Lithium ion battery negative material Li4Ti5O12 / TiO2 / RGO and preparation method thereof

A technology of lithium-ion batteries and negative electrode materials, applied in battery electrodes, secondary batteries, nanotechnology for materials and surface science, etc., to achieve good electrochemical performance, increase specific surface area, and high specific capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

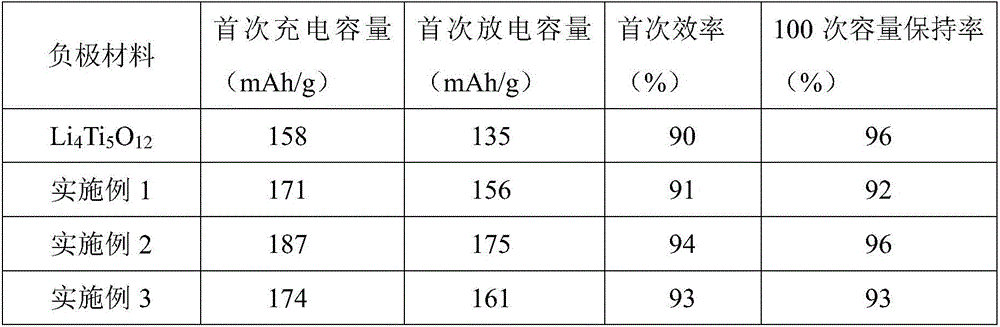

Examples

preparation example Construction

[0024] In order to further improve the application range of lithium-ion battery negative electrode materials and the problems of complex preparation process and difficult control in the preparation method, this embodiment provides a lithium-ion battery negative electrode material Li 4 Ti 5 o 12 / TiO 2 The simple preparation method of / RGO comprises the following steps:

[0025] 1) Using high-purity graphite as raw material, graphene oxide (GO) was prepared by the improved Hummers method. Subsequently, 30ml 30%HI / H 2 O solution was added to 10ml graphene oxide suspension (2.5mg·ml -1 ), stirred and reacted at 70°C for 1 h; subsequently, washed three times with deionized water and absolute ethanol, and dried in vacuum at 70°C to obtain the intermediate product reduced graphene oxide (RGO).

[0026] 2) At room temperature, take an appropriate amount of tetrabutyl titanate (TBT) and RGO powder in absolute ethanol, stir and mix thoroughly for 1 h; then CH 3 COOLi·2H 2 O was ...

Embodiment 1

[0036] Embodiment 1 A kind of lithium ion battery negative electrode material Li 4 Ti 5 o 12 / TiO 2 / RGO

[0037] Follow the steps below to prepare:

[0038] 1) Using high-purity graphite as raw material, graphene oxide (GO) was prepared by the modified Hummers method. Subsequently, 30% HI / H 2 O solution was added to the graphene oxide suspension (2.5mg·ml -1 ), stirred and reacted at 70°C for 1 h; subsequently, washed three times with deionized water and absolute ethanol, and dried in vacuum at 70°C to obtain the intermediate product reduced graphene oxide (RGO).

[0039] 2) At room temperature, take an appropriate amount of tetrabutyl titanate (TBT) and RGO powder in absolute ethanol, stir and mix thoroughly for 1 h; then CH 3 COOLi·2H 2 O was dissolved in an appropriate amount of deionized water, fully dissolved, added to the above solution, and reacted for 10-12 hours under dry conditions to obtain a mixed reaction solution, and CH 3 COOLi·2H 2 The two raw materi...

Embodiment 2

[0042] Embodiment 2 A kind of lithium ion battery negative electrode material Li 4 Ti 5 o 12 / TiO 2 / RGO

[0043] Only change the calcining temperature in step 4) of Example 1: calcining at 590-600°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com