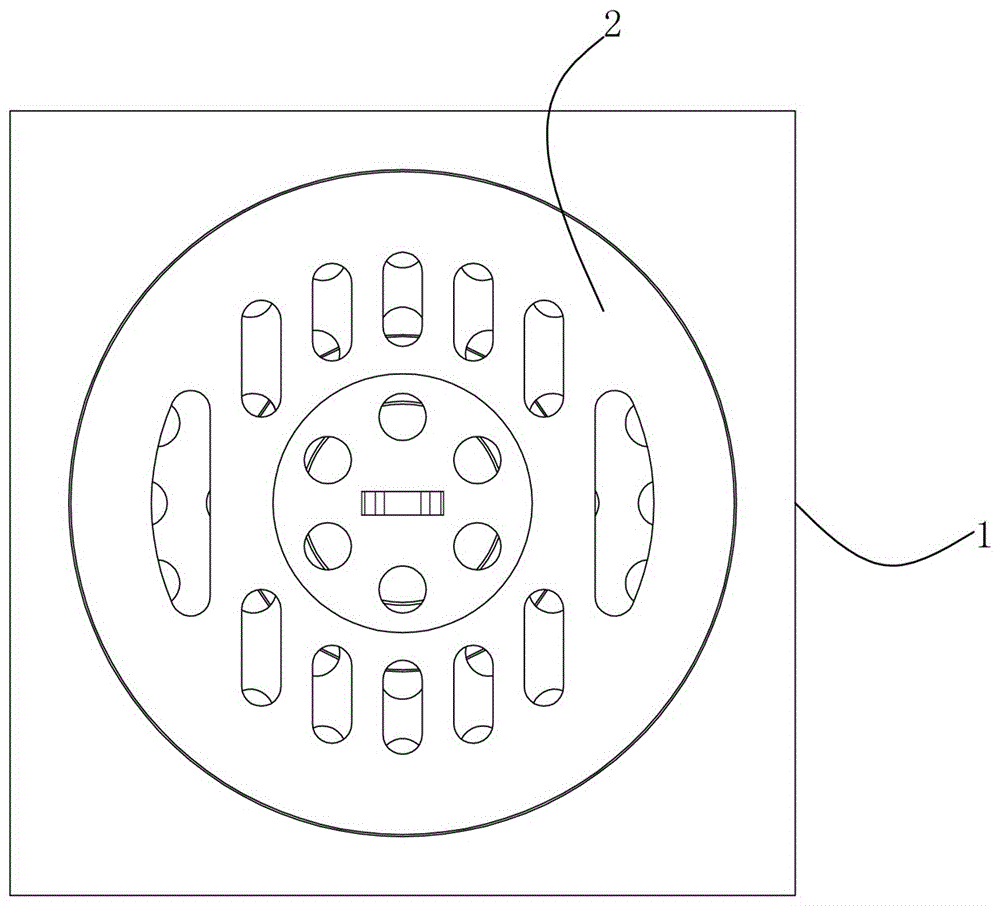

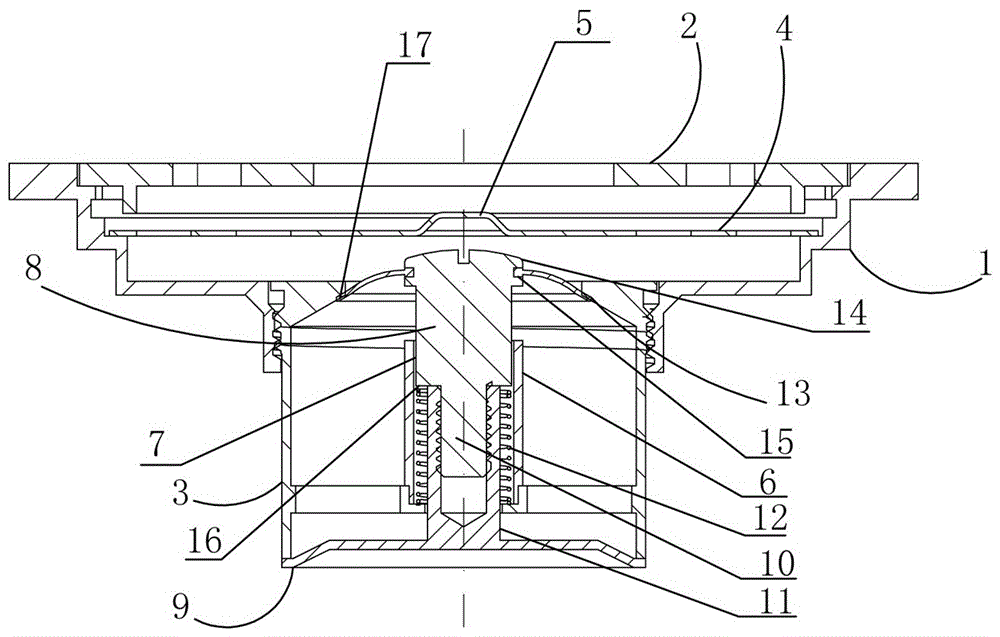

Odor-resistant floor drain

A floor drain and deodorization technology, applied in the field of sanitary ware, can solve the problems of volatilization into the room, troublesome operation, no deodorization, etc., and achieve the effects of high tear resistance, small deformation and strong deodorization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The components and parts by weight of the elastic sealing body 19 are: 70 parts of styrene-butadiene-styrene block copolymer, 10 parts of aromatic oil, 6 parts of polyethylene, 5 parts of aluminum oxide powder, 0.3 parts of diphenylamine 1 part and 1 part of nano silver. The elastic sealing ring 13 is prepared by the following method:

[0035] S1: put hydrogenated nitrile rubber particles into material box 1 and heat until the material is melted, and then molded into ring-shaped connection part 18 by injection molding machine;

[0036] S2: taking out the annular connection part injection-molded in S1 and placing it in the mold cavity for injection-molding the elastic sealing body 19;

[0037] S3: According to the components and parts by weight of the above elastic sealing body 19, take the raw materials and put them into the second material box for uniform mixing, and heat the second material box until the material melts, and then use the injection molding machine to m...

Embodiment 2

[0040] The components and parts by weight of the elastic sealing body 19 are: 70 parts of styrene-butadiene-styrene block copolymer, 16 parts of aromatic oil, 6 parts of polyethylene, 4 parts of aluminum oxide powder, 0.2 parts of diphenylamine 1 part and 1 part of nano silver. The elastic sealing ring 13 is prepared by the following method:

[0041] S1: put hydrogenated nitrile rubber particles into material box 1 and heat until the material is melted, and then molded into ring-shaped connection part 18 by injection molding machine;

[0042] S2: taking out the annular connection part injection-molded in S1 and placing it in the mold cavity for injection-molding the elastic sealing body 19;

[0043] S3: According to the components and parts by weight of the above elastic sealing body 19, take the raw materials and put them into the second material box for uniform mixing, and heat the second material box until the material melts, and then use the injection molding machine to m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com