Tobacco seedling transplanting equipment integrating punching, transplanting and spraying functions

A technology of tobacco seedlings and water outlet holes, which is applied in transplanting machinery, pressurized spreading method of liquid fertilizer, cultivation and other directions, can solve the problem that transplanted tobacco seedlings are not easy to take root and survive, the soil structure of the transplanted hole wall is tight, and the water in the well is easy. problems such as loss, to achieve the effect of improving the level of standardized production, improving the efficiency of transplanting, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

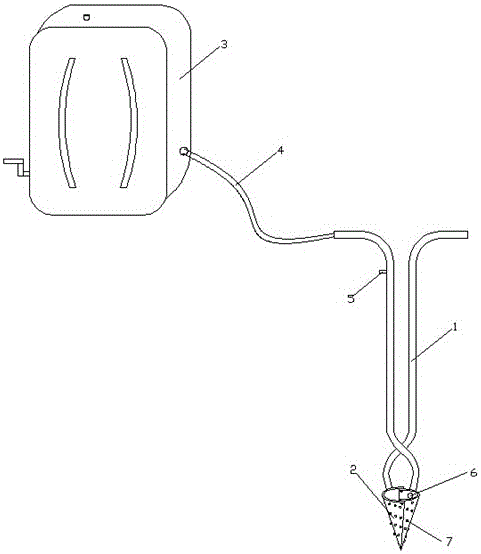

[0019] refer to figure 1 , the tobacco seedling transplanter of the present invention comprises operating rod, perforating cone, knapsack pressure device 3, outlet pipe 4, water injection switch 5, water outlet hole 6 and particle protrusion 7, wherein operating rod is formed by two mutually penetrating pliers Composed of handles 1, the punching cone is composed of two cones 2 that are movably connected together, and the upper parts of the two cones 2 are respectively connected with a handle 1, so that when the two handles 1 are closed, the two cones 2 can be A cone is formed; when the two handles 1 are separated, the lower parts of the two cones 2 are separated from each other and stretched apart.

[0020] The handle 1 is an inner hollow handle, the diameter of the perforated cone is 9 cm, and the height is 17 cm. Several particle protrusions 7 are inlaid or arranged on the outer surfaces of the two cone pieces 2, wherein the particle protrusions 7 are evenly distributed on ...

Embodiment 2

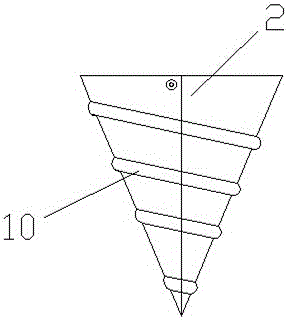

[0026] Such as figure 2 As shown, the particle protrusions 7 are changed to protruding spiral wheel stems 10, and the rest are the same as in Example 1.

Embodiment 3

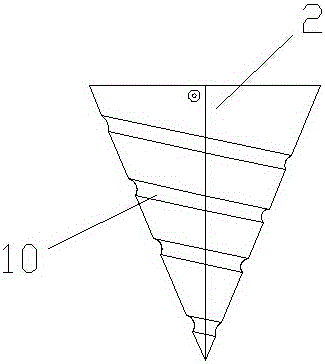

[0028] Such as image 3 As shown, the particle protrusion 7 is changed to an indented spiral wheel stem 10, and the rest is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com