Source electrode driving module power supply circuit, display panel and display device

A technology of power supply circuit and source drive, applied in static indicators, instruments, etc., can solve the problems of source drive module circuit burnout, AVDD high current, source drive module circuit burnout, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

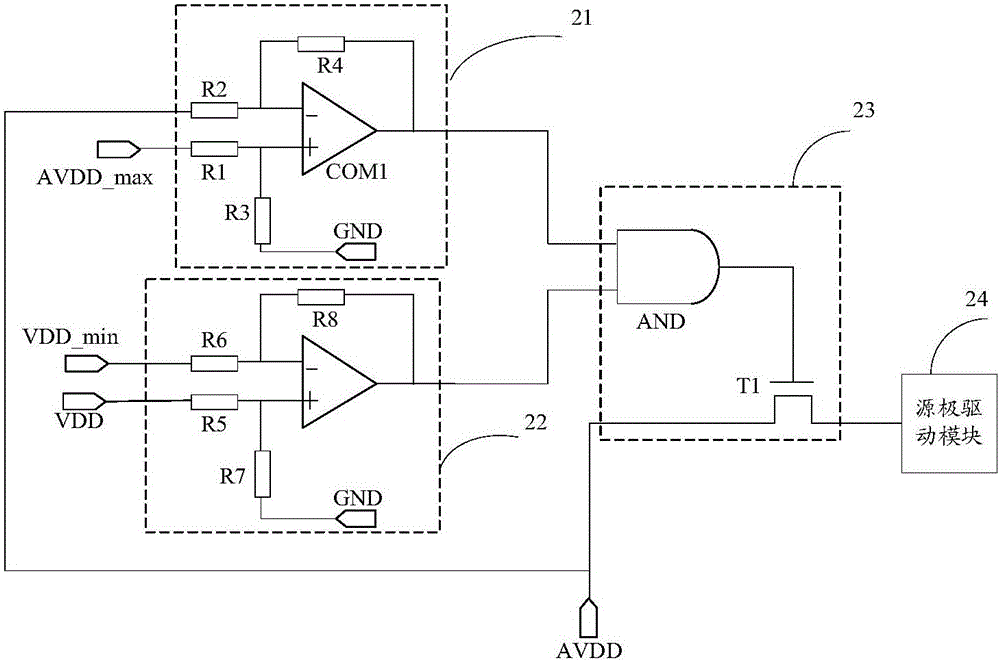

[0095] by Figure 5 The structure of the power supply circuit shown is taken as an example to describe its working process, in which Figure 5 In the power supply circuit shown, the first switching device T1 and the second switching device T2 are both N-type transistors, and each N-type transistor is turned on under the action of a high level and turned off under the action of a low level.

[0096] When AVDD is less than AVDD_max, the first comparator COM1 outputs a high level and supplies it to the first input terminal of the AND gate; when VDD is greater than VDD_min, the second comparator COM2 outputs a high level and supplies it to the second input of the AND gate At the same time, the AND gate outputs a high level, then the first switching device T1 and the second switching device T2 are turned on, and both the digital voltage signal VDD and the analog voltage signal AVDD are input to the source drive module, so when the switch control module outputs digital The voltage ...

Embodiment 2

[0102] by Figure 6 The structure of the power supply circuit shown is taken as an example to describe its working process, in which Figure 6 In the power supply circuit shown, the AND gate is set as a NAND gate, the first switching device T1 and the second switching device T2 are both P-type transistors, each P-type transistor is turned on under the action of a low level, and is turned on at a high level cut off under action.

[0103] When AVDD is less than AVDD_max, the first comparator COM1 outputs a high level and provides it to the first input terminal of the NAND gate. When VDD is greater than VDD_min, the second comparator COM2 outputs a high level and provides it to the first input terminal of the NAND gate. At the two input terminals, at the same time, the NAND gate outputs a low level, then the first switching device T1 and the second switching device T2 are turned on, and both the digital voltage signal VDD and the analog voltage signal AVDD are input to the sourc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com