Wide range fiber grating displacement sensor capable of adjusting measuring range and precision

A technology of displacement sensor and optical fiber grating, which is applied in the direction of instruments, measuring devices, optical devices, etc., can solve the problems of small measuring range of optical fiber grating displacement sensor, unable to change the measuring range and precision, etc., and achieve the solution of small measuring range, high precision, The effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

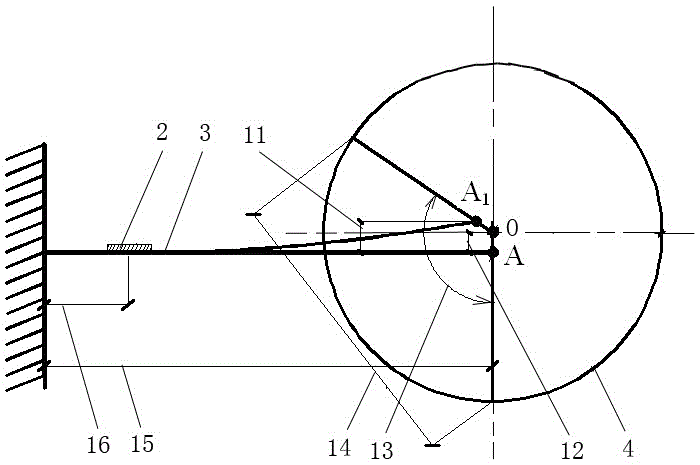

[0020] figure 1 , 2 A large-range fiber grating displacement sensor with adjustable range and precision is shown, including: fiber grating, gear, rack and rectangular outer shell, and the fitting position of the inner wall of the outer shell 1 made of stainless steel plate is fixedly connected with Bracket plate 3, the middle part of the free end of the bracket plate 3 is provided with a groove, and the top of the groove is provided with a sleeve for fitting the rotating shaft 10, and the eccentric point A of the gear 4 passes through the middle part of the rotating shaft 10 and is connected as a whole. 4 The lower end meshes with the rack 7 fixed on the lower pole 8 of the outer shell 1. The width of the rack 7 is greater than the width of the gear 4. One end of the rack 7 is fixedly connected with the measuring rod 6. The cross section of the rack 7 is larger than the measuring rod 6, the measuring rod passes through and protrudes out of the adjacent outer shell 1 side wall...

Embodiment 2

[0022] figure 1 , 2 A large-range fiber grating displacement sensor with adjustable range and precision is shown, comprising: a fiber grating, a spring, and a rectangular outer shell, and a support plate 3 is fixedly connected to the fitting position of the inner side wall of the outer shell 1, and the support plate 3 The middle part of the free end is provided with a groove, and the top of the groove is provided with a sleeve for fitting the rotating shaft 10. The eccentric point of the gear 4 passes through the middle part of the rotating shaft 10 and is connected as one. The lower end of the gear 4 is fixed on the lower part of the outer casing 1 The rack 7 on the pole 8 is engaged, and one end of the rack 7 is fixedly connected with the measuring rod 6, and the measuring rod passes through and extends out of the side wall of the adjacent housing 1 to contact the measured object 5. The rack 7 The other end of the fiber grating (2) is symmetrically arranged on the upper and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com