Cylinder type gas heating stove improvement structure

A technology of gas heating and improved structure, which is applied in the direction of air heaters, fluid heaters, heat storage heaters, etc., which can solve the problem of reducing the effective use of the heating surface and the heating surface, unable to realize the user's convective heat transfer mode, and not conducive to energy saving Consumption reduction and environmental protection and other issues, to achieve the effect of simple structure, easy promotion and use, and small investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

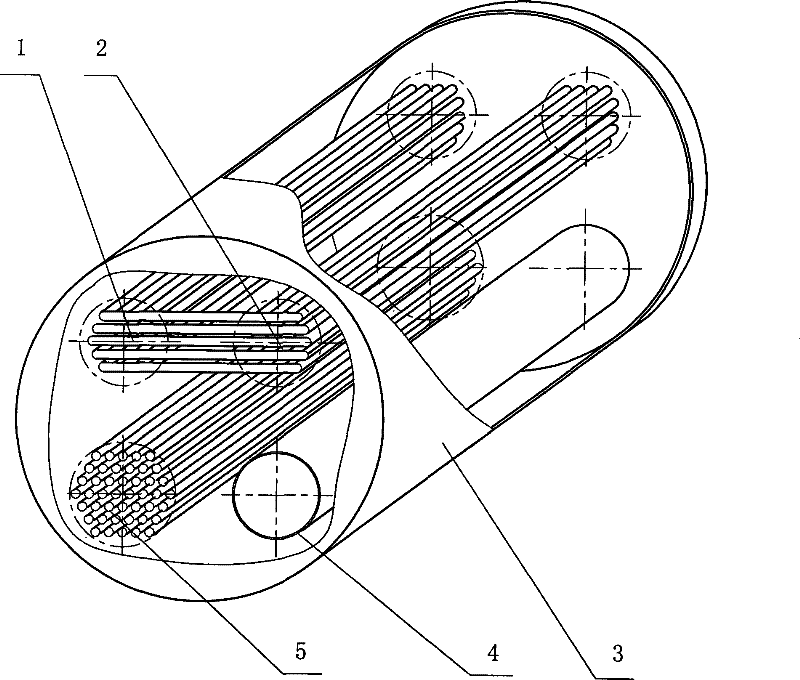

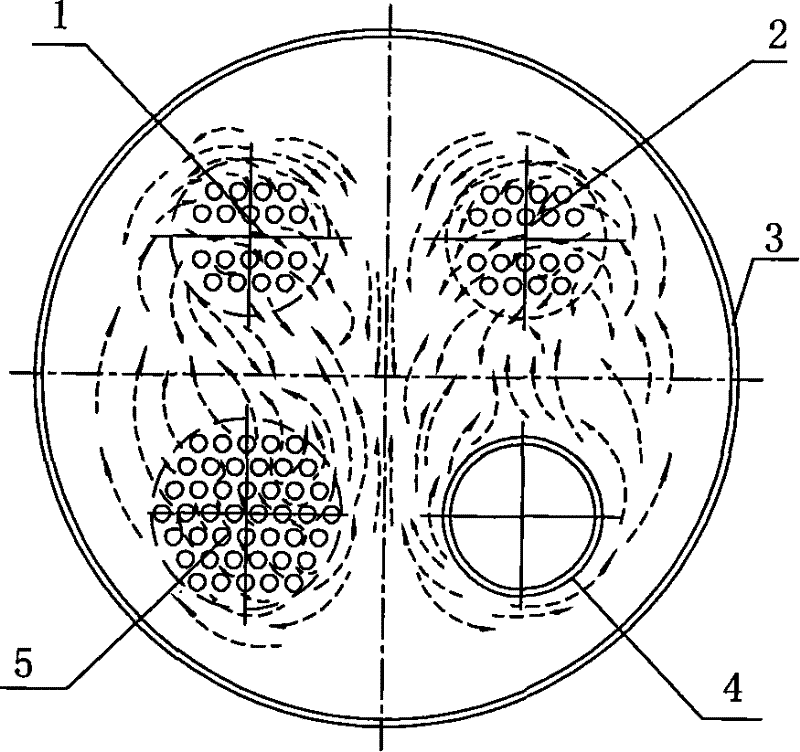

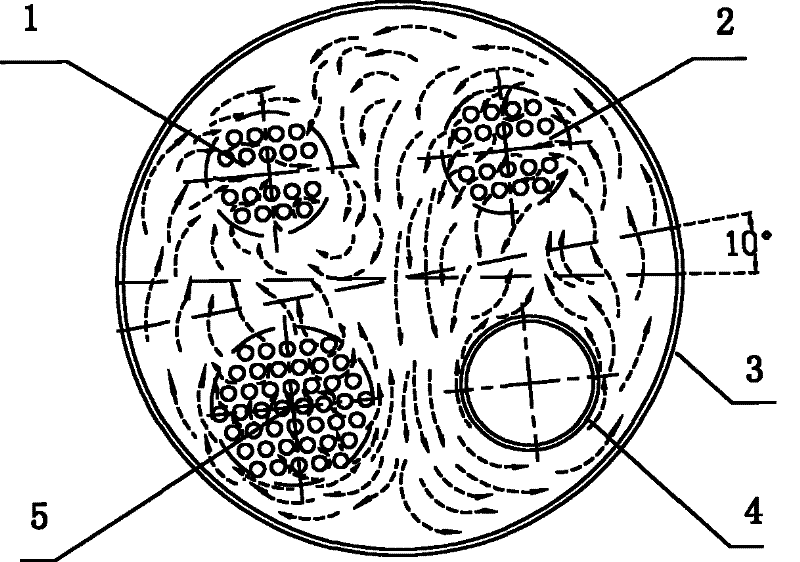

[0025] Example 1, such as Figure 4 As shown, in a large cylinder 3 with a length of 2.65 meters and a diameter of 1.22 meters, on a cross section perpendicular to the axis with the axis as the origin, a flow channel is respectively set in four quadrants divided by vertical orthogonal lines , and the two upper and lower flow channels are connected at one end of the large cylinder, and the openings at the other end are the input port and the output port respectively. The heating gas is sent out of the flow channel 2, and the gas to be heated is natural gas. The two lower flow channels are heating gas flow channels, and the lower heating gas is sent into the flow channel 4 as a pipe structure, and the burning of natural gas produces high-temperature flue gas, and the heated gas is sent into the flow channel 4 for heating, commonly known as "fire tube", and the rest , including the upper two channels for conveying the heated gas and the lower channel for sending out the heated g...

Embodiment 2

[0026] Example 2, such as image 3As shown, in a large cylinder 3 with a length of 2.65 meters and a diameter of 1.22 meters, on a cross section perpendicular to the axis with the axis as the origin, a flow channel is respectively set in four quadrants divided by vertical orthogonal lines , and the two upper and lower flow channels are connected at one end of the large cylinder, and the openings at the other end are the input port and the output port respectively, and the upper two flow channels are the input flow channel 1 and the output flow channel respectively Road 2, the gas to be heated is natural gas. The two lower flow channels are heating gas flow channels. The lower heating gas feeding flow channel 4 is a pipe structure with a diameter of 33 cm, and the combustion of natural gas produces high-temperature flue gas, which is sent into the flow channel 4 for heating by the heating gas, and the rest , including the upper two transport gas channels and the lower heating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com