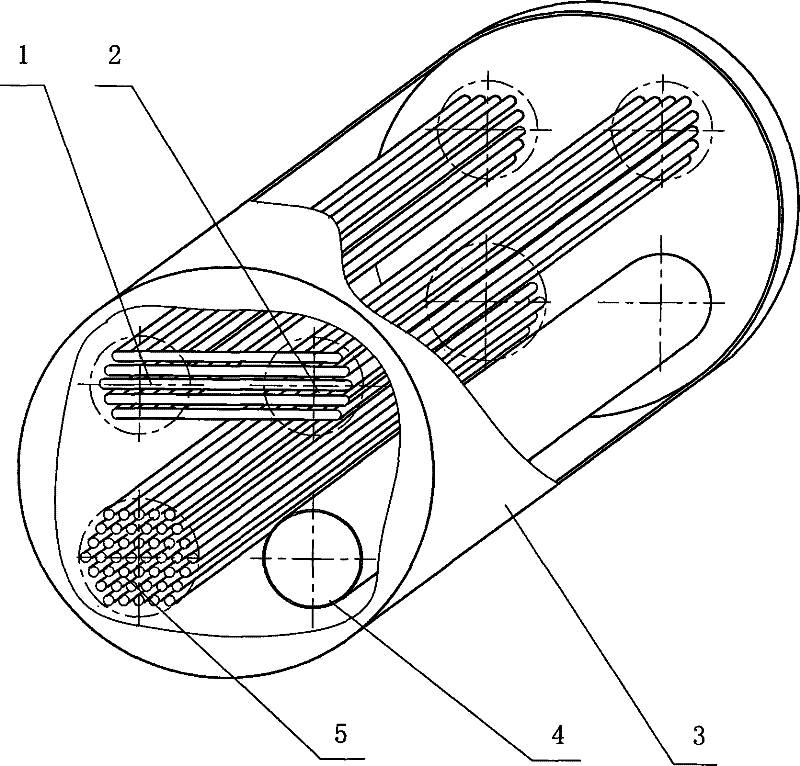

Cylinder type gas heating stove heat flow field improvement structure

A technology of gas heating and improved structure, which is applied in the direction of air heaters, fluid heaters, heat storage heaters, etc., which can solve the problem of reducing the effective use of the heating surface and the heating surface, unable to realize the user's convective heat transfer mode, and not conducive to energy saving Consumption reduction and environmental protection and other issues, to achieve the effect of eliminating the dead angle of the heat flow field, simple structure, easy to popularize and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

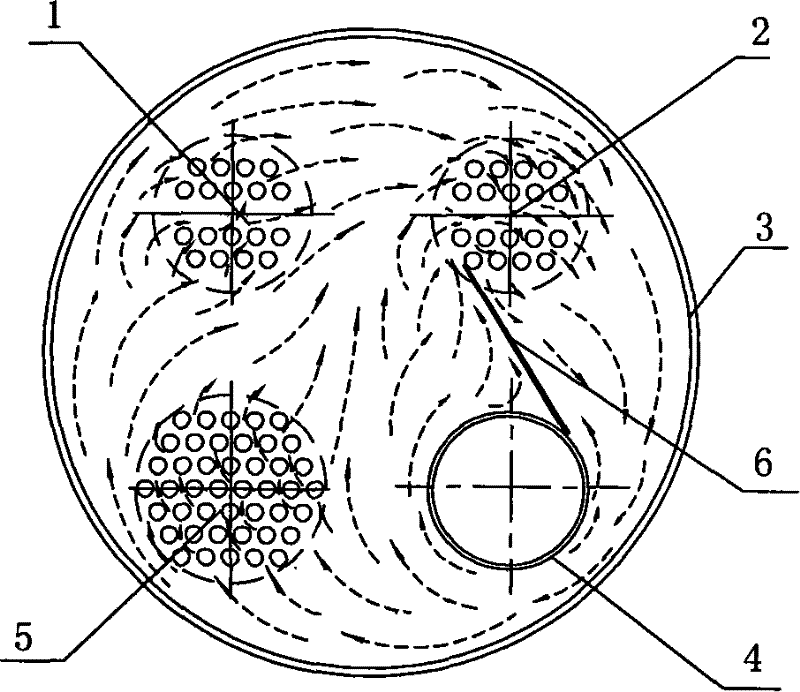

Embodiment 1

[0031] Depend on image 3As shown, in the large cylinder 3 with a length of 2.65 meters and a diameter of 1.22 meters, a flat-plate deflector is arranged along one side of the axial direction of the large cylinder, that is, between the heating gas feeding flow channel 4 and the heating gas sending flow channel required for transportation. 2, a single-side deflector 6 is set, and the heating surface and the heating surface in the large cylinder 3, due to the thermal pressure and the action of the deflector, make the intermediate heat-carrying medium form a heat flow field that circulates smoothly in a clockwise direction, eliminating "dead angles", Achieve enhanced heat transfer and uniform heating.

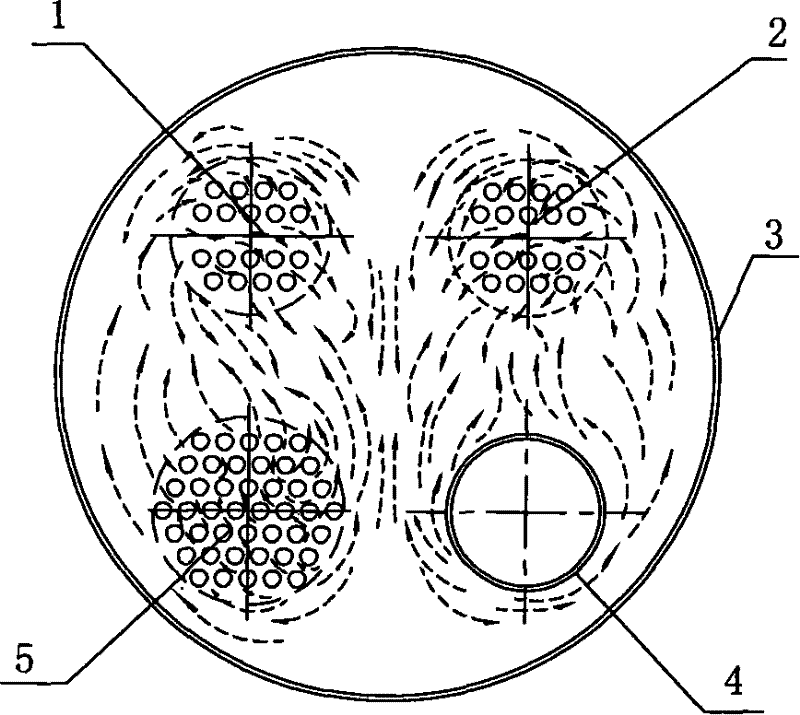

Embodiment 2

[0033] Depend on Figure 8 As shown, in the large cylinder 3 with a length of 2.65 meters and a diameter of 1.22 meters, flat-plate deflectors are arranged on both sides along the axial direction of the large cylinder, that is, when the heated gas is sent into the flow channel 4 and the heated gas is sent out of the flow channel required for transportation. 2 rooms, and the heating gas sending flow channel 5 and the heating gas sending channel 1 required for transportation, and a deflector 6 is arranged between the upper and lower flow channels corresponding to the left and right sides, and the configured deflector 6 The left side is up, right, down, left, and the right side is up, left, down, and right. The heating surface and the heating surface in the large cylinder 3 are thermally compressed and the deflectors make the middle heat-carrying medium form a heat flow field of two left and right eddy currents.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com